Method for realizing large-scale preparation of monolayer oxidized graphene

A technology for large-scale preparation of graphene, which is applied in the field of large-scale preparation of single-layer graphene oxide, can solve problems such as unsuitable for popularization and application, good dispersion and good film-forming properties, and achieve low raw material cost, good reproducibility, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

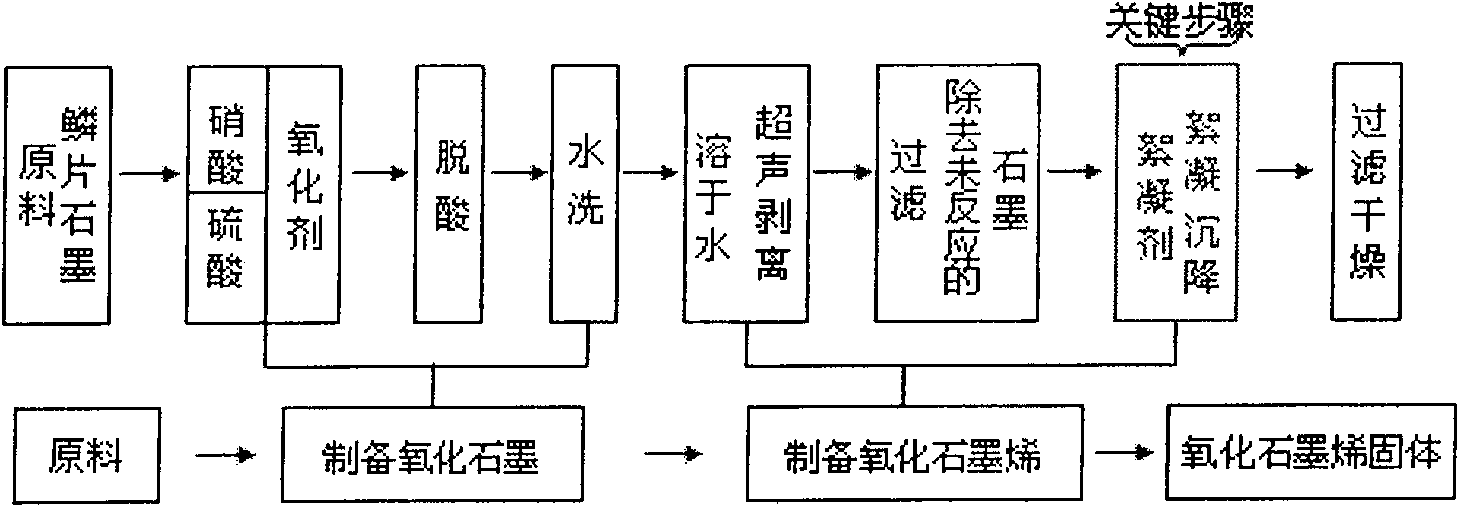

[0025] Embodiment 1, the first step, preparation of graphite oxide: 2 grams of natural graphite flakes were dispersed under stirring into the mixed acid of 35 milliliters of concentrated sulfuric acid and 18 milliliters of concentrated nitric acid which were stirred and cooled in an ice bath for 15 minutes. Slowly add potassium chlorate 22g then, whole reaction system keeps open, and is equipped with tail gas absorption device. The reaction lasted 96 hours. After the reaction was finished, the mixture was washed with 1 liter of deionized water and filtered until neutral.

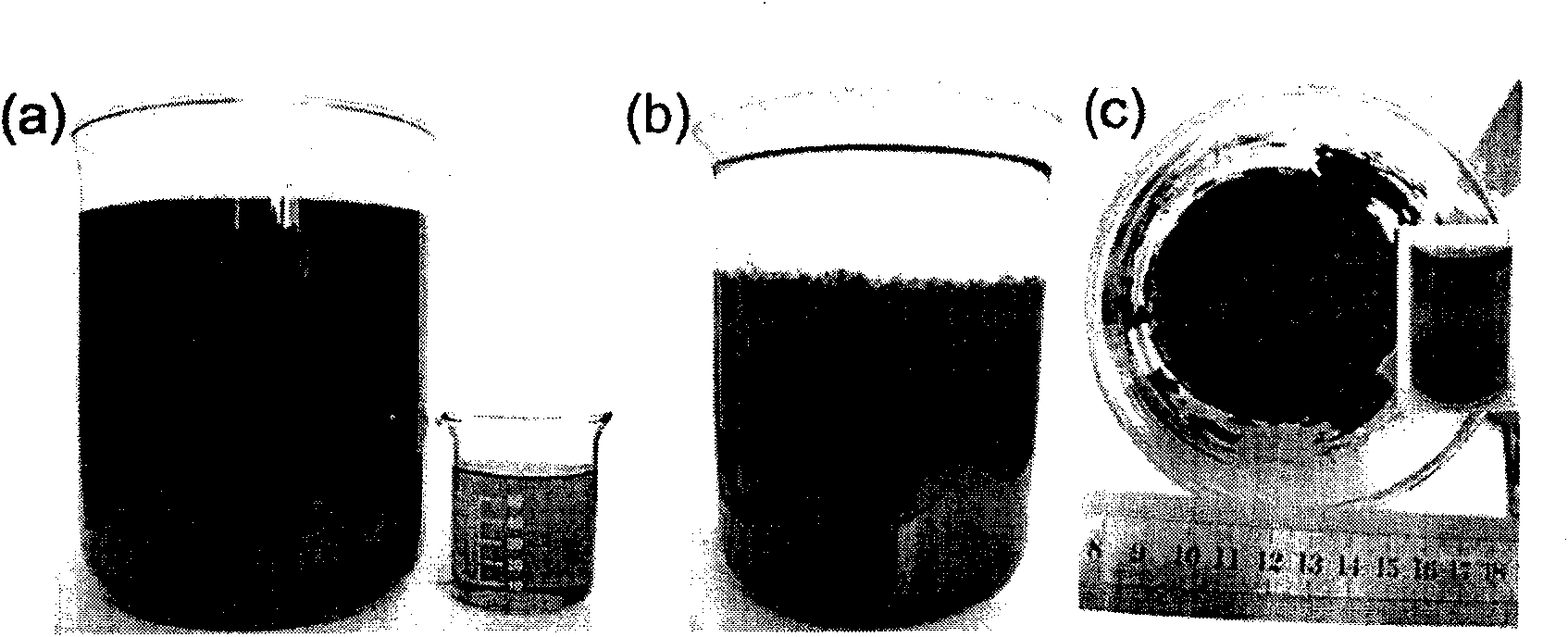

[0026] The second step, dispersing and peeling: add the washed graphite oxide to deionized water immediately, dilute to a concentration of 0.5 g / L, and use ultrasonic waves to disperse and peel for 1 hour after dilution. Then filter to remove unreacted graphite, collect the filtrate to obtain as figure 2 The aqueous solution of graphene oxide shown in a, the solution in the small beaker is: the solution d...

Embodiment 2

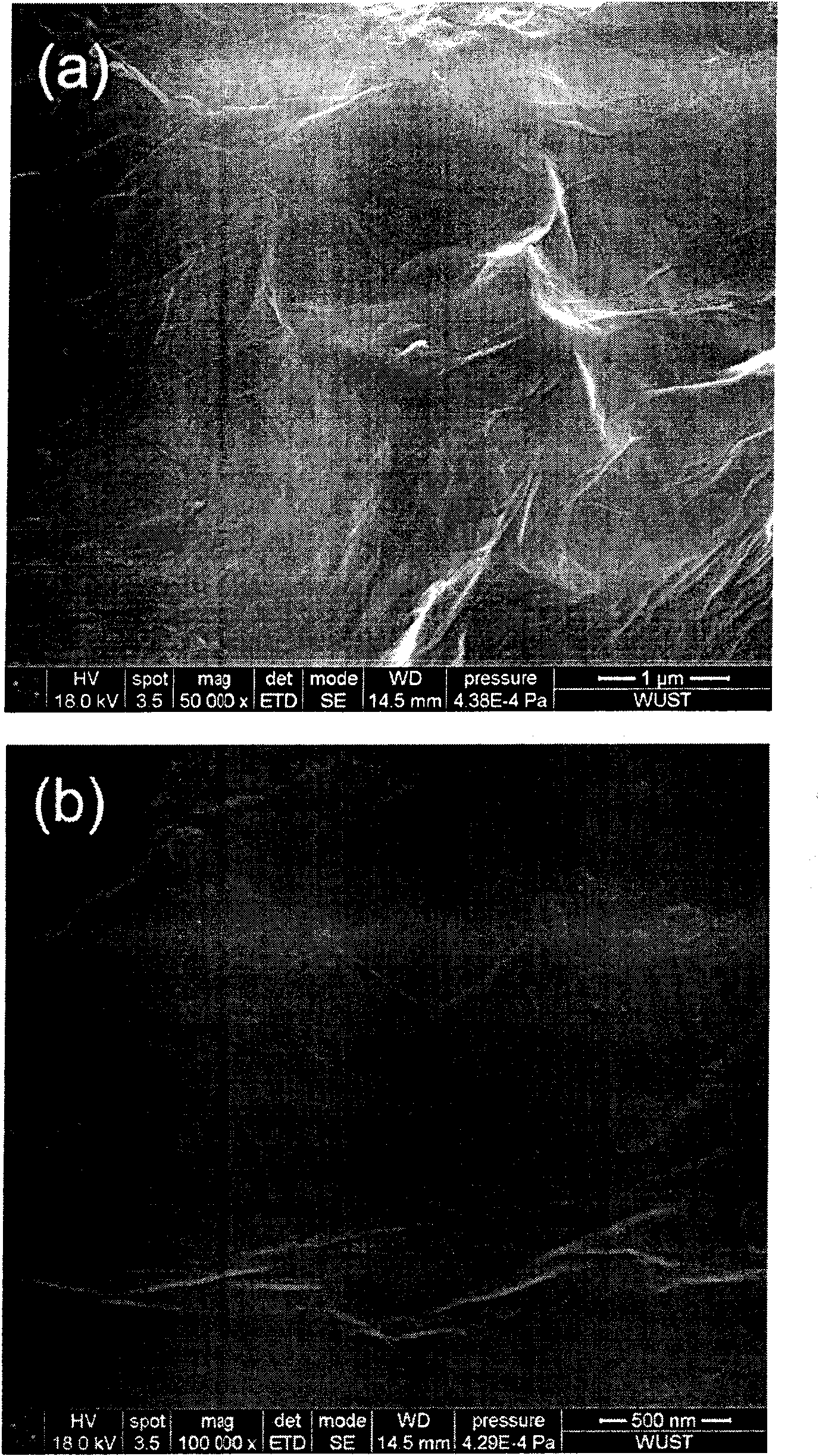

[0028] Embodiment 2, by the preparation method of embodiment 1, just described oxidizing agent is 10 gram potassium permanganate, obtain as follows equally image 3 , 4 , 5, 6, and 7 show the results.

Embodiment 3

[0029] Embodiment 3, by the preparation method of embodiment 1, just described oxidizing agent is 15 gram potassium persulfates, equally obtains as image 3 , 4 , 5, 6, and 7 show the results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com