Oil-displacing agent and oil-displacing method for enhancing recovery ratio of high-temperature, high-salinity and high-hardness reservoir crude oil

A high-temperature, high-salt, oil-displacing agent technology, applied in chemical instruments and methods, production fluids, earthwork drilling and production, etc., can solve problems such as poor temperature resistance, salt resistance, hardness resistance, high concentration, and low oil displacement efficiency. Achieve excellent performance, improve comprehensive performance, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] [Example 1] compatibility experiment

[0032] The components of the oil displacing agent are as follows:

[0033] Amine oxide type amphoteric surfactant I, in formula (1), R 1 for C 12 h 25 -, R 2 for -CH 2 -CH 2- .

[0034] Alkylphenol polyoxyethylene ether carboxylate I, in formula (2), R 3 for C 9 h 19- , n=10, M is sodium.

[0035] Water is salinity 12×10 4 mg / L, Ca 2+ +Mg 2+ The total amount of formation water is 8500mg / L.

[0036] The proportion of oil displacing agent is as follows:

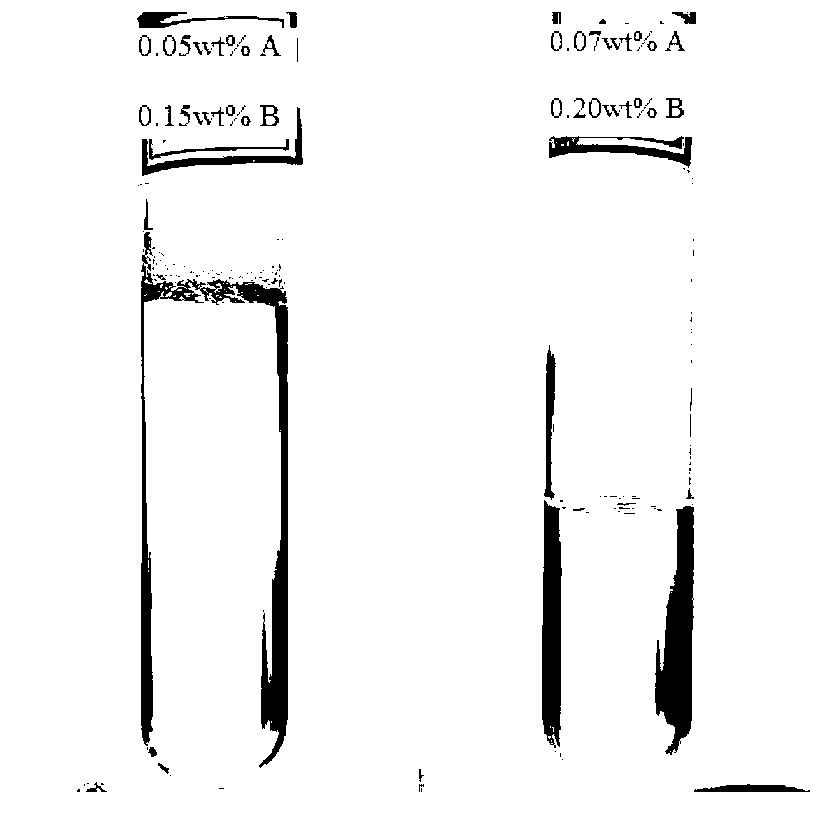

[0037] Oil displacement agent a: amine oxide type amphoteric surfactant 10.05wt%, alkylphenol polyoxyethylene ether carboxylate 10.15wt%, surplus formation water;

[0038] Oil displacement agent b: amine oxide type amphoteric surfactant 10.07wt%, alkylphenol polyoxyethylene ether carboxylate 10.20wt%, surplus formation water.

[0039] Oil displacement agent preparation method:

[0040] Add the amine oxide type amphoteric surfactant I and the alkylphenol polyoxyethyl...

Embodiment 2

[0042] [Example 2] Interfacial tension experiment

[0043] The oil displacement agent was prepared as described in Example 1.

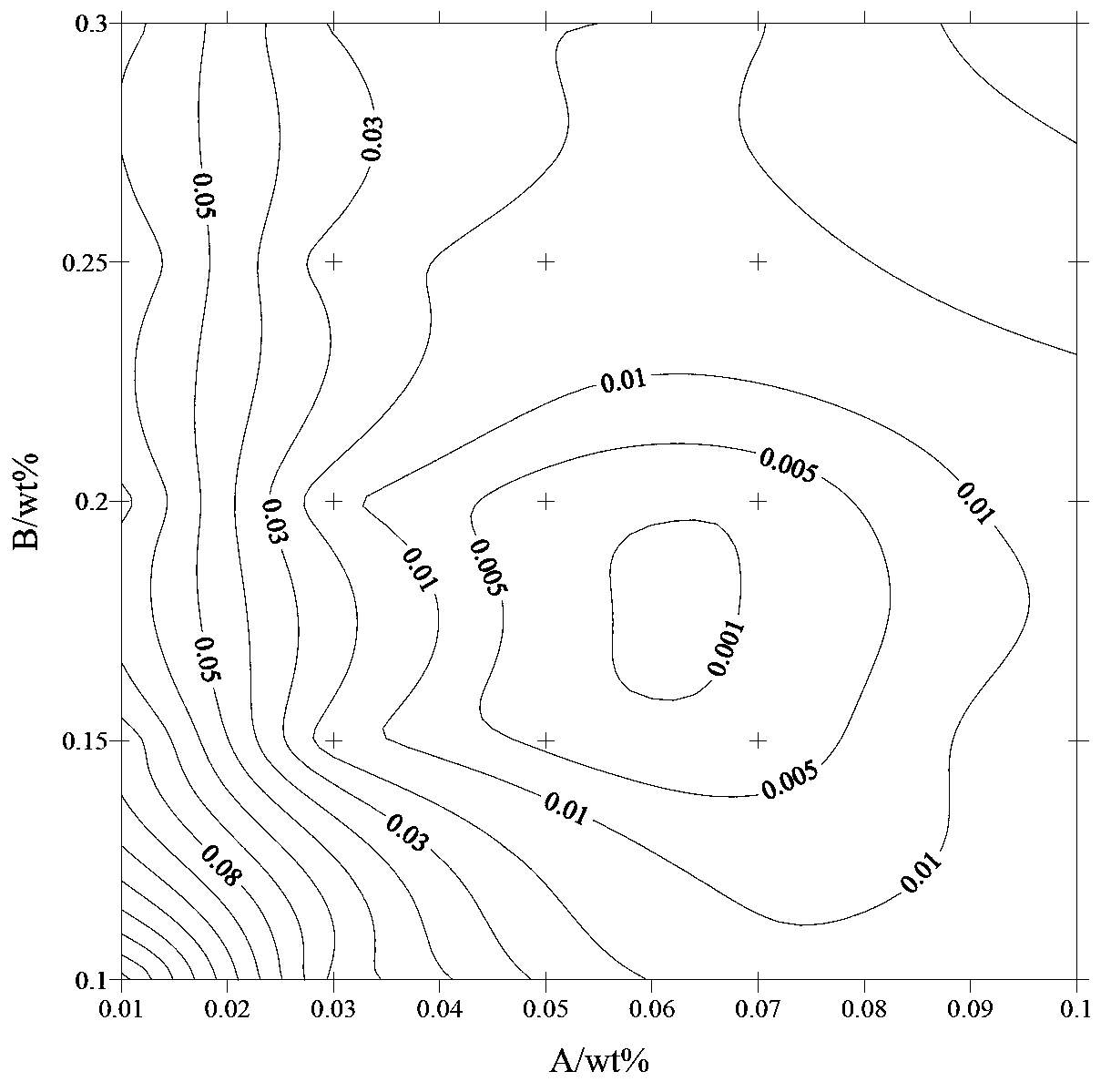

[0044] The interfacial tension between the oil displacement agent and dehydrated and degassed crude oil (viscosity 0.378mPa·s, density 0.825g / mL at 110°C) was measured under reservoir conditions. The experimental results are shown in Table 1 and figure 2 . The interfacial tension was measured by a TX500 spinning drop interfacial tensiometer produced by the University of Texas. From Table 1 and figure 2 It can be seen that the interface of the compound system of 0.05wt%~0.07wt% amine oxide type amphoteric surfactant (A) and 0.15wt%~0.20wt% alkylphenol polyoxyethylene ether carboxylate (B) The tension can be as low as 1.7×10 -3 mN / m.

[0045] Table 1 The interfacial tension of the compound system of amine oxide type amphoteric surfactant (A) and alkylphenol polyoxyethylene ether carboxylate (B)

[0046]

[0047]

Embodiment 3

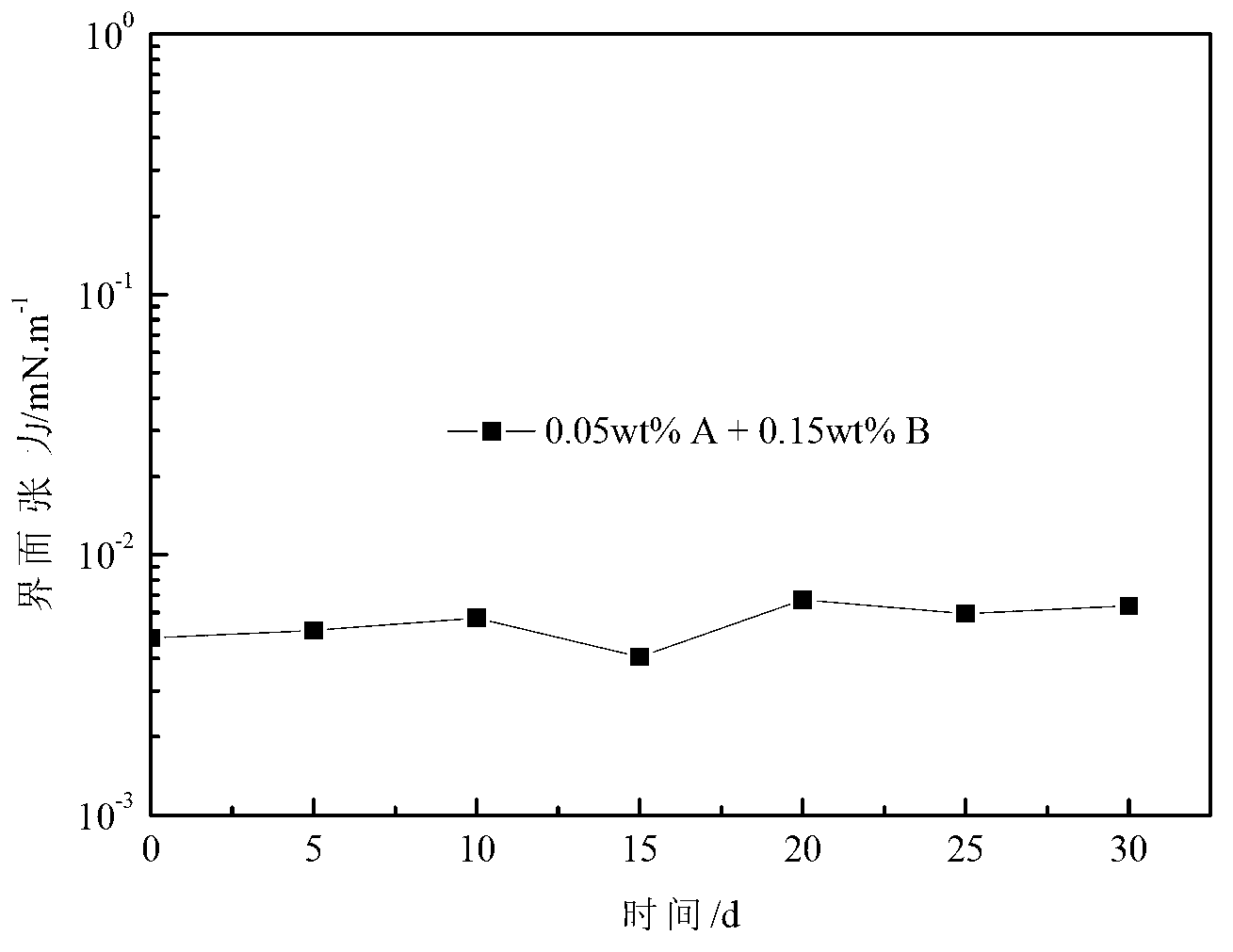

[0048] [Example 3] thermal stability experiment

[0049] The components of the oil displacing agent are as follows:

[0050] Amine oxide type amphoteric surfactant II, in formula (1), R 1 for C 14 h 29 -, R 2 for -CH 2- CH 2- CH 2- .

[0051] Alkylphenol polyoxyethylene ether carboxylate II, in formula (2), R 3 for C 16 h 33- , n=15, M is sodium.

[0052] Water is 12×10 4 mg / L, Ca 2+ +Mg 2+ The total amount of formation water is 8500mg / L.

[0053] Use the formation water to prepare the oil displacement agent solution of the amine oxide type amphoteric surfactant II and the alkylphenol polyoxyethylene ether carboxylate II. In terms of mass percentage, the amine oxide type amphoteric surfactant II, alkyl The ratio of phenol polyoxyethylene ether carboxylate II to formation water is 0.05wt%:0.15wt%:99.80wt%. The oil-displacing agent solution is injected into the ampoule and sealed, packed into a high-temperature aging tank, and placed in a constant temperature dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com