Gemini viscoelastic surfactant and its preparation method, application and steering acid

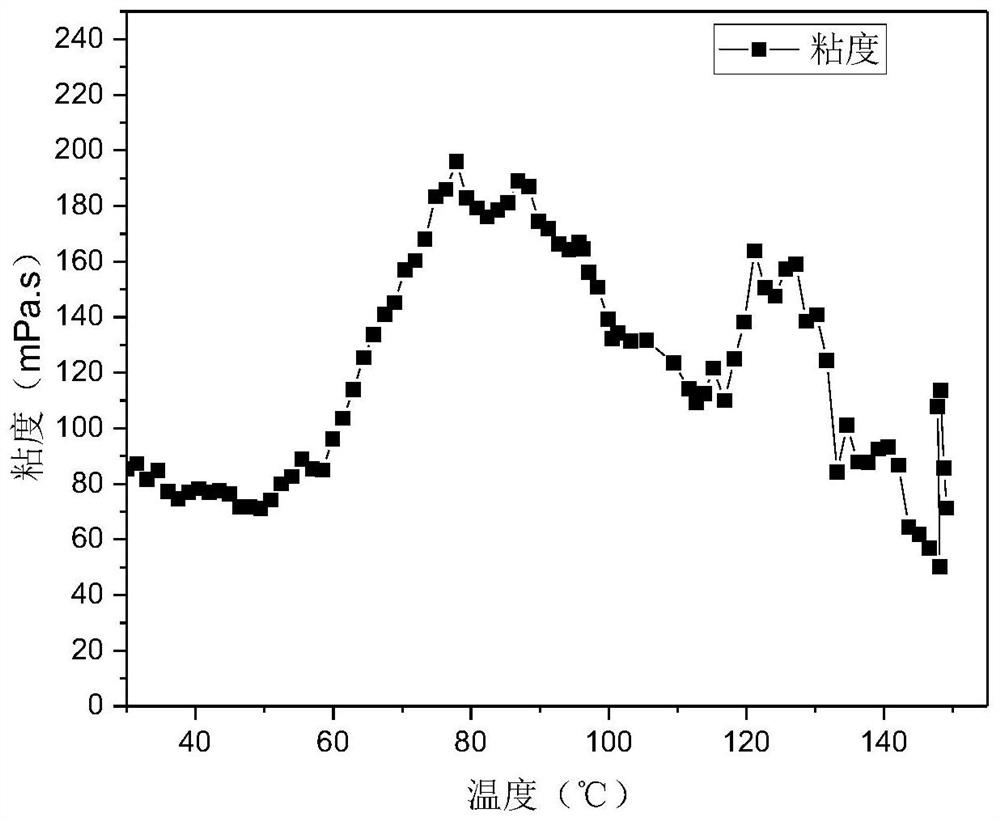

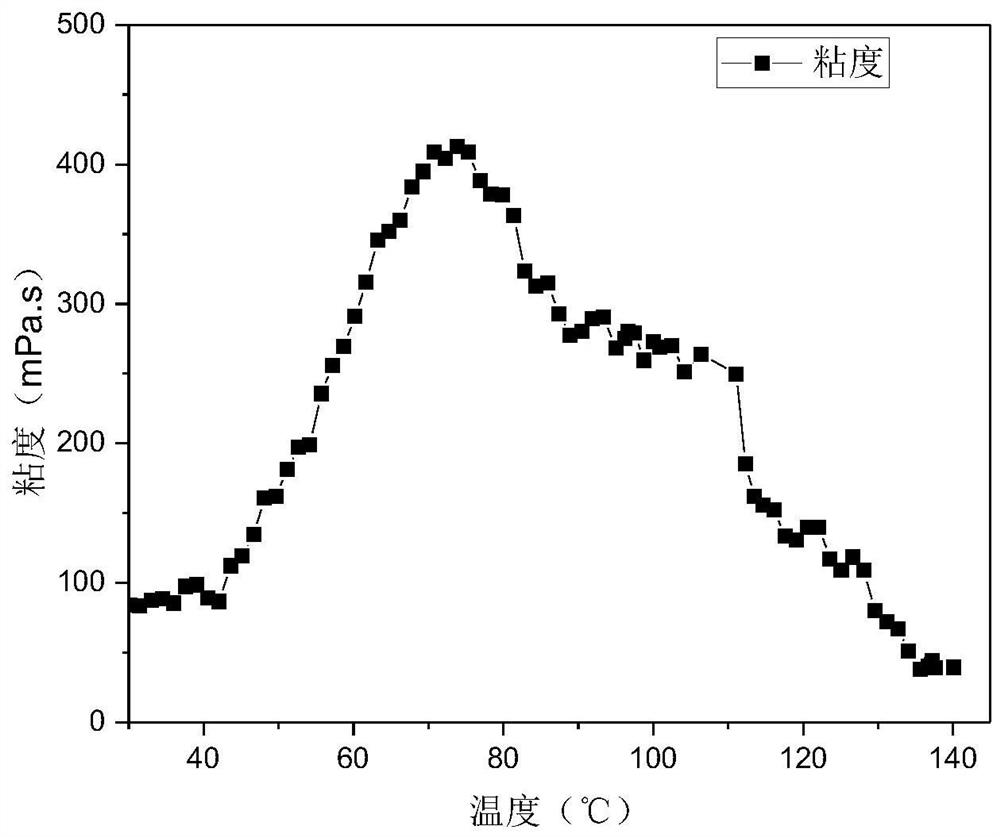

A technology of surfactant and viscoelasticity, which is applied in the field of Gemini viscoelastic surfactant and its preparation, and steering acid, which can solve the problem of temperature resistance lower than 120°C, and achieve good temperature resistance, strong viscosity increasing ability, and formation small damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

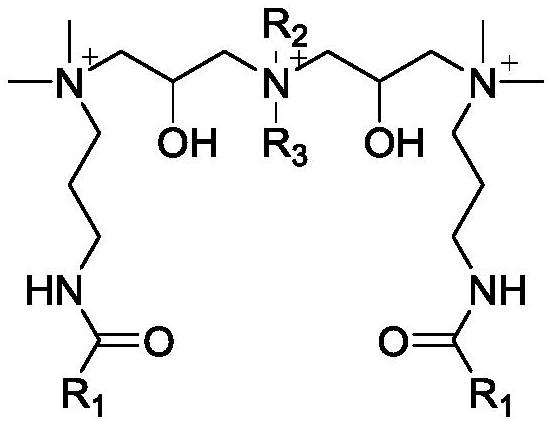

Method used

Image

Examples

Embodiment 1

[0036] (1) Dissolve 0.1mol ethanolamine in absolute ethanol, dissolve 0.1mol 1,3-propane sultone in absolute ethanol, add dropwise ethanolamine alcohol solution, react at room temperature for 12 hours, and remove the solvent by rotary evaporation to obtain intermediate Body A;

[0037] (2) Dissolve 0.1 mol of intermediate A in 50% ethanol solution, add an appropriate amount of concentrated hydrochloric acid and 0.2 mol of epichlorohydrin, react at 70°C for 7 hours, and remove the solvent by rotary evaporation to obtain intermediate product B;

[0038] (3) Dissolve 0.1mol of intermediate product B in ethanol, add 0.21mol of erucamide propyl dimethylamine, add a small amount of sodium hydroxide as a catalyst, and react at 85°C for 24 hours; after the reaction, distill under reduced pressure The solvent was removed to obtain the gemini viscoelastic surfactant VDA-YA.

Embodiment 2

[0040] (1) Dissolve 0.1mol aniline in absolute ethanol, dissolve 0.1mol 1,3-propane sultone in absolute ethanol, add aniline alcohol solution dropwise, react at room temperature for 12 hours, and remove the solvent by rotary evaporation to obtain intermediate Body A;

[0041] (2) Dissolve 0.1 mol of intermediate A in 50% ethanol solution, add an appropriate amount of concentrated hydrochloric acid and 0.2 mol of epichlorohydrin, react at 70°C for 7 hours, and remove the solvent by rotary evaporation to obtain intermediate product B;

[0042] (3) Dissolve 0.1mol of intermediate product B in ethanol, add 0.21mol of erucamide propyl dimethylamine, add a small amount of sodium hydroxide as a catalyst, and react at 85°C for 24 hours; after the reaction, distill under reduced pressure The solvent was removed to obtain the gemini viscoelastic surfactant VDA-YA.

Embodiment 3

[0044] (1) Dissolve 0.1 mol of diethylamine in 50% ethanol solution, add an appropriate amount of concentrated hydrochloric acid and 0.2 mol of epichlorohydrin, react at 70°C for 7 hours, and remove the solvent by rotary evaporation to obtain intermediate product B;

[0045] (2) Dissolve 0.1mol of intermediate product B in ethanol, add 0.21mol of erucamide propyl dimethylamine, add a small amount of sodium hydroxide as a catalyst, and react at 85°C for 24 hours; after the reaction, distill under reduced pressure Remove the solvent to obtain gemini viscoelastic surfactant VDA-YT.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com