Foaming agent for plugging gas channeling in displacement of reservoir oil by using CO2

A foaming agent and gas channeling technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem that the oil displacement foaming agent cannot meet the requirements of blocking gas channeling, so as to improve the effect of CO2 flooding, Enhanced oil recovery and strong foaming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The CO used in this example 2 The foaming agent for blocking gas channeling in oil flooding is characterized in that it consists of the following components by weight: 1.52g of α-olefin sulfonate, 0.76g of carboxylic acid imidazoline amphoteric surfactant, dodecyl di Methyl betaine 1.52g, alkanolamide 0.20g, pure water 996.0g.

[0030] Wherein, the chemical formula of α-olefin sulfonate is:

[0031] C 12 h 25 CH=CHCH 2 SO 3 Na.

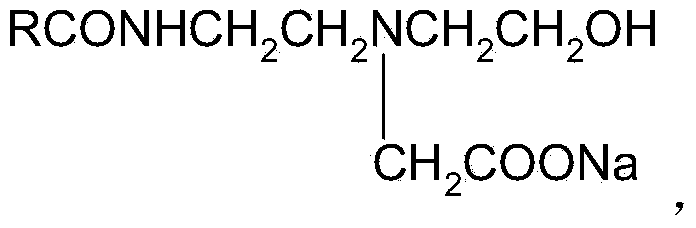

[0032] The chemical formula of carboxylic acid type imidazoline amphoteric surfactant is:

[0033]

[0034] The chemical formula of alkanolamide is:

[0035] C 11 h 23 CON(CH 2 CH 2 Oh) 2 .

[0036] The CO used in this example 2 The preparation method of the foaming agent for blocking gas channeling in oil flooding is: accurately weigh 1.52g of α-olefin sulfonate, 0.76g of carboxylic acid type imidazoline amphoteric surfactant, dodecyl dimethyl betaine 1.52 g and 0.20 g of alkanolamide were successively dissolved in 996.0 g of...

Embodiment 2

[0038] The CO used in this example 2 The foaming agent for blocking gas channeling in oil displacement is characterized in that it consists of the following components by weight: α-olefin sulfonate 1.90g, carboxylic acid imidazoline amphoteric surfactant 0.95g, dodecyl di Methyl betaine 1.90g, alkanolamide 0.25g, simulated brine 995.0g.

[0039] Wherein, the chemical formula of α-olefin sulfonate is:

[0040] C 11 h 23 CH=CHCH 2 SO 3 Na.

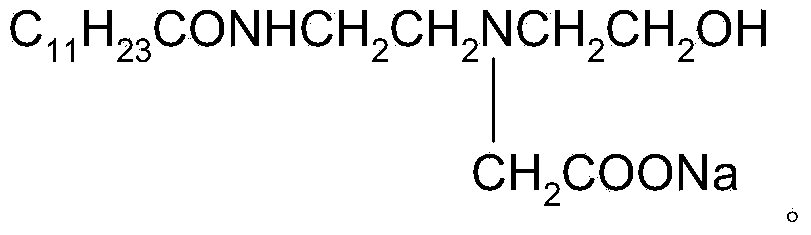

[0041] The chemical formula of carboxylic acid type imidazoline amphoteric surfactant is:

[0042]

[0043] The chemical formula of alkanolamide is:

[0044] C 11 h 23 CON(CH 2 CH 2 Oh) 2 .

[0045] The simulated brine contains the following components by weight percentage: NaCl7.38%, CaCl 2 0.87%, Na 2 SO 4 1.17%, MgCl 20.58%, total salinity 10×10 4 mg / L.

[0046] The CO used in this example 2 The preparation method of the foaming agent for blocking gas channeling in oil displacement is: accurately weigh 1.90 g of α-o...

Embodiment 3

[0048] The CO used in this example 2 The foaming agent for blocking gas channeling in oil flooding is characterized in that it consists of the following components by weight: 2.66g of α-olefin sulfonate, 1.33g of carboxylic acid imidazoline amphoteric surfactant, dodecyl di Methyl betaine 2.66g, alkanolamide 0.35g, pure water 993.0g.

[0049] Wherein, the chemical formula of α-olefin sulfonate is:

[0050] C 12 h 25 CH=CHCH 2 SO 3 Na.

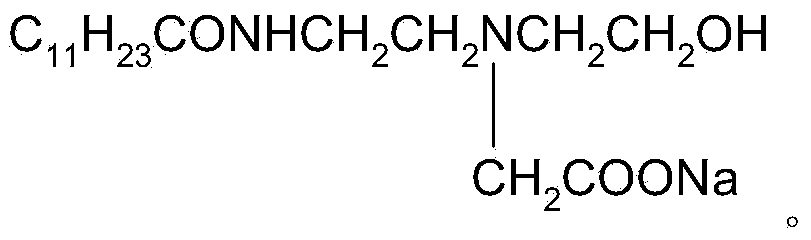

[0051] The chemical formula of carboxylic acid type imidazoline amphoteric surfactant is:

[0052]

[0053] The chemical formula of alkanolamide is:

[0054] C 11 h 23 CON(CH 2 CH 2 Oh) 2 .

[0055] The CO used in this example 2 The preparation method of the foaming agent for blocking gas channeling in oil displacement is: accurately weigh 2.66g of α-olefin sulfonate, 1.33g of carboxylic acid type imidazoline amphoteric surfactant, dodecyl dimethyl betaine 2.66 g and 0.35 g of alkanolamide were successively dissolved in 993.0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com