Hydrophobic associated polymer and preparation method thereof

A hydrophobic association and polymer technology, applied in the field of polymers, can solve problems such as rapid drop in solution viscosity, intolerance to salt, and performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

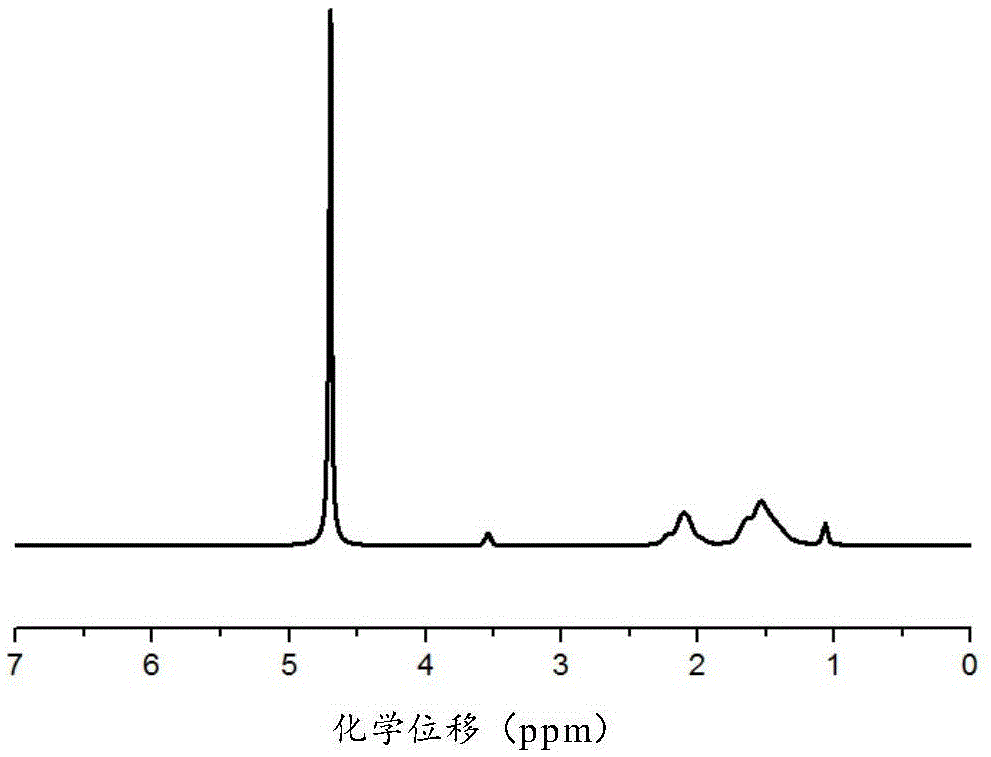

[0054] The present invention also provides a method for preparing the above-mentioned hydrophobic association polymer, comprising: under the action of an initiator, acrylamide monomer and a hydrophobic monomer are subjected to a copolymerization reaction to obtain a hydrophobic association polymer; the hydrophobic monomer is selected from From N-alkyl substituted acrylamide and its derivatives, alkyl acrylate, alkyl methacrylate, fluorine-substituted alkyl acrylate, fluorine-substituted alkyl methacrylate, allyl alkyl quaternary ammonium One or more of salt, acrylamide alkyl sulfonic acid and sulfonate thereof, alkylphenol polyoxyethylene acrylate and polyoxyethylene alkyl acrylate; the viscosity-average molecular weight of the hydrophobic association polymer is 5 to 35 million; the molar ratio of the acrylamide monomer to the hydrophobic monomer is 1: (0.001 to 0.06).

[0055] Wherein, the hydrophobic monomer is the same as described above, and will not be repeated here. Des...

Embodiment 1

[0084] Feed acrylamide and 2-methacryloxyethyl-dimethyl dodecyl ammonium bromide at a molar ratio of 99:1, add them to a 5000ml beaker and prepare the total monomer mass concentration of 24 with pure water. % mixed solution, stirred until dissolved, heated to 45°C in a water bath, adjusted the pH value of the system to 9 with sodium hydroxide solution, added potassium persulfate and sodium thiosulfate composite initiator to initiate polymerization, wherein potassium persulfate and thiosulfate The mass ratio of sodium sulfate is 1:1, and the amount of potassium persulfate added is 0.10% of the monomer mass. The polymerization reaction is carried out in an adiabatic environment, and the polymerization reaction is considered to be basically completed when the temperature of the reaction system does not rise by more than 1°C within 30 minutes. 1 hour after the completion of the polymerization reaction, take out the colloid, cut the colloid into 3-5mm sized particles, add 2.4% hydr...

Embodiment 2

[0088] According to the steps in Example 1, the mass fraction of the total concentration of monomers in the polymerization system was changed to 20%, and the remaining raw materials and additions remained unchanged.

[0089] The viscosity-average molecular weight of the hydrophobic association polymer obtained in Example 2 was measured and calculated according to GB / T12005.10-92 using an Ubbelohde viscometer (0.55 mm diameter) to be 13.5 million.

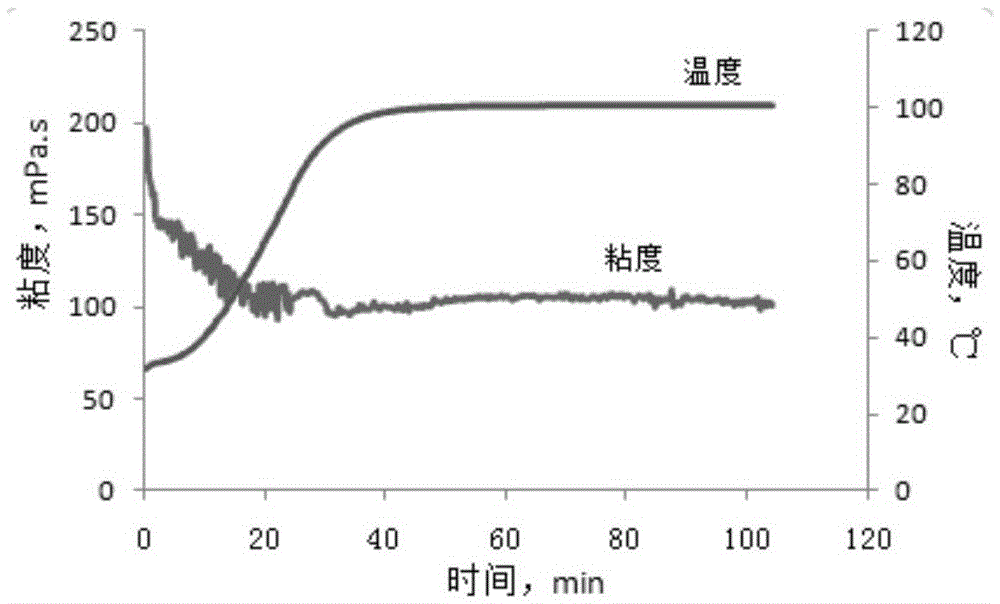

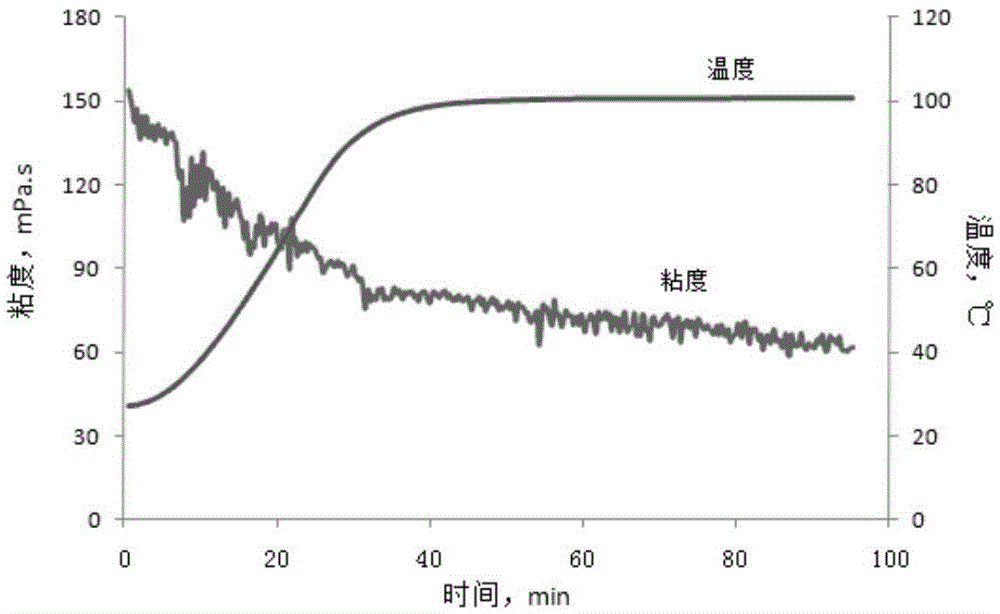

[0090] Using water with a total salinity of 49,000, Ca 2+ , Mg 2+ The simulated brine with a total ion concentration of 2200mg / L and the hydrophobic association polymer prepared in Example 2 prepared a polymer solution with a concentration of 5000mg / L at 50°C, and the dissolution time was 1.9h. When the concentration of the polymer solution was 2000mg / L L, the temperature is 85°C, and the shear rate is 7.34s -1 The viscosity value of the tested polymer was 53mPa·s, and under the condition of 85°C, the 90d viscosity retention rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity value | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com