Hyperbranched hydrophobical-associating water-soluble polymer and its preparation method

A water-soluble polymer, hydrophobic association technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of polymer solution viscosity, elasticity and strength reduction, increase the difficulty of polymerization reaction, and unsatisfactory association To achieve good solubility and temperature and salt resistance, improve salt resistance and shear resistance, good injection ability and fluidity control ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Weigh 3.1 g of skeleton monomer and 2 g of maleic anhydride into different beakers, and then add 20 g and 10 g of dimethyl sulfoxide to dissolve uniformly, and slowly add the dimethyl sulfoxide solution of skeleton monomer Add dropwise to the dimethyl sulfoxide solution of maleic anhydride, vent nitrogen during the dropwise addition, place the system in an ice salt bath, and monitor the reaction progress with the pH value. When the pH of the reaction solution is 4~5 At this time, stop dropping the skeleton monomer solution, continue stirring until the temperature of the reaction liquid system no longer rises, and repeatedly precipitate with chloroform to obtain the functional skeleton monomer.

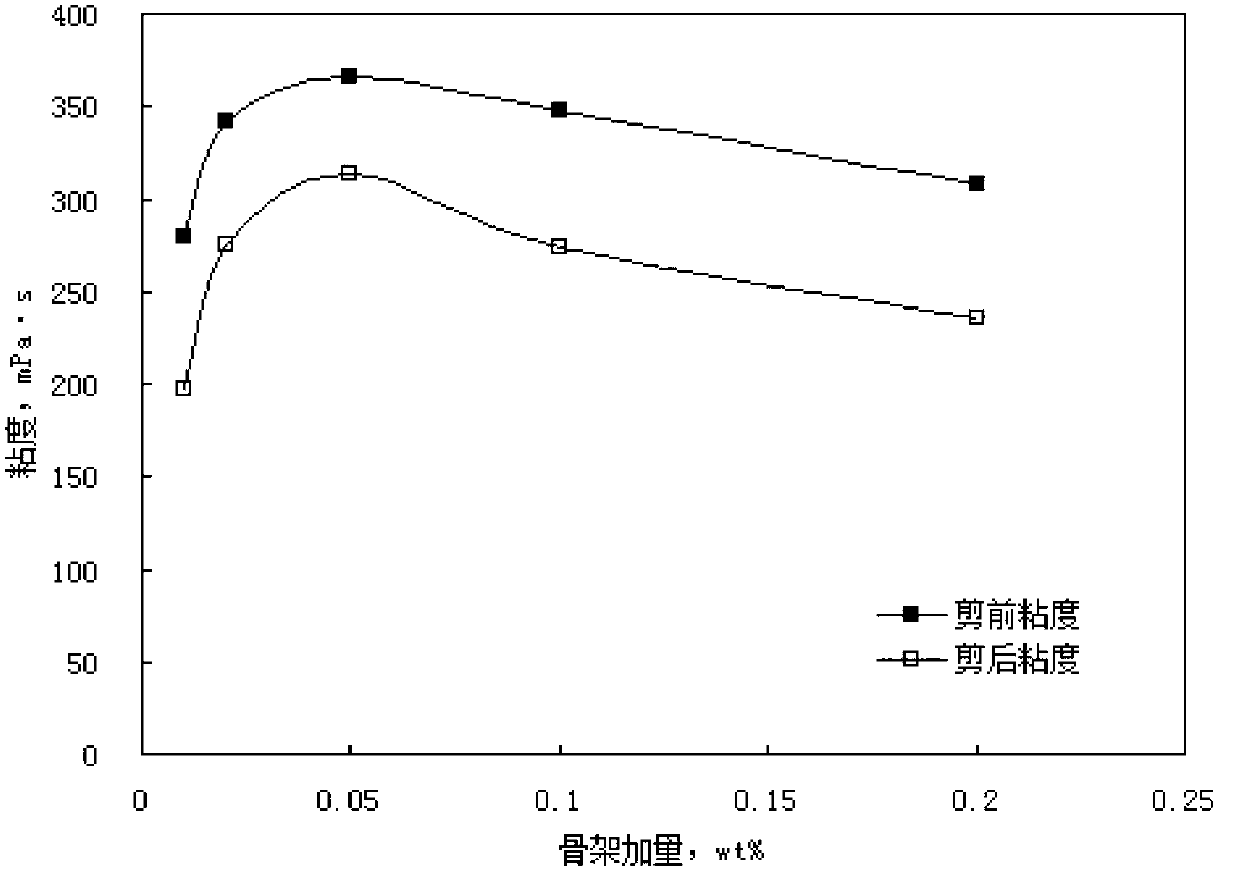

[0043] Weigh 20 grams of acrylamide (AM), 5 grams of acrylic acid (AA), functionalized skeleton monomer 0.0025 grams, 0.005 grams, 0.0125 grams, 0.025 grams, 0.05 grams, dimethylallyl octadecyl ammonium chloride 0.2 grams and 74 grams of distilled water were added to the beaker, st...

Embodiment 2

[0045] The functionalized backbone monomer was prepared as in Example 1.

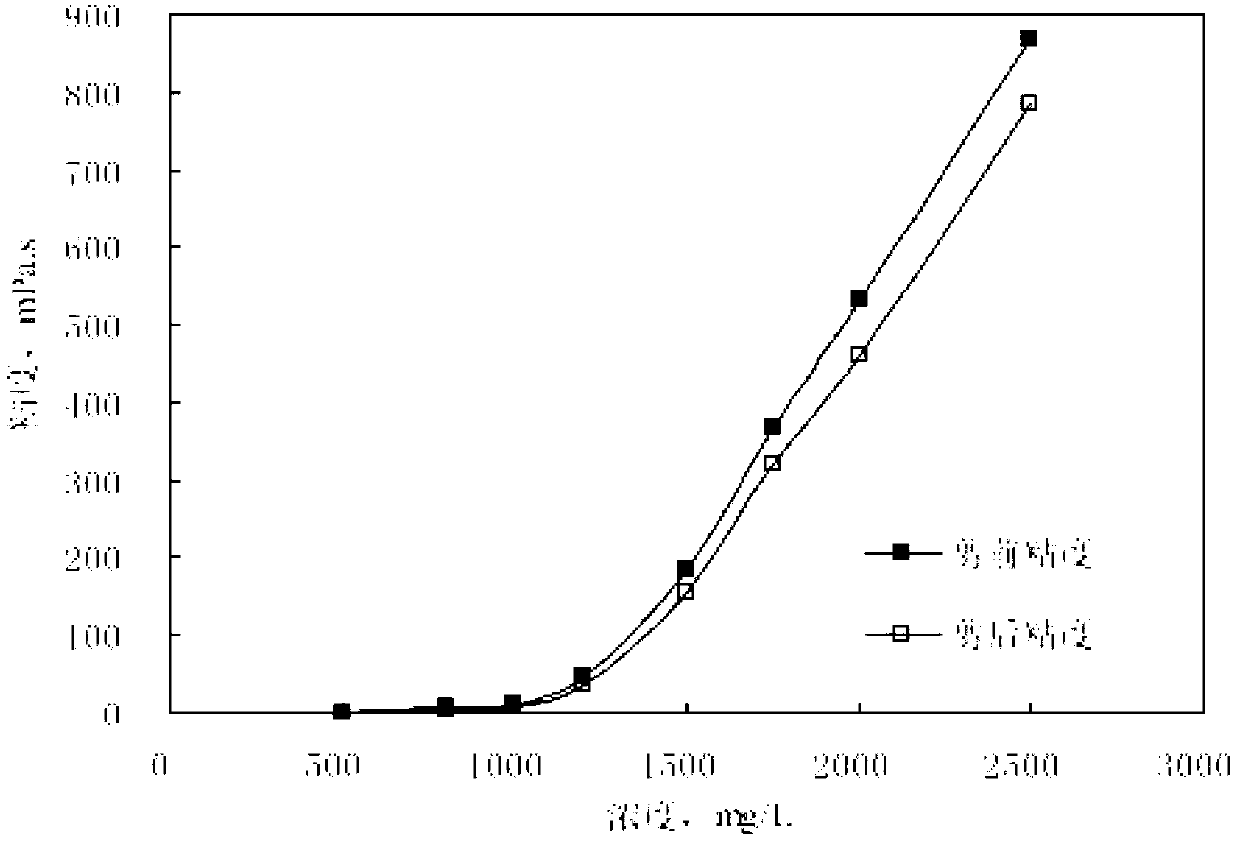

[0046] Weigh 20 grams of acrylamide (AM), 5 grams of acrylic acid (AA), 0.025 grams of functionalized skeleton monomer, 0.2 grams, 0.8 grams, 1.2 grams, and 1.6 grams of dimethylallyl octadecyl ammonium chloride. Add 74 grams of distilled water to the beaker, stir and dissolve evenly, adjust the pH to 5-6 with sodium hydroxide, preheat it in a water bath at 35℃ for 30 minutes, add 0.25 grams each of the cosolvent urea and sodium sulfate , Chain transfer agent 0.05 g sodium methoxide, oxidation-reduction initiator sodium bisulfite and ammonium persulfate 4.6 mg each, react for 8 hours to obtain four jelly polymers.

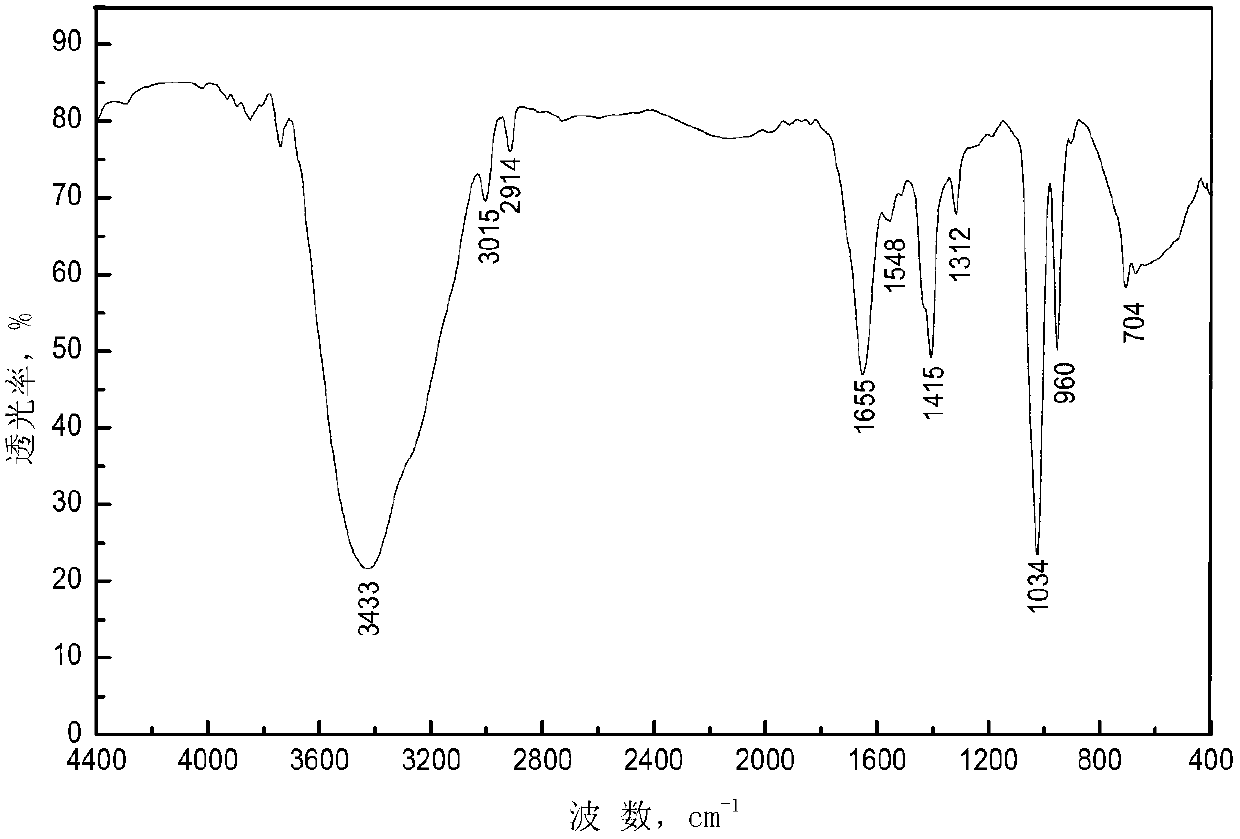

[0047] 2. Infrared spectrum analysis of functionalized skeleton monomer

[0048] The infrared spectrum of the functionalized skeleton monomer can be seen figure 1 .

[0049] figure 1 It shows that the —OH stretching vibration absorption peak of the modified skeleton monomer is 3433, the C—H stretch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com