Natural gas hydrate deposit dynamic triaxial mechanic-acoustic-electrical synchronous test experimental device and method

A hydrate sediment, dynamic triaxial mechanics technology, applied in the application of repetitive force/pulse force to test the strength of materials, the use of sonic/ultrasonic/infrasonic waves to analyze solids, material resistance, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

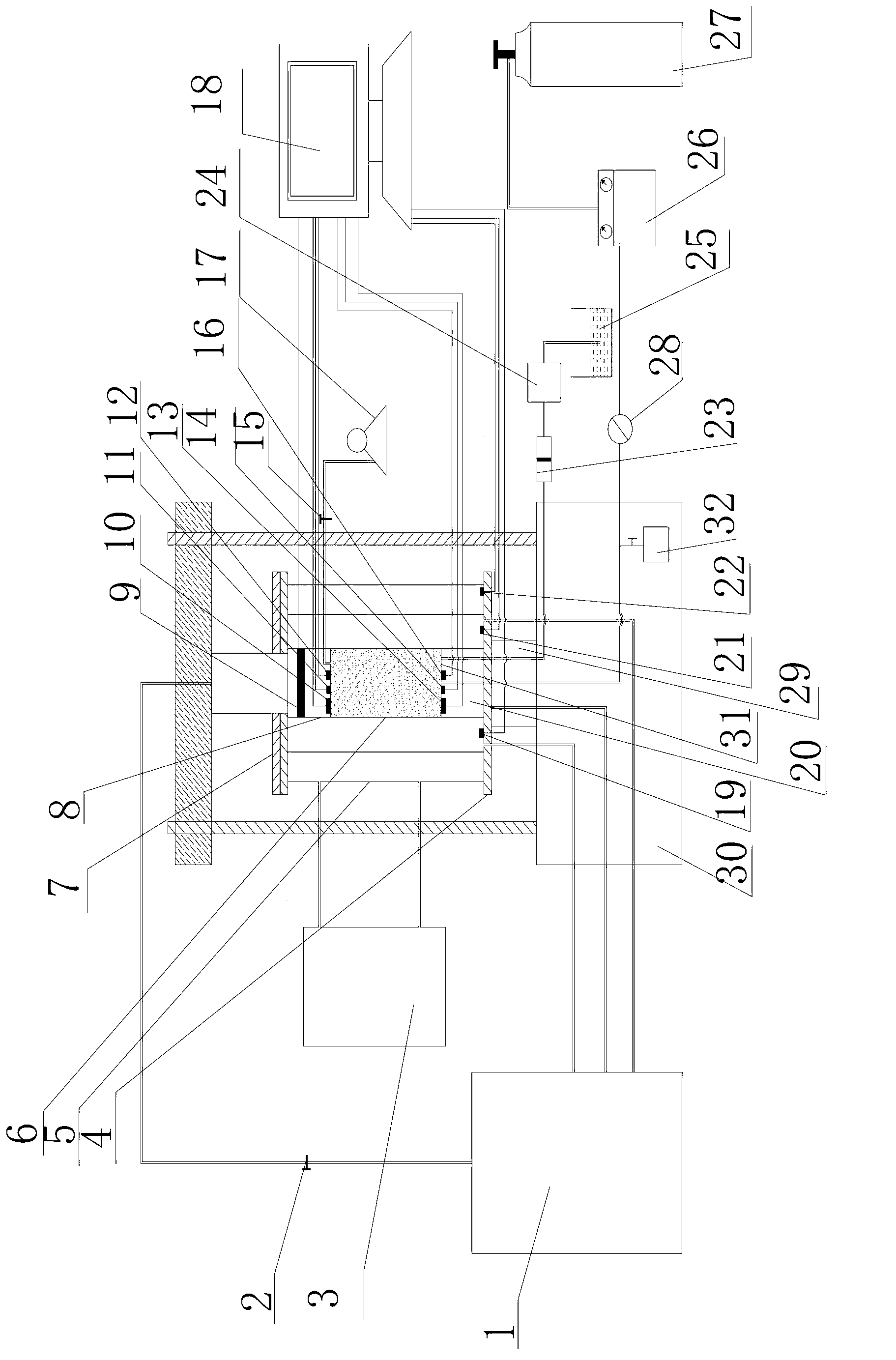

[0044] Such as figure 1 As shown, the experimental device for simultaneous testing of dynamic triaxial mechanics-electricity-acoustics of gas hydrate deposits (that is, the experimental device for simultaneous testing of electrical-acoustic-mechanical properties of gas hydrate deposits) includes: a triaxial pressure chamber, The triaxial pressure chamber is arranged on the base 30, and the triaxial pressure chamber includes an upper end cover 7, a lower end cover 4 and a cylinder 5, and the cylinder 5 is provided with an upper indenter 8 and a lower indenter 20 for loading the sample 6 , the sample 6 is placed between the upper indenter 8 and the lower indenter 20, the lower indenter 20 is fixed on the lower vertical shaft 29, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com