Fruit residue dietary fiber and preparation method thereof

A technology for dietary fiber and pomace, which is applied in the field of food nutrients, can solve the problems of residual, low soluble dietary fiber content, unfavorable safe use, etc., and achieves good swelling properties, reduces environmental pollution and resource waste, and reduces production energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The method for preparing soluble pomace dietary fiber product and insoluble pomace dietary fiber product provided by the present invention, concrete technology can comprise the following steps:

[0058] 1) processing of raw materials: the raw materials of the present invention can be sterilized by a microwave tunnel type sterilizer from the raw material slag produced by the production of concentrated peach juice / peach pulp and apple concentrated juice / apple pulp;

[0059] 2) Leaching: disperse and hydrate the pomace with 4 to 10 times the weight of water, and fully stir in a stirring tank for 10 to 120 minutes at room temperature to remove a small amount of soluble sugar;

[0060] 3) Dynamic superfine pulverization compound enzymolysis: pump the wet pomace containing water into the superfine pulverization-enzymolysis equipment, which mainly consists of colloid mill, superfine pulverizer with different grinding tooth gaps and enzymatic hydrolysis with adjustable temperatu...

Embodiment 1

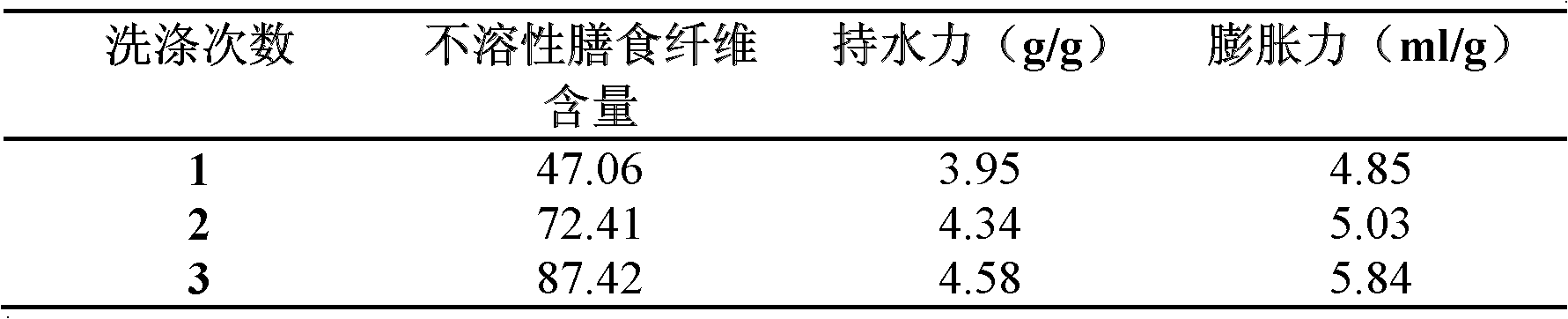

[0065] Take 1 kg of peach residue, after being sterilized by a tunnel-type microwave sterilizer, add 4 kg of water to disperse and hydrate the peach residue for 2 hours; first use a colloid mill to crush the peach residue to 150 μm (60-80 mesh), and then use an ultrafine mill to crush it to 50μm (300 mesh). Use 4mol / l sodium hydroxide to adjust the pH value of the ultrafinely pulverized pomace pulp to 5.0, add 25 IU of cellulase with an enzyme activity of 25IU / ml per kilogram of material to enzymolyze the pomace pulp, and the enzymatic hydrolysis temperature is 50 °C, the enzymatic hydrolysis time is 2 hours, and the pH value is 5.0. After enzymatically deactivating the pomace pulp material (85°C, 2min), centrifuge with a three-legged centrifuge (400 mesh filter cloth), wash with pure water for 3 times, and filter the centrifuged supernatant with a plate and frame , respectively collect the filtrate and the solid precipitate filter cake. The collected solid precipitate filte...

Embodiment 2

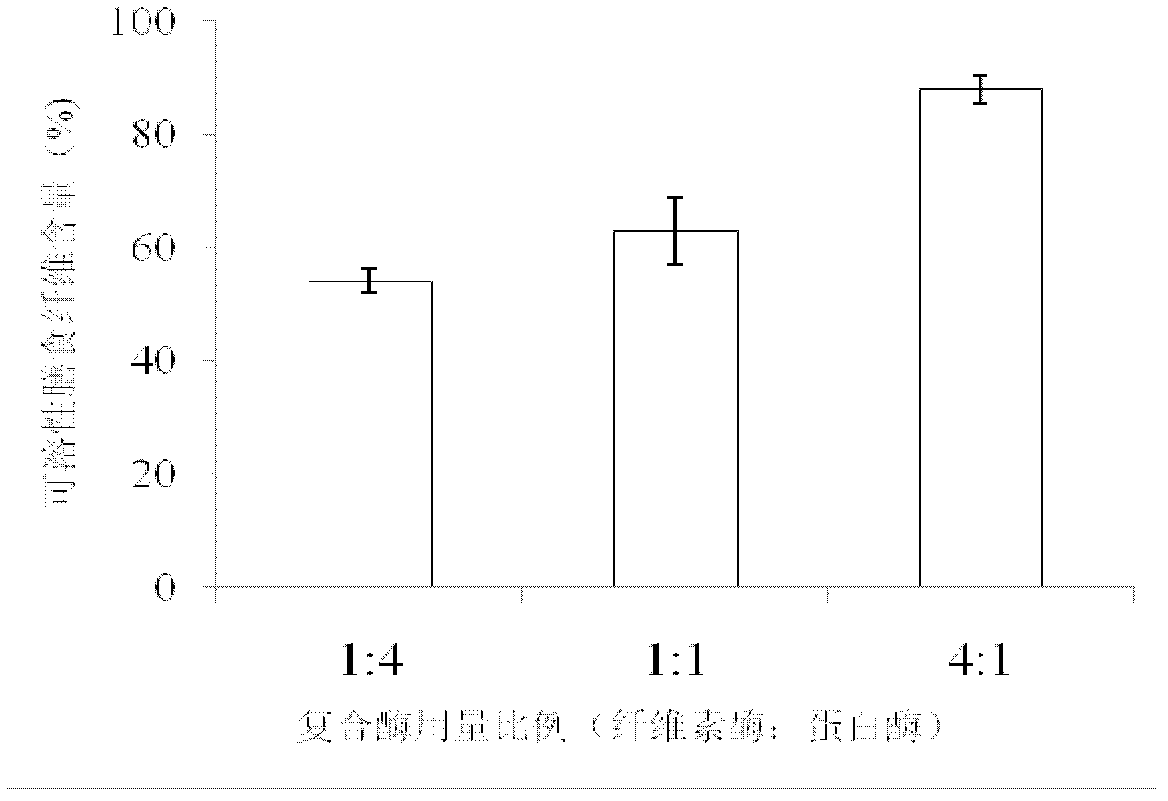

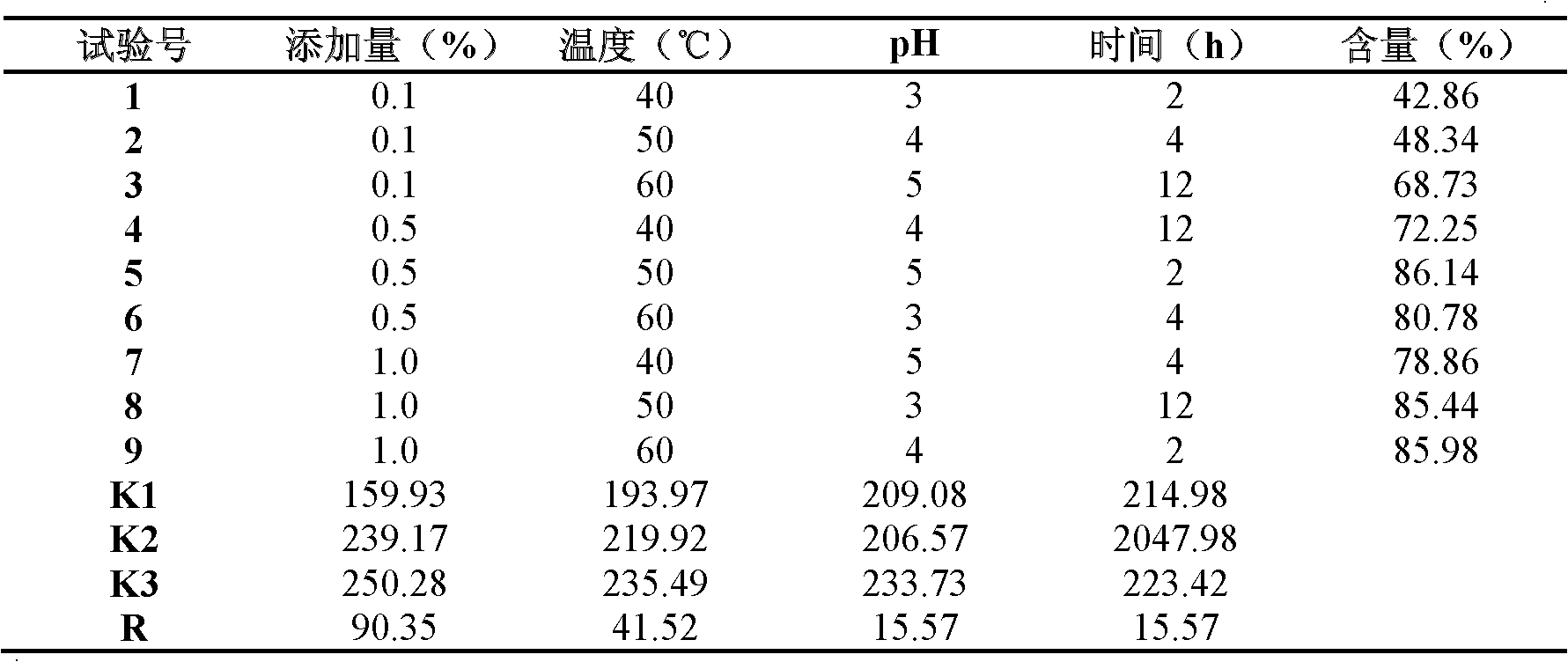

[0071] The filtrate that embodiment 1 is collected is concentrated to the mass percent composition of soluble solids and is 9% (9 ° of Brix), with H 2 o 2 Decolorization is carried out, and the concentrated solution is precipitated with edible alcohol. The consumption of edible alcohol is 4 times the volume of the concentrated solution. After pressure filtration, a colloidal precipitate is obtained, and the alcohol is recovered. The gelatinous precipitate was vacuum dried. Pulverize the colloidal dry matter, sieve and classify, and obtain the soluble pomace dietary fiber product. The effect of cellulase enzymatic hydrolysis conditions on the dietary fiber content of peach residue is shown in Table 2.

[0072] Table 2. Effect of cellulase enzymatic hydrolysis conditions on soluble dietary fiber content

[0073]

[0074] It can be known from Table 2 that under the optimal enzymatic hydrolysis conditions, the content of soluble dietary fiber can exceed 85%.

[0075] The ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com