Production equipment of mixed fruit can and production method thereof

A technology of canned fruit and production equipment, which is applied in the field of food processing, can solve problems such as unreasonable overall design, and achieve the effect of reasonable overall design and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

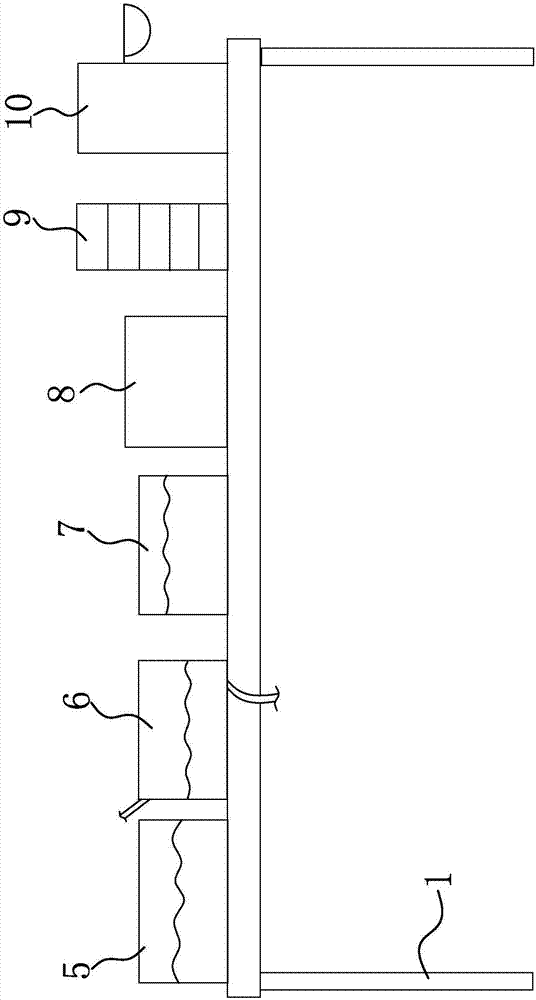

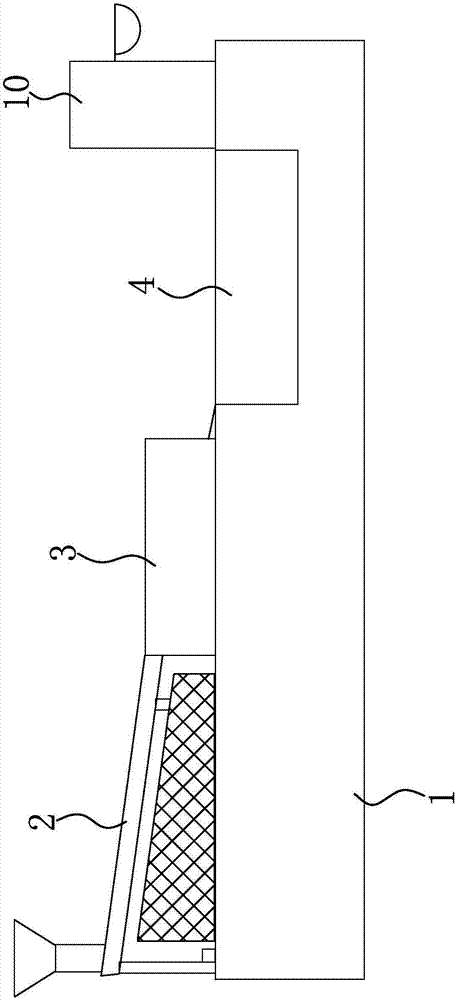

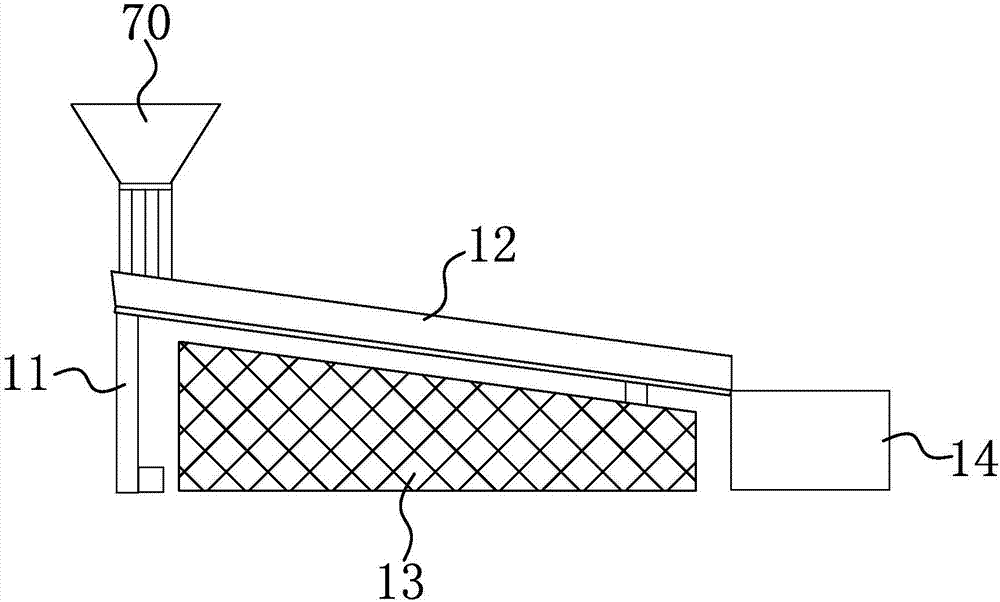

[0044] Such as Figure 1-14 As shown, the production equipment of this mixed fruit can includes a grape processing line and a peach processing line, the grape processing line and the peach processing line are connected with the mixed processing line, and the grape processing line includes a frame 1, which is successively equipped Material selection device 2, a soaking and rinsing device capable of removing impurities on the grape surface 3, a softening device 4 capable of softening grape particles, the peach processing line includes a frame 1, and the frame 1 is sequentially provided with a rubbing device capable of removing the surface hair of the peach Device 5, a rinsing device capable of rinsing the residual brine of juicy peaches 6, a peeling device 7 for peeling juicy peaches, a denucleating and dicing device for depitting and dicing the peeled peaches 8, after dicing The steamer 9 for water-separated steaming of the peaches is carried out, and the mixed processing line ...

Embodiment 2

[0052] Adopt the processing method of the production equipment processing mixed fruit can in embodiment 1, may further comprise the steps:

[0053] A. Peach processing line:

[0054] a1. Select mature peaches, pick out insect-damaged and rotten peaches, add rubbing water to the rubbing device 5, put the peaches into the rubbing device 5 and rub the peaches for 10 minutes, put The peaches are taken out from the rubbing device 5 and put into the flushing device 6, and the floating hairs remaining on the surface of the peaches are rinsed away. The rubbing water in the rubbing device 5 is 1% salt water, Water-insoluble hair rubbing particles are also suspended in the water.

[0055] a2. Put the rinsed peaches into the peeling device 7 for peeling, and then transport them to the de-pitting and dicing device 8 for de-pitting and dicing to obtain diced peaches.

[0056]a3. Put the cut peaches into the steamer 9 and steam them in water for 20-30 minutes. After steaming, take out the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com