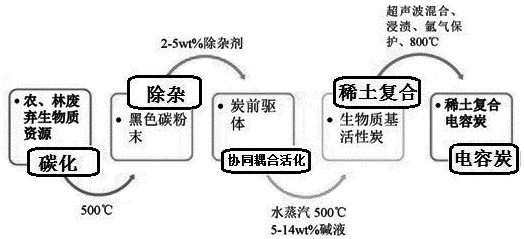

Preparation method of rare earth composite biomass-based capacitor carbon material

A technology of rare earth compounding and biomass raw materials, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, carbon compounds, etc., to achieve the effects of reducing costs, improving mass specific capacitance, and concentrating distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: according to figure 1 The process shown, (1) Carbonization: dry the iron leaf raw material at 120 °C for 24 h, then mechanically pulverize, pass through a 100-mesh sieve, weigh 10 g of biomass powder and place it in a porcelain boat, and place it in a tube furnace Carbonization was carried out in 500 °C, the heating rate was 10 °C / min, argon was used as the protective gas, and the carbonization time was 60 min to obtain black carbon powder.

[0034] (2) Impurity removal: add 100 mL of pre-configured 4% H 2 SO 4 Solution, then add 10g of black carbon powder into the three-necked bottle, soak for 24h, then heat and stir to reflux, the reaction time is 2h, then filter, wash, and dry at 120°C for 24h, you can get carbon precursor.

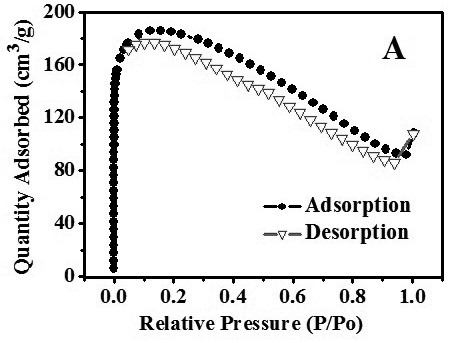

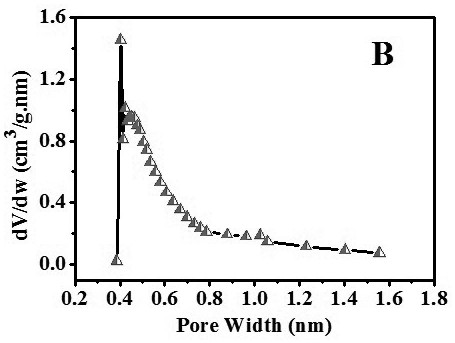

[0035] (3) Synergistic coupling activation: Grind the carbon precursor, pass through a 100-mesh sieve, weigh 10 g of the carbon precursor, put it in a crucible, add a pre-configured 8 wt% sodium hydroxide solution for impregnati...

Embodiment 2

[0041] Embodiment 2: Change the biomass raw material to be rice husk, and the activation temperature is raised to 850 o C, other conditions are as embodiment 1. The specific surface area and pore volume of the prepared carbon material are 651 m 2 / g and 0.43 cm 3 / g. The mass specific capacitance is 167.32 F / g, and the volume specific capacitance is 179.91 F / cm 3 , The capacitance retention rate is 99.92%.

Embodiment 3

[0042] Embodiment 3: change the concentration of activator to be the NaOH solution of 10 wt%, the activation temperature is raised to 850 o C, other conditions are as embodiment 1. The specific surface area and pore volume of the prepared carbon material are 685 m 2 / g and 0.36 cm 3 / g, the specific capacitance value is 176.92 F / g, and the volume specific capacitance is 205.72 F / cm 3 , The capacitance retention rate is 99.70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com