Fabrication method of supercapacitor electrode

A technology for supercapacitors, electrodes, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor fabrication, nanotechnology for materials and surface science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

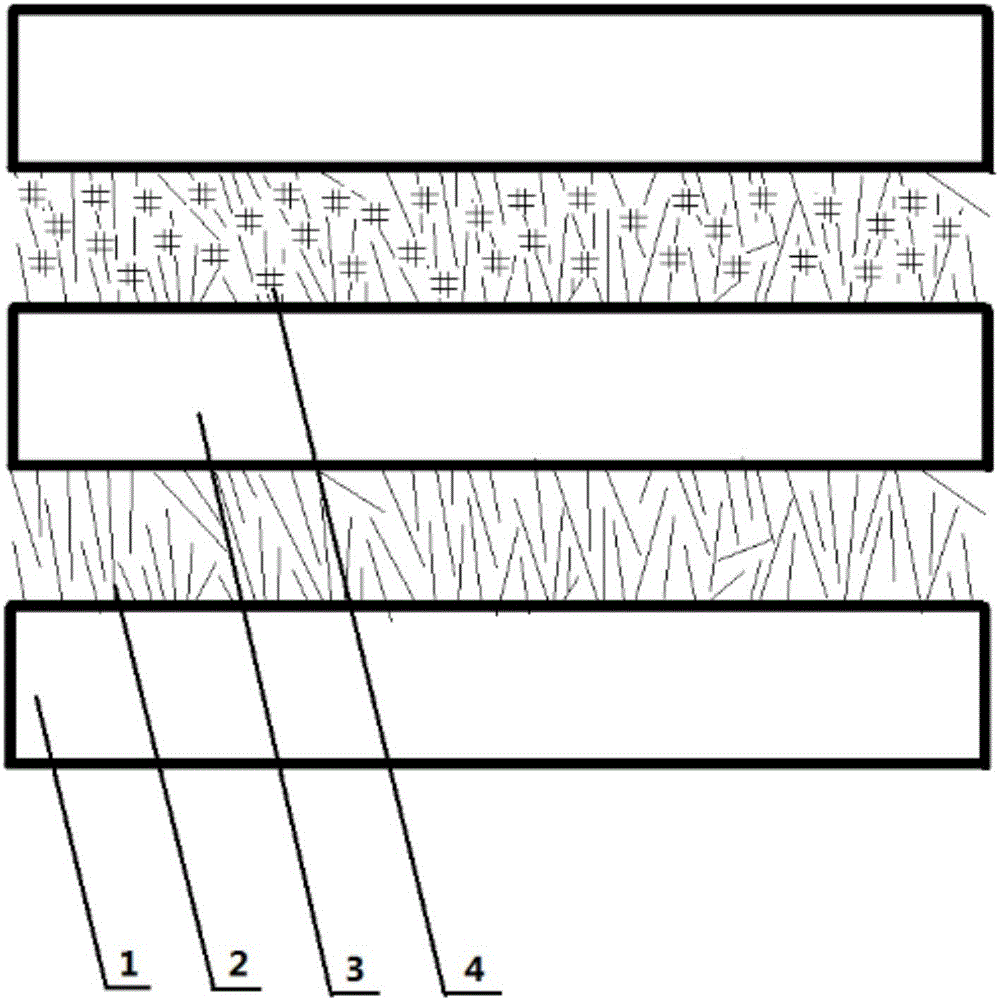

Method used

Image

Examples

Embodiment 1

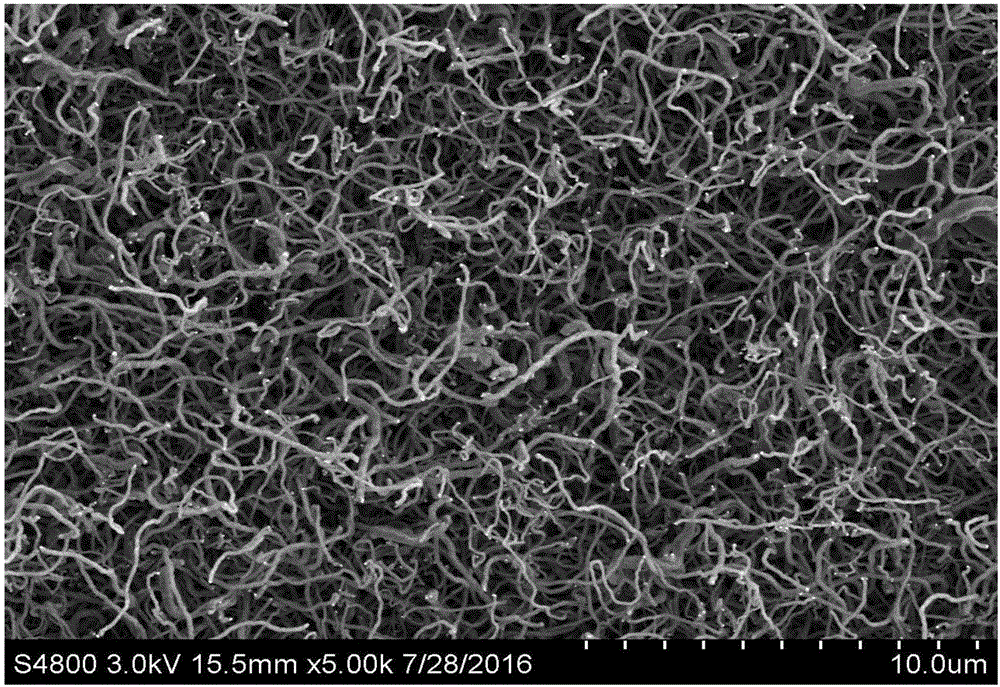

[0028] 1) Cleaning. Based on high-purity titanium (Ti) sheet. For the Ti sheet, first use sandpaper to polish the surface to remove obvious impurities and polish it smoothly, then use a cotton swab to dip in the deionized water solution containing detergent, scrub the base, then rinse it with deionized water solution containing detergent, and then use it in sequence. Deionized water, ethanol, deionized water, acetone ultrasonic cleaning for 10 minutes.

[0029] 2) Prepare the solution. Nickel sulfate hexahydrate (NiSO 4 ·6H 2 O), K12 and MnSO 4 ·H 2 O powdery solid. Prepare 0.5M NiSO 4 ·6H 2 A mixed solution of O and 5mM K12, and 0.5M NiSO 4 ·6H 2 O, 5mM K12 and 0.5M MnSO 4 ·H 2 A mixed solution of O.

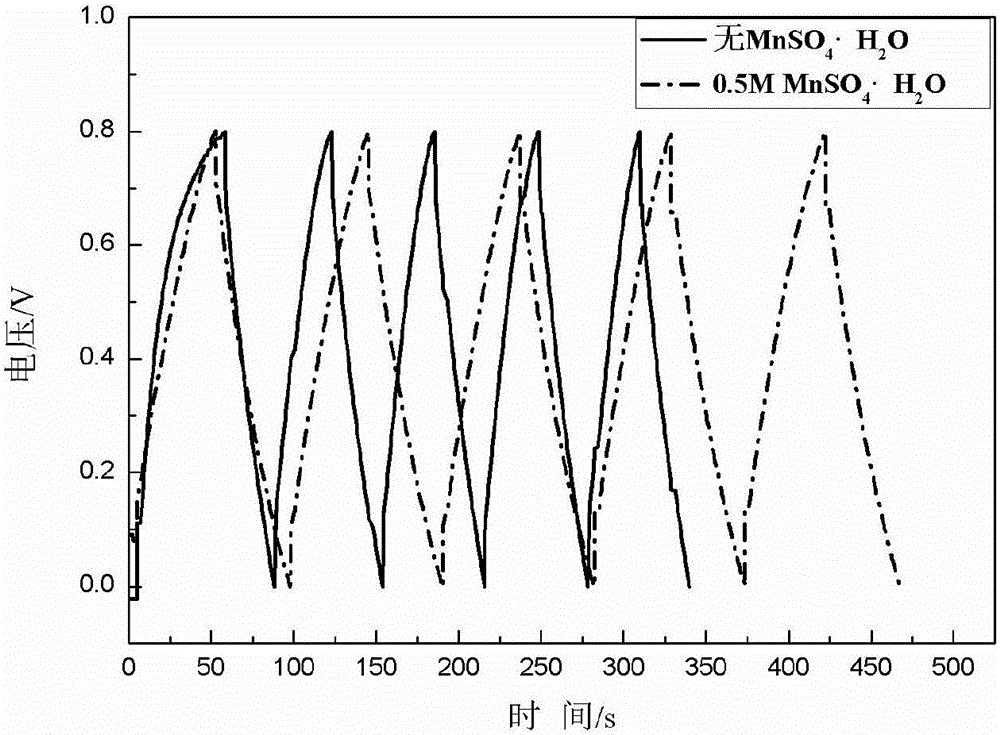

[0030] 2) Preparation of electrodes. Take two groups of 1cm×2cm titanium sheet samples with a thickness of 0.2mm, and then spin-coat the previously prepared 0.5M NiSO 4 ·6H 2 A mixed solution of O and 5mM K12, and 0.5M NiSO 4 ·6H 2 O, 5mM K12 and 0.5M MnSO 4 ...

Embodiment 2

[0035] 1) Cleaning. Based on high-purity Ti flakes. For the Ti sheet, first use sandpaper to polish the surface to remove obvious impurities and polish it smoothly, then use a cotton swab to dip in the deionized water solution containing detergent, scrub the base, then rinse it with deionized water solution containing detergent, and then use it in sequence. Deionized water, ethanol, deionized water, acetone ultrasonic cleaning for 10 minutes.

[0036] 2) Prepare the solution. NiSO 4 ·6H 2 O, K12 and MnCO 3 powdery solid. Prepare 0.5M NiSO 4 ·6H 2 A mixed solution of O and 8mM K12. and 0.5M NiSO 4 ·6H 2 O, 8mM K12 and 2.28g MnCO 3 of the suspension.

[0037] 3) Preparation of electrodes. Take two groups of 1cm×2cm titanium sheet samples with a thickness of 0.2mm, and then spin-coat the previously prepared 0.5M NiSO 4 ·6H 2 A mixed solution of O and 8mM K12, and 0.5M NiSO 4 ·6H 2 O, 8 mM K12 and 2.28 g of MnCO 3 of the suspension. The speed and time are both 2...

Embodiment 3

[0041] 1) Cleaning. Based on high-purity Ti flakes. For the Ti sheet, first use sandpaper to polish the surface to remove obvious impurities and polish it smoothly, then use a cotton swab to dip in the deionized water solution containing detergent, scrub the base, then rinse it with deionized water solution containing detergent, and then use it in sequence. Deionized water, ethanol, deionized water, acetone ultrasonic cleaning for 10 minutes.

[0042] 2) Prepare the solution. NiSO 4 ·6H 2 O, K12 and MnCO 3 powdery solid. Prepare 5mM K12 and 0.5MNiSO 4 ·6H 2 A mixed solution of O. and 5mM K12, 0.5M NiSO 4 ·6H 2 O and 0.57g MnCO 3 of the suspension.

[0043] 3) Preparation of electrodes. Take two groups of five 1cm×2cm titanium sheet samples with a thickness of 0.2mm, and then spin-coat the previously prepared 5mM K12 and 0.5M NiSO on the coater. 4 ·6H 2 Mixed solution of O, and 5mM K12, 0.5MNiSO 4 ·6H 2 O and 0.57g MnCO 3 of the suspension. The speed and time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com