Metal phthalocyanine-mxene composite material, supercapacitor and preparation method thereof

A supercapacitor, metal phthalocyanine technology, applied in the field of electrochemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Copper phthalocyanine (CuPc) nanostructures were prepared by the following process:

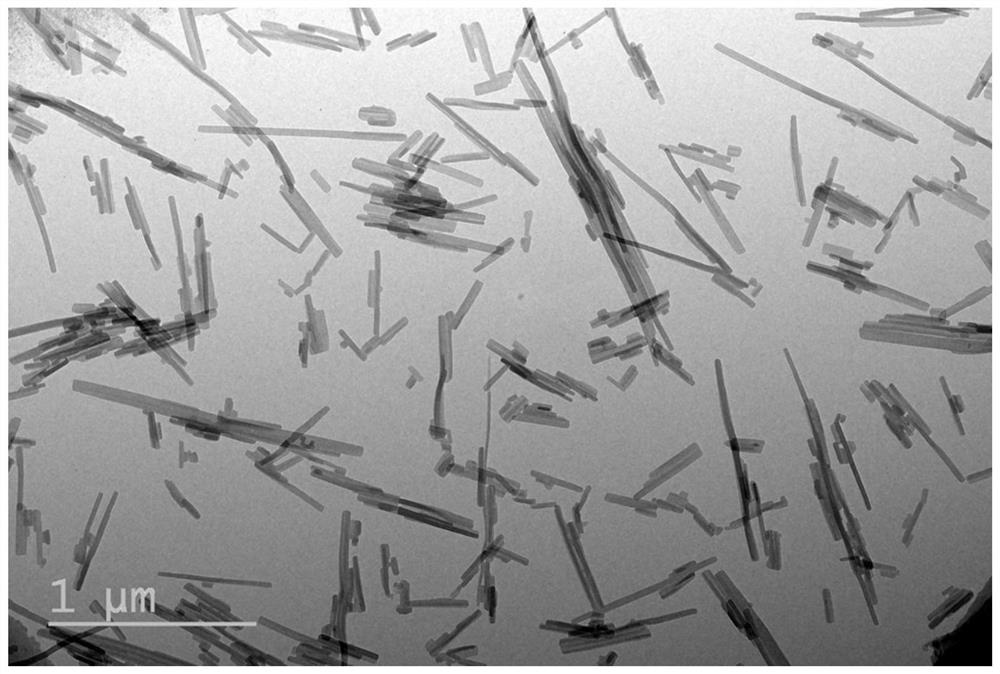

[0067] 2.5 mg CuPc was dissolved in 2.5 mL methanesulfonic acid, and the solution was sonicated. Afterwards, the solution was added dropwise into 200 mL of deionized water at a rate of 2 mL / min with constant stirring to form CuPc nanostructures. Finally, the solid powder was washed with deionized water, ethanol and acetone solutions, respectively, and the filtered product was dried in a vacuum oven at 80 °C. Take a small amount of sample preparation, use TEM to observe the morphology and structure of the material, such as figure 1 As shown, the CuPc nanostructures were found to be nanorods with a length of about 0.2-2 μm and a width of about 50-150 nm.

Embodiment 2

[0069] Peripheral octamethyl nickel phthalocyanine (NiMe 2 Pc) Nanostructures are prepared by the following process:

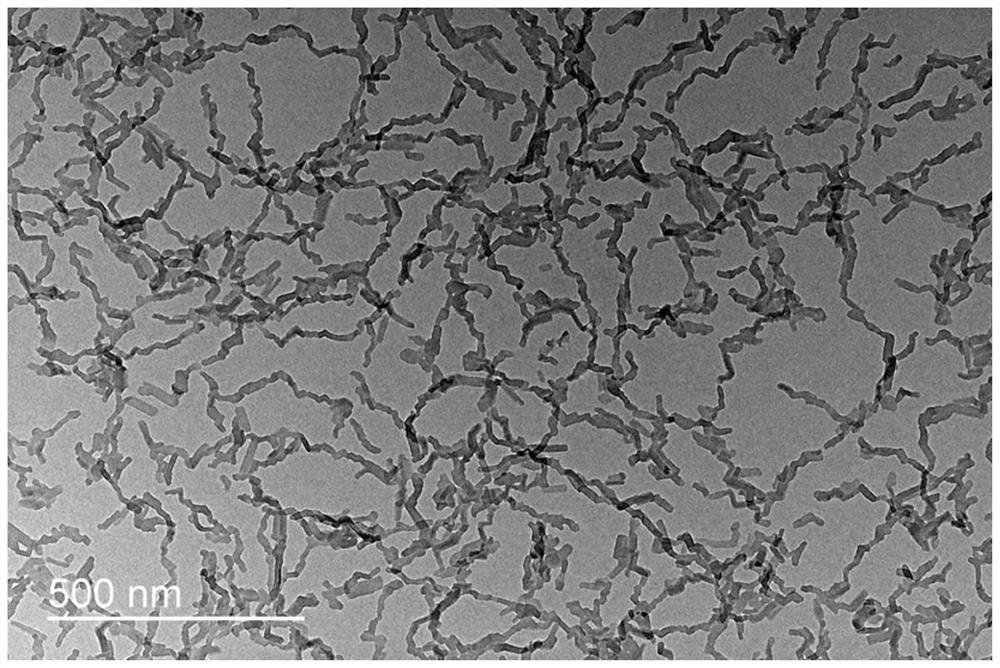

[0070] 10mg NiMe 2 Pc was dissolved in 2 mL of methanesulfonic acid, and the solution was sonicated. Afterwards, the solution was added dropwise into 200 mL of deionized water at a rate of 1 mL / min with constant stirring to form NiMe 2 Pc nanostructures. Finally, the solid powder was washed with deionized water, ethanol and acetone solutions, respectively, and the filtered product was dried in a vacuum oven at 80 °C. Take a small amount of sample preparation, use TEM to observe the morphology and structure of the material, such as figure 2 shown, found NiMe 2 The Pc nanostructure is a nanowire with a length of about 50-500nm and a width of about 20-50nm.

Embodiment 3

[0072] Based on non-peripheral octamethylcopper phthalocyanine (N-CuMe 2 The preparation of the supercapacitor of Pc):

[0073] N-CuMe 2 Pc nanostructures and carbon black were mixed at a weight ratio of 85:10, ground for 15 min, and dispersed in an ethanol solution containing 5 wt% perfluorosulfonic acid. Afterwards, the slurry of the mixture was spread on a carbon paper substrate (2 cm x 1 cm x 0.1 cm) using a doctor blade method. Then, the electrode was dried in a vacuum oven at 80 °C for 10 h to evaporate the solvent. The total effective mass of the electrode is the difference between the mass of the working electrode before and after coating, which is about 1 mg / cm 2 . at 1M H 2 SO 4 In the electrolyte solution, CV studies were performed at a scan rate of 5-100mV / s, and the results were as follows Image 6 Shown in (a); then carry out GCD research under the current density of 0.5~20A / g, the result is as follows Figure 7 (a) shown. When the current density is 0.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com