A modified sepiolite modified electrode and its preparation method and application

A technology for modifying electrodes and sepiolite, applied in the field of electrochemistry, can solve the problem of high impedance of sepiolite clay modified electrodes, and achieve the effects of improving electrochemical performance, fast response speed and enhancing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

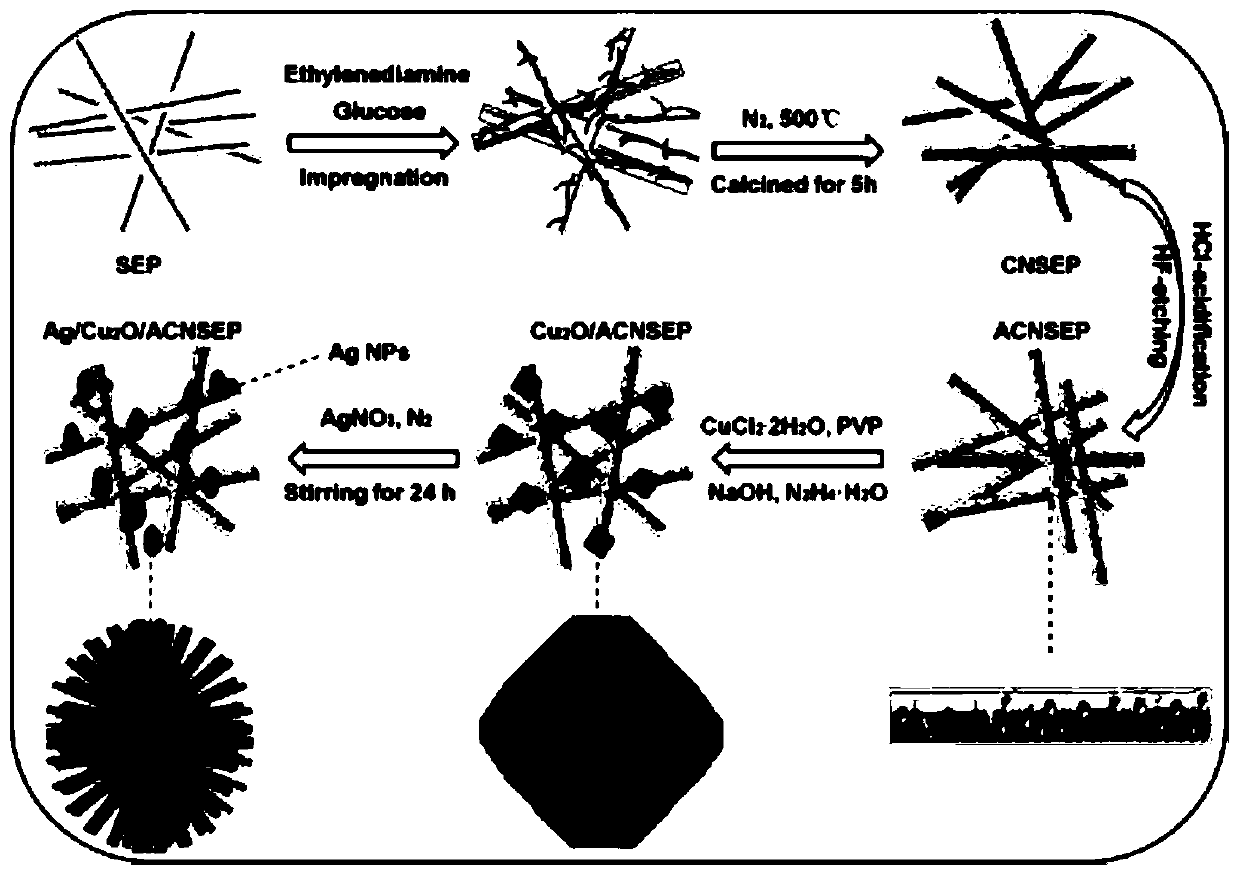

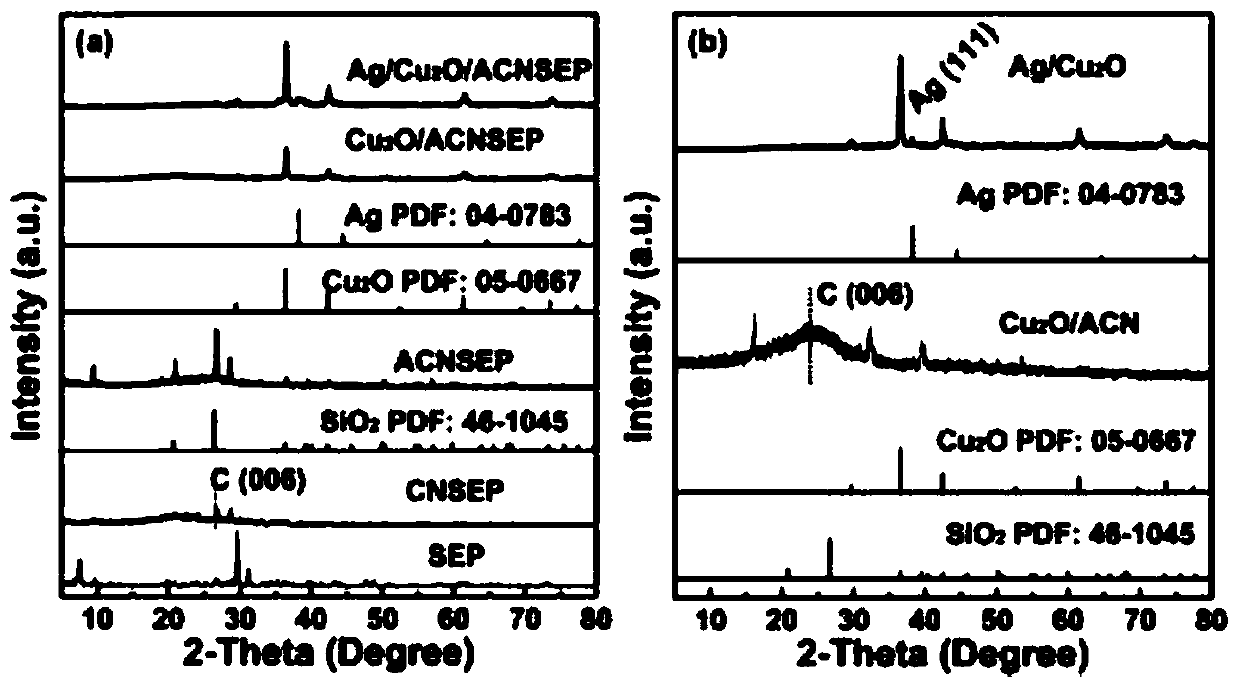

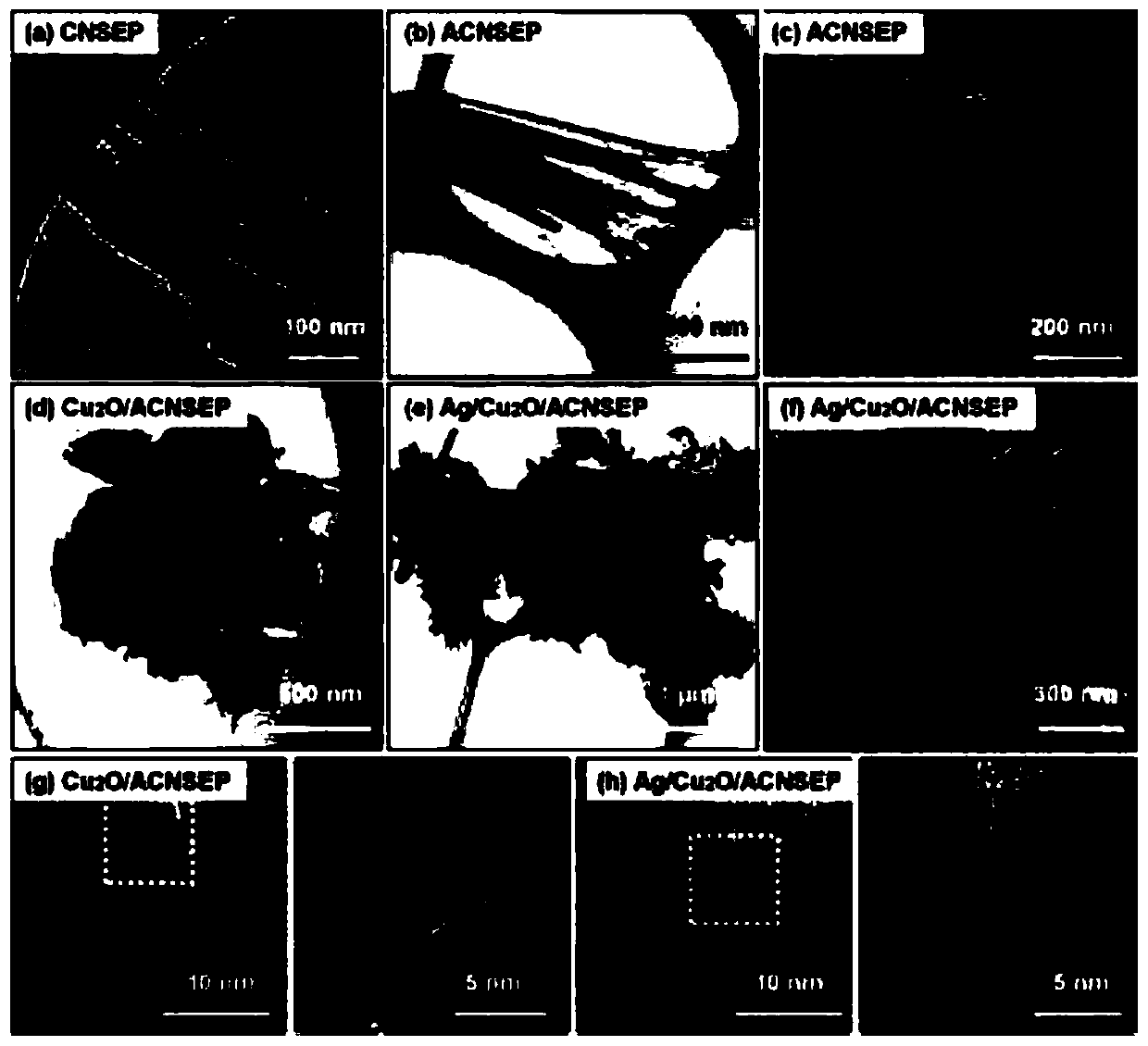

[0035] (1) Add 0.2g of SEP, 0.2g of glucose and 50mL of deionized water into a beaker, and then accurately pipette 0.4g of ethylenediamine, and after stirring for 8 hours, evaporate to dryness in a water bath at 80°C. ℃ under an inert atmosphere for 5 h to obtain nitrogen-doped carbon-modified sepiolite (CNSEP).

[0036] (2) Take 0.2 g of the prepared CNSEP and put it into a beaker, then add 5 mL of HF (mass fraction 40%) to fully react, then vacuum filter, wash and dry. Take 0.1 g of the obtained powder, add 50 mL of 6 mol / L HCl, acidify for 5 h under stirring, and filter and wash with suction to obtain CNSEP (ACNSEP) etched with HF and acidified with concentrated HCl.

[0037] (3) Weigh 0.02g of the ACNSEP complex in a conical flask, then add 0.15g of PVP (polyvinylpyrrolidone) as a surfactant, and 0.1785g of CuCl 2 .2H 2 O was used as the copper source, and then 200 mL of deionized water was pipetted with a graduated cylinder, and stirred continuously for 24 hours to mix ...

Embodiment 2

[0056] (1) Add 0.2g of SEP, 0.2g of glucose and 50mL of deionized water into a beaker, and then accurately pipette 0.5g of ethylenediamine. After fully stirring for 8 hours, evaporate to dryness in a water bath at 80°C. The obtained sample is at 700 ℃ under an inert atmosphere and calcined for 4 hours to obtain nitrogen-doped carbon-modified sepiolite (CNSEP).

[0057] (2) Take 0.2 g of the prepared CNSEP and put it into a beaker, then add 5 mL of HF (mass fraction 40%) to fully react, then vacuum filter, wash and dry. Take 0.1 g of the obtained powder, add 50 mL of 6 mol / L HCl, acidify for 5 h under stirring, and filter and wash with suction to obtain CNSEP (ACNSEP) etched with HF and acidified with concentrated HCl.

[0058] (3) Weigh 0.02g of the ACNSEP compound in a conical flask, then add 0.16g of CTAB (cetyltrimethylammonium bromide) as a surfactant, and 0.2g of CuSO 4 .5H 2 O was used as the copper source, and then 200 mL of deionized water was pipetted with a graduat...

Embodiment 3

[0061](1) Add 0.2g of SEP, 0.2g of glucose and 50mL of deionized water into a beaker, and then accurately pipette 0.45g of ethylenediamine. After fully stirring for 8 hours, evaporate to dryness in a water bath at 80°C. The obtained sample is at 600 ℃ under an inert atmosphere for 5 h to obtain nitrogen-doped carbon-modified sepiolite (CNSEP).

[0062] (2) Take 0.2 g of the prepared CNSEP and put it into a beaker, then add 5 mL of HF (mass fraction 40%) to fully react, then vacuum filter, wash and dry. Then take 0.1 g of the obtained powder, add 50 mL of 6 mol / L HCl, acidify for 5 h under stirring, and filter and wash with suction to obtain CNSEP (ACNSEP) etched with HF and acidified with concentrated HCl.

[0063] (3) Weigh 0.02g of the ACNSEP complex in a conical flask, then add 0.14g of CTAB (cetyltrimethylammonium bromide) as a surfactant, and 0.16g of CuSO 4 .5H 2 O was used as the copper source, and then 200 mL of deionized water was pipetted with a graduated cylinder,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com