Biomass porous carbon material, preparation method thereof and supercapacitor

A technology of porous carbon materials and biomass, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of difficult doping of carbon materials, poor doping effect, and high doping cost. The effect of high purity, excellent electrochemical performance and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] An embodiment of the present invention provides a method for preparing a biomass porous carbon material, comprising the following steps:

[0044] (1) Carbonizing treatment of goldenrod chrysanthemum to obtain crude carbon material.

[0045] In step (1), the golden silk chrysanthemum contains flavonoids, various amino acids, vitamins and trace elements, and carbonization is performed on it. In the obtained crude carbon material, nitrogen, oxygen and trace elements are distributed in situ. Before the carbonization treatment of the golden golden chrysanthemum, the golden golden chrysanthemum is cleaned, or the clean golden golden chrysanthemum is used for the carbonization treatment, so as to exclude the influence of other impurities on the properties of the prepared biomass porous carbon material. Deionized water, ethanol, etc. can be used to wash the golden silk chrysanthemum first, and then dried in a blast drying oven at a drying temperature of 50°C to 80°C. Influence...

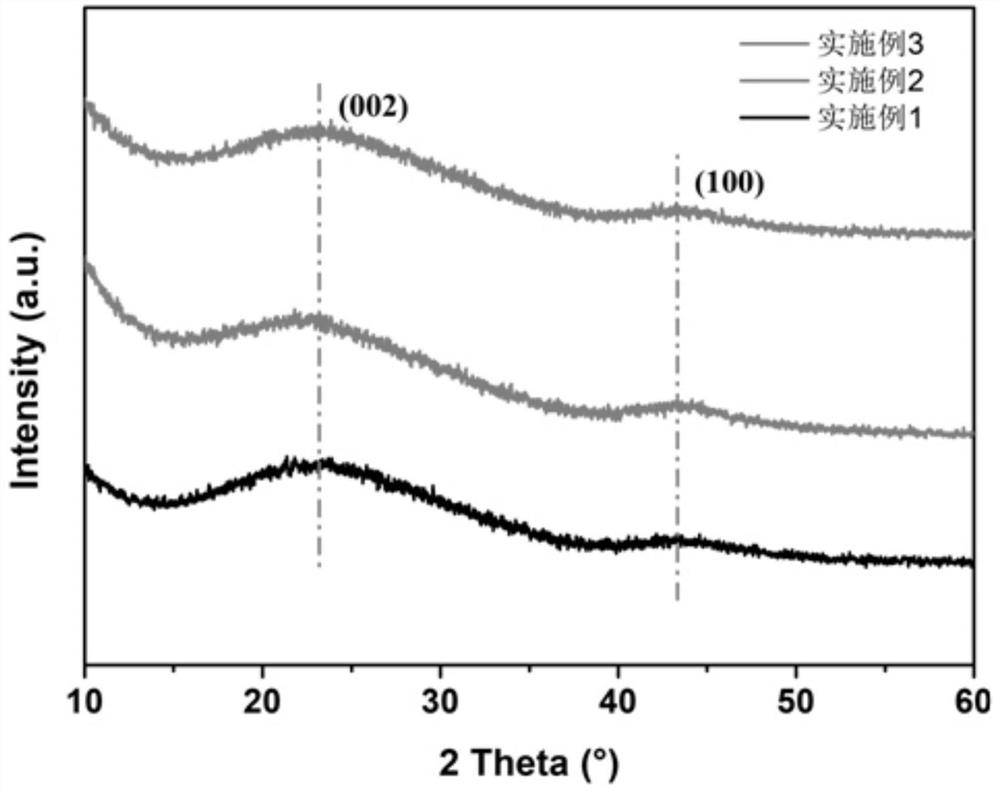

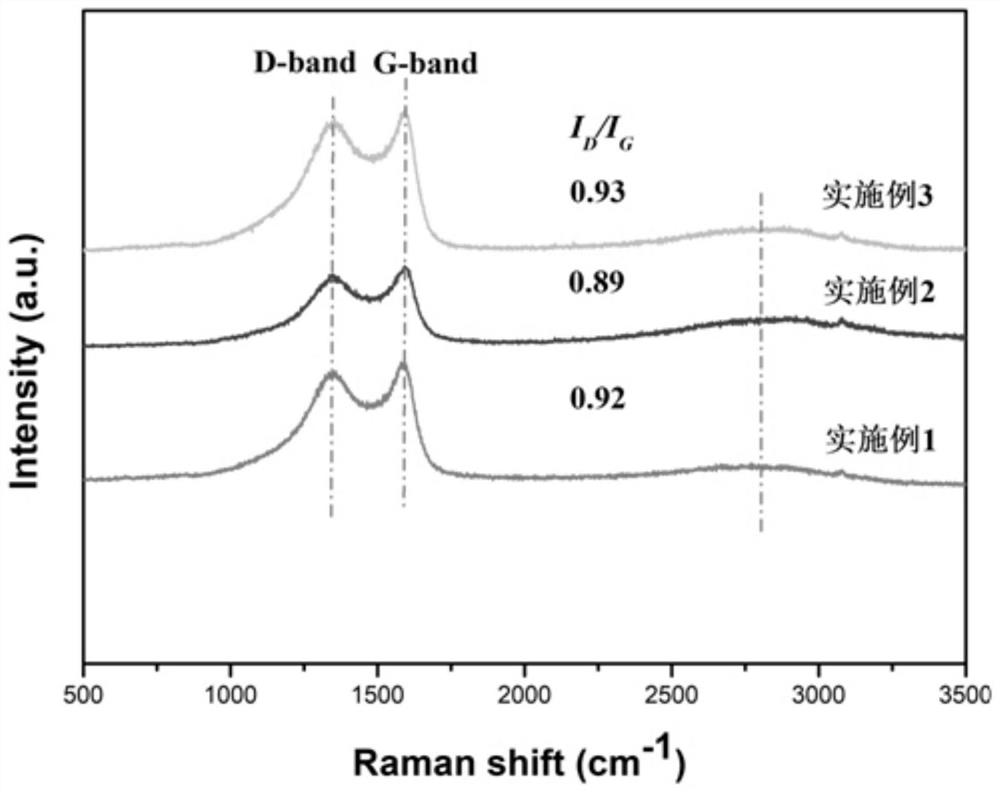

Embodiment 1

[0055] A preparation method of biomass porous carbon material, the steps are as follows:

[0056] (1) The goldenseal chrysanthemum was washed with deionized water, then transferred to a blast drying oven, and dried at 60°C.

[0057] (2) Place the golden silk chrysanthemum obtained in step (1) in a tube furnace, feed nitrogen, and under nitrogen atmosphere, heat up to 800°C at a heating rate of 5°C / min, and keep the temperature at 800°C for 3.0 h, followed by natural cooling to room temperature to obtain a crude carbon material.

[0058] (3) fully grind 0.5g of the crude carbon material obtained in step (2) and 1.5g of potassium hydroxide, so that the crude carbon material and potassium hydroxide are mixed uniformly to obtain a mixture, and then the mixture is transferred to a tube furnace , introduce nitrogen, in a nitrogen atmosphere, heat up to 400 °C at a heating rate of 5 °C / min, keep at 400 °C for 0.5 h, and then heat up to 800 °C at a heating rate of 5 °C / min, and at 80...

Embodiment 2

[0061] A preparation method of biomass porous carbon material, the steps are as follows:

[0062] (1) The goldenseal chrysanthemum was washed with deionized water, then transferred to a blast drying oven, and dried at 80°C.

[0063] (2) placing the golden silk chrysanthemum obtained in step (1) in a tube furnace, feeding nitrogen, under nitrogen atmosphere, heating up to 850°C at a heating rate of 1°C / min, and keeping the temperature at 850°C for 4.0 h, followed by natural cooling to room temperature to obtain a crude carbon material.

[0064] (3) 0.5g of the crude carbon material obtained in step (2) is fully ground with 2.0g of potassium hydroxide, so that the crude carbon material and potassium hydroxide are mixed uniformly to obtain a mixture, and then the mixture is transferred to a tube furnace , introduce nitrogen, in a nitrogen atmosphere, heat up to 400°C at a heating rate of 2°C / min, keep at 400°C for 0.5 h, and then heat up to 800°C at a heating rate of 10°C / min, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com