Preparation method of spirulina-based carbon material for supercapacitor

A technology of supercapacitor and spirulina, applied in the field of preparation of spirulina-based carbon materials, can solve the problems of cumbersome, complicated and time-consuming preparation process, high cost and pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Evenly disperse 0.5 g of spirulina into 100 mL of distilled water, add 0.75 g of potassium oxalate under stirring, and keep stirring continuously for 24 hours.

[0041] (2) The above mixture was centrifuged to collect the precipitate, and freeze-dried for 24 hours.

[0042] (3) Put the product under air at 2°C min -1 The temperature was raised to 200°C at a constant rate for 1h. Then, at N 2 Under the atmosphere, at 2°C min -1The temperature was raised to 600°C at a constant rate and kept at a constant temperature for 120 minutes. Finally, the material was fully washed with hydrochloric acid solution until the pH was 7, then washed with deionized water and ethanol, and dried at 60°C to constant weight to obtain the spirulina carbon material.

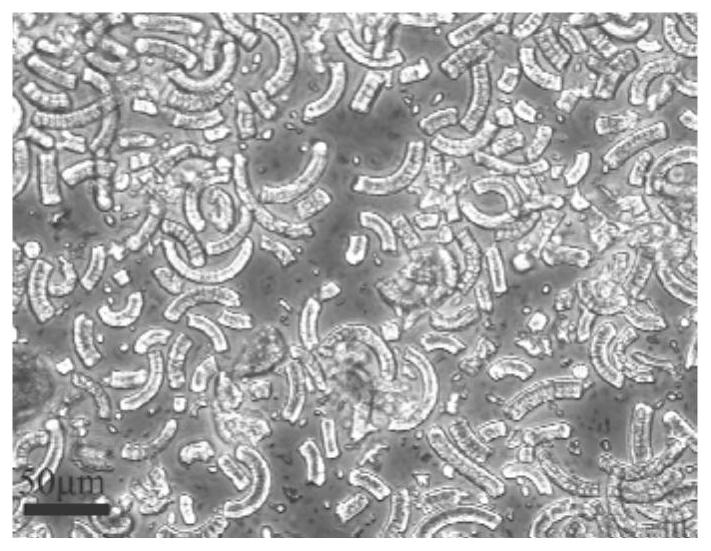

[0043] figure 1 Microscopic image of spirulina. like figure 1 It can be seen that the spirulina presents a curved cylindrical shape and is evenly and widely distributed in the solution.

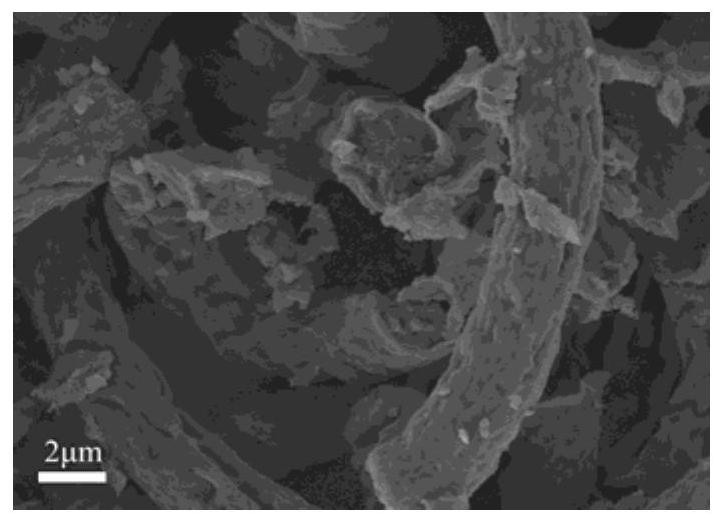

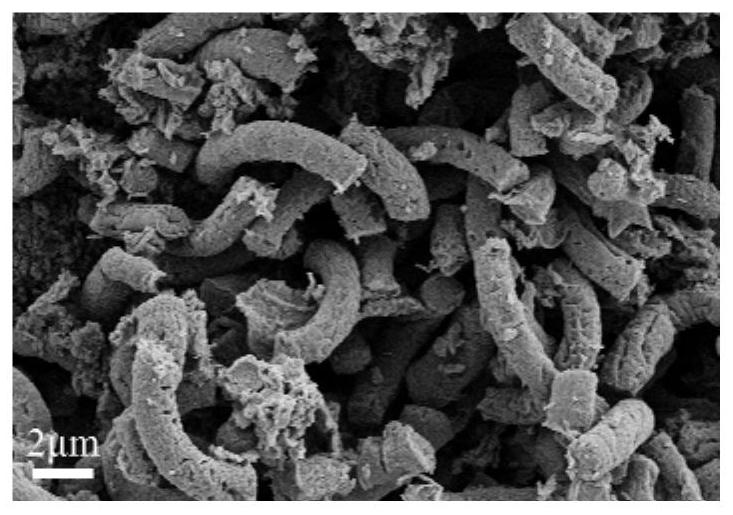

[0044] figure 2 and 3 It is...

Embodiment 2

[0068] With the spirulina carbon material that embodiment 1, comparative example 1 and 2 make respectively as active material, make working electrode, it is carried out electrochemical performance test, comprises the following steps:

[0069] 1) The active material, conductive graphite and binder polytetrafluoroethylene (PTFE) were mixed with an appropriate amount of ethanol at a mass ratio of 8:1:1, and then coated on foamed nickel (1×1cm 2 ) to obtain the working electrode.

[0070] 2) Dry the nickel foam working electrode in an oven at 60°C to constant weight, and then press it into a tablet under a pressure of 10Mpa.

[0071] 3) Prepare working electrode, reference electrode (silver-silver chloride electrode), counter electrode (platinum electrode), salt bridge and 6M KOH electrolyte, and assemble a three-electrode system.

[0072] Figure 14 The galvanostatic charge and discharge curves of the spirulina carbon electrode material prepared for Example 1, Comparative Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com