Preparation method of a high-performance cabbage-like heterostructure electrode material

A heterogeneous structure and electrode material technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve problems such as poor adhesion to current collectors, inability to accurately control synthesis methods, and poor electrical conductivity. , to achieve superior rate performance and improve electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing an electrode material with a high-performance cabbage-like heterostructure, the method comprising;

[0034] 1) Pre-treat the foamed nickel, ultrasonication in deionized water for half an hour, then ultrasonic treatment with alcohol for half an hour, repeat three times, and finally put the foamed nickel into a vacuum drying oven to dry;

[0035]2) Dissolve 2mmol nickel acetate, 4mmo cobalt acetate, 2mmol sodium molybdate, 30mmol ammonium fluoride, and 2g urea into 60ml water, stir for 60 minutes, then transfer the above solution into an 80ml reaction kettle, and keep it warm at 120°C for 12h ; Wait for it to cool down to room temperature naturally, and wash it five times with absolute ethanol and deionized water. Then the prepared samples were dried (at 60° C. for 12 h).

[0036] 3) Next, dissolve 8 mmol of sodium sulfide in 60 ml of deionized water, stir magnetically for 45 min, then transfer the above prepared sample into this solution, then tra...

Embodiment 2

[0044] Different from Example 1, 2) 3mmol nickel acetate, 5mmo cobalt acetate, 3mmol sodium molybdate, 40mmol ammonium fluoride, 5g urea were dissolved in 60ml water, stirred for 60 minutes, then the above solution was transferred to the 80ml reaction kettle, and Keep it warm at 120° C. for 12 hours; wait for it to cool down to room temperature naturally, and wash it five times with absolute ethanol and deionized water. Then the prepared samples were dried (at 60° C. for 12 h).

[0045] 3) Next, dissolve 9 mmol of sodium sulfide in 70 ml of deionized water, stir magnetically for 45 min, then transfer the above prepared sample into this solution, then transfer the above solution into a 90 ml reactor, and keep it at 90°C for 12 h. After it was naturally cooled to room temperature, it was washed three times with absolute ethanol and deionized water. Then the prepared samples were dried (6h at 60°C).

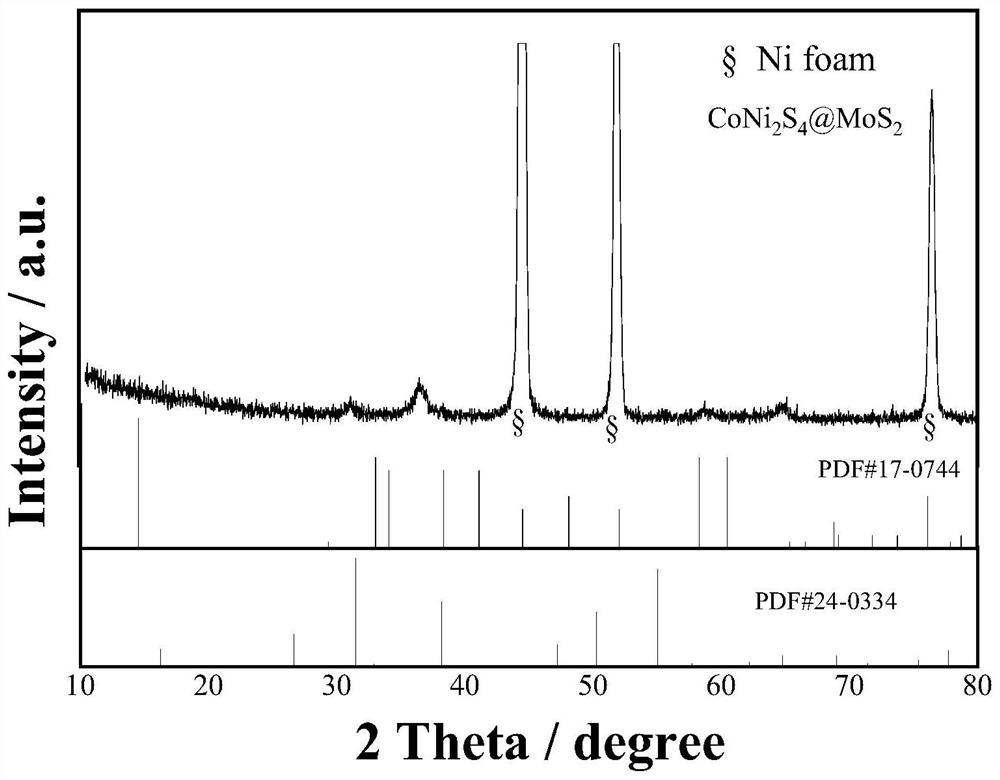

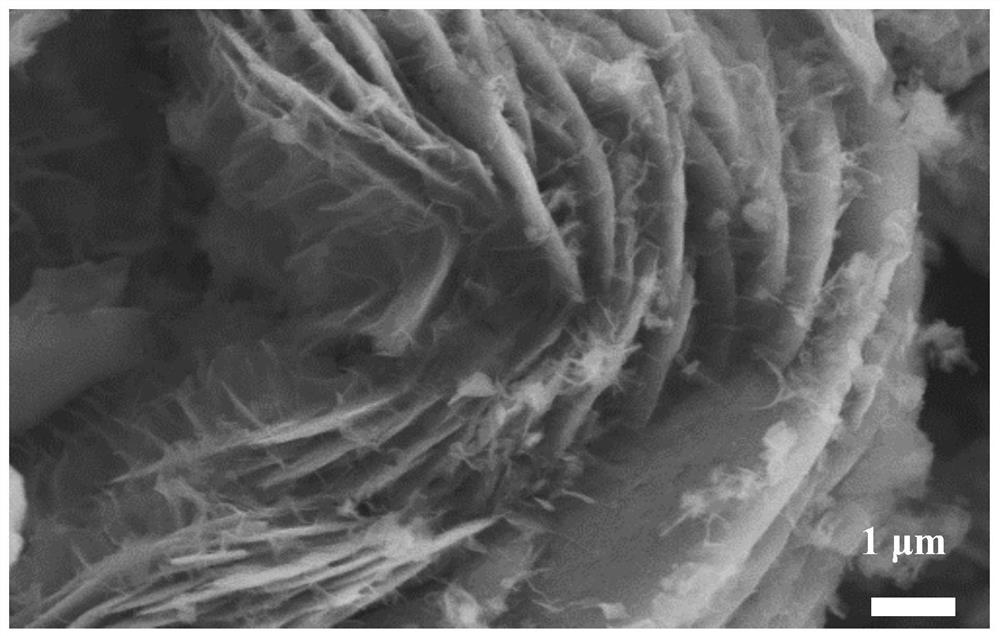

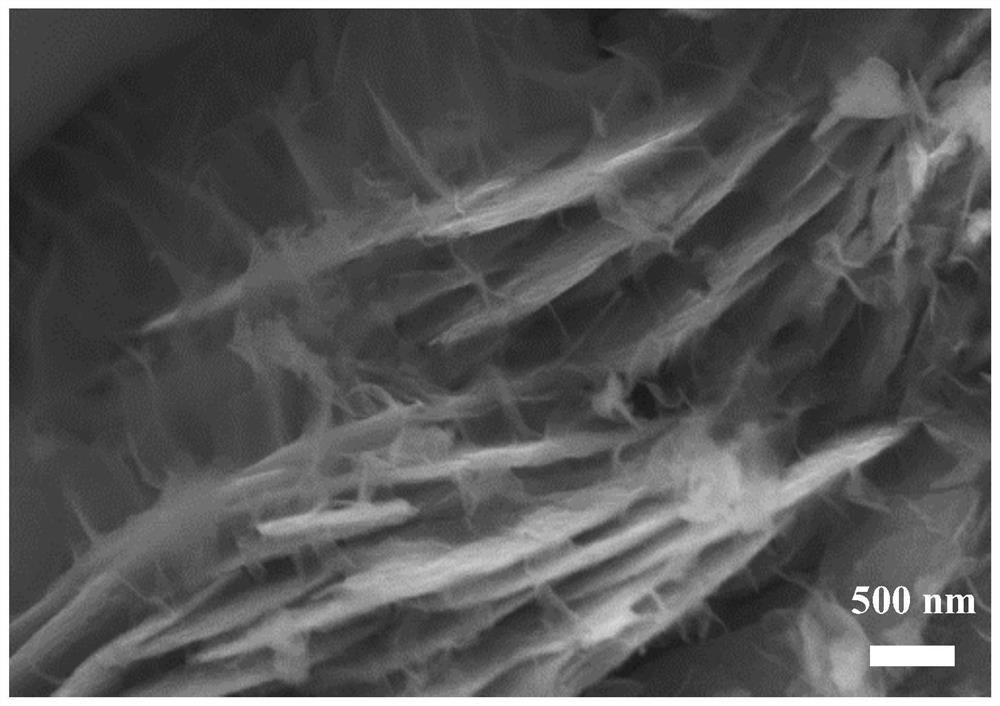

[0046] Carry out X-ray detection to the finished product that embodiment 1 ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com