Preparation method of nitrogen-doped porous biochar and method for preparing electrode material

A biological carbon and nitrogen doping technology, applied in chemical instruments and methods, hybrid capacitor electrodes, carbon compounds, etc., can solve the problems of complex preparation process and high cost, achieve simple preparation process, high energy density, and improve buffer storage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing nitrogen-doped porous biochar, comprising the following steps:

[0025] (1) Raw material pretreatment: The terrestrial biomass and algae biomass are mixed and pretreated according to the mass ratio of 1:0.2~1:5. Both the terrestrial biomass and the algal biomass are in the form of dry powder. The terrestrial biomass includes reeds and reed flowers. , bagasse, taro stalk, catkins, algal biomass including kelp, Enteromorpha, Sargassum, laver, hijiki and other large seaweeds and chlorella, Scenedesmus obliques, spirulina, For microalgae such as cyanobacteria, the mixing methods include dry mixing method and hydrothermal method; the dry mixing method is to put a certain proportion of terrestrial biomass and algal biomass into a mortar or ball mill for full grinding, so that the terrestrial biomass and algal biomass fully contact , to obtain pretreated raw materials; the hydrothermal method is to put a certain proportion of the mixture of terrestrial b...

Embodiment 1

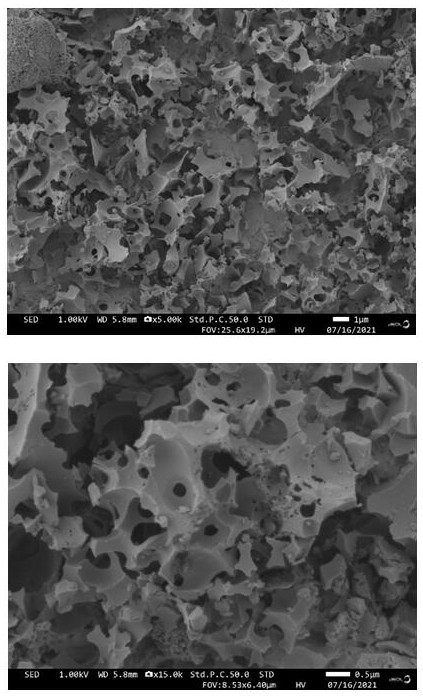

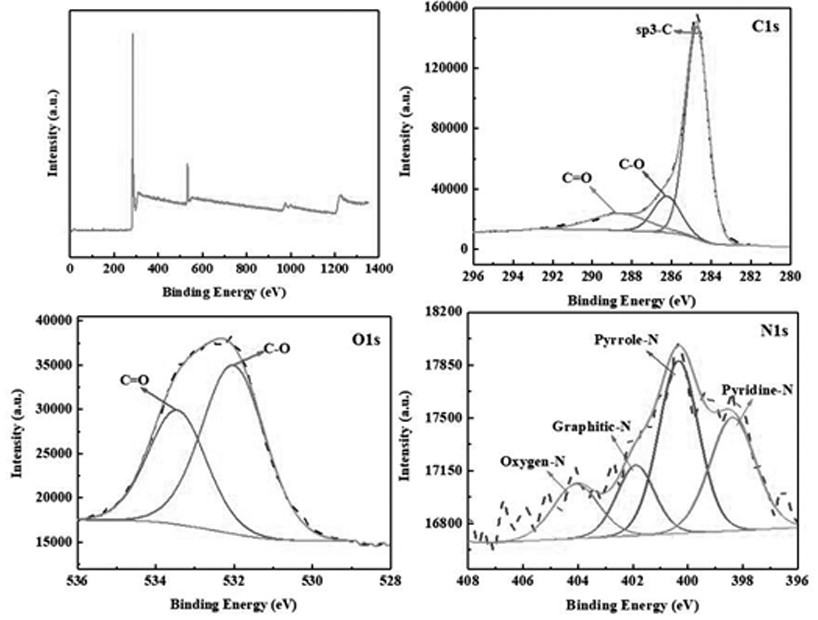

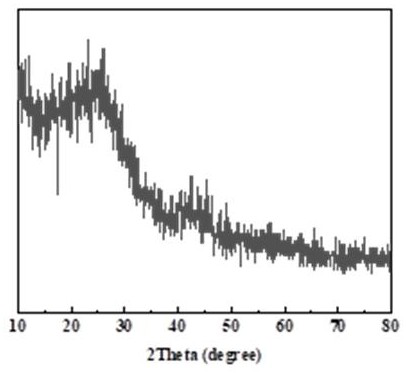

[0031] Preparation of nitrogen-doped porous biochar:

[0032] (1) Raw material pretreatment: Grind and mix 1g of bagasse and 0.5g of Scenedesmus obliquus evenly;

[0033] (2) Add activator: Grind the pretreated raw material and potassium hydroxide according to the mass ratio of 1:1 to mix them evenly;

[0034] (3) Carbonization and pickling: put the mixture in step (2) in a tube furnace, raise the temperature to 700°C at a rate of 3°C / min in an argon atmosphere, keep it warm for 1h, and then cool it naturally to room temperature , to obtain nitrogen-doped porous carbon; then put the obtained nitrogen-doped porous carbon into 200ml of 1mol / L hydrochloric acid solution, stir at room temperature for 24h; finally, wash the nitrogen-doped porous carbon with deionized water Wash until neutral, and dry in an oven at 105° C. for 24 hours to obtain a nitrogen-containing porous carbon material for supercapacitors.

[0035] Preparation of electrode materials in the three-electrode test...

Embodiment 2

[0039] Preparation of nitrogen-doped porous biochar:

[0040] (1) Raw material pretreatment: Grind and mix 1g reed powder and 1.2g chlorella evenly;

[0041] (2) Add activator: Grind the pretreated raw material and potassium bicarbonate according to the mass ratio of 1:4 to mix them evenly;

[0042] (3) Carbonization and pickling: put the mixture in step (2) in a tube furnace, raise the temperature to 800°C at a rate of 5°C / min under an argon atmosphere, keep it warm for 2 hours, and then cool to room temperature; Put the sample obtained above into 150ml of 2mol / L hydrochloric acid solution, stir at room temperature for 24h; finally, wash the acid-washed material to neutrality, and dry it in an oven at 105°C for 24h to obtain a nitrogen-containing porous carbon material.

[0043] Preparation of electrode materials in the three-electrode test system:

[0044] Put 0.003g of nitrogen-doped porous biochar into a centrifuge tube, add 1ml of absolute ethanol, put it into the ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com