Modification method for preparing polyvinyl chloride surface with high cohesive force

A polyvinyl chloride, high-adhesive technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of high thermal effect, lack of photochemical reaction effect, etc., achieve stable performance, fast preparation speed, and increase the effect of roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

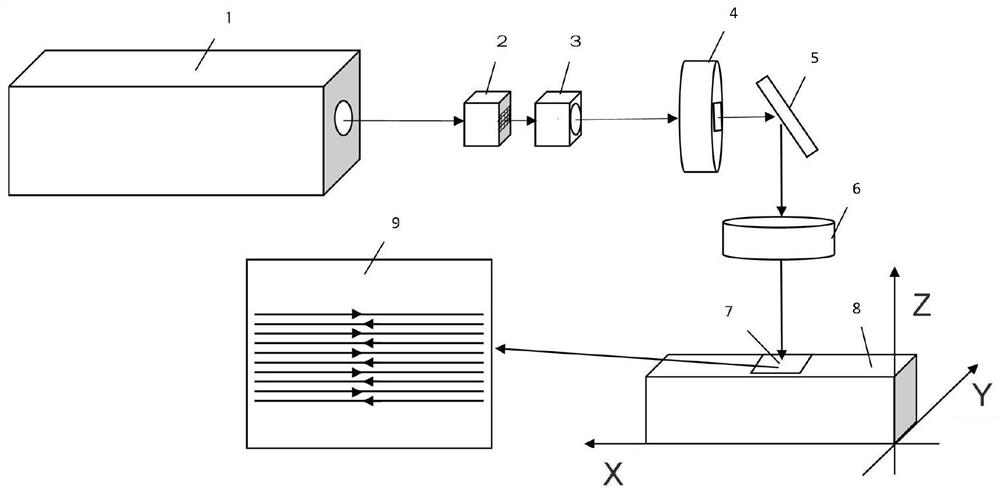

Method used

Image

Examples

Embodiment 1

[0032] After the ArF laser is reflected by a uniform beam, there will be a picture with a size of 1.2×1.2=1.44mm 2 The square thermal paper is placed on the three-dimensional mobile platform, after adjusting the three-dimensional mobile platform, and the position of the 8 times objective lens, and 1.44mm 2 A square-like light spot, and record the coordinates of the three-dimensional mobile platform as P at this time. Use ArF excimer laser to process the PVC surface at a certain speed, the beam defocus is 3mm, the laser frequency is 3hz, the moving speed of the three-dimensional moving table is 0.1mm / s, and the irradiation area of the spot is 1.5mm 2 , set different laser voltages 17, 18, 19, 20, 21, 22, 23KV changes, the sample number is 1.1-1.7, the surface roughness obtained with a 3D profiler, the roughness began to show a decreasing trend, and the laser voltage was 19KV (optical density 27.47mJ / mm 2 ) Later, the roughness tends to increase gradually, and a certain degr...

Embodiment 2

[0034] After the ArF laser is reflected by a uniform beam, there will be a picture with a size of 1.2×1.2=1.44mm 2 The square thermal paper is placed on the three-dimensional mobile platform, after adjusting the three-dimensional mobile platform, and the position of the 8 times objective lens, and 1.44mm 2 A square-like light spot, and record the coordinates of the three-dimensional mobile platform as P at this time. Use ArF excimer laser to treat the PVC surface with a certain power, the beam defocus is 3mm, the laser frequency is 3hz, the laser energy is 23kv (the energy in the cavity is 49.06mJ, the measured energy is 12.14mJ, and the energy density is 8.10mJ / mm 2 ), the spot irradiation area is 1.5mm2, the laser scanning speed changes from 0.02, 0.04, 0.06, 0.08, 0.10, 0.12, 0.12, 0.14, 0.16, 0.18, 0.20mm / s, the sample number is 2.1-2.10, with 3D The surface roughness obtained by the profiler is 1.43μm when the moving speed is 0.20mm / s, and the roughness of the original s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com