Composite electrode and preparation method and application

A composite electrode and electroplating solution technology, used in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of reduced electrode performance, complex process, complicated experimental steps, etc., to achieve enhanced mechanical stability, high quality ratio Capacitance, the effect of facilitating ion transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

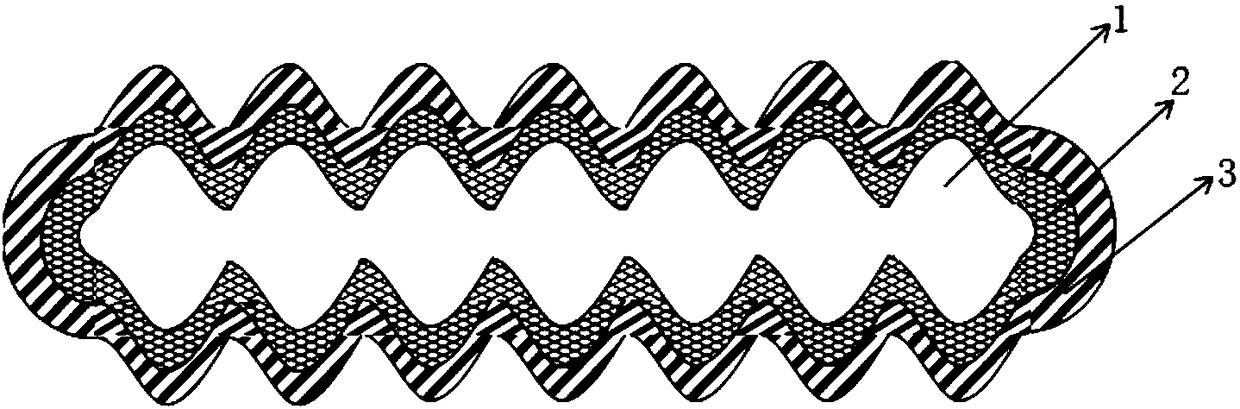

[0035] A preparation method of a composite electrode, specifically comprising the following steps:

[0036] 1) Preparation of the substrate: cleaning the substrate to remove the oxide layer and oil on the surface;

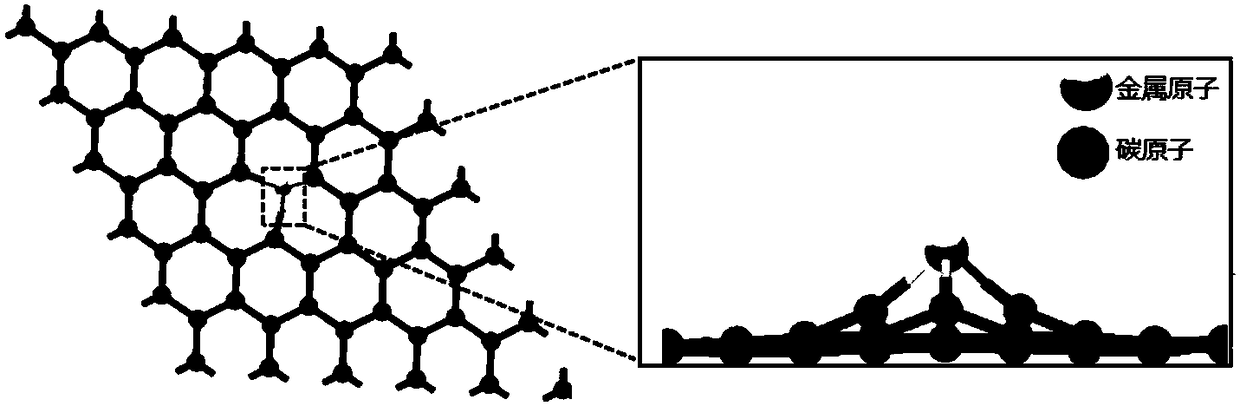

[0037] 2) Preparation of solution: prepare additive solution containing carbon-based materials, and its concentration range is 3-7 mg·mL -1 ;

[0038] Prepare an electroplating solution containing transition metal oxides, the concentration of transition metal ions in the electroplating solution ranges from 3 to 5M;

[0039] 3) electroplating carbon layer: on the substrate after cleaning, adopt the additive solution in step 2) to electroplate the carbon layer;

[0040] 4) electroplating transition metal oxide layer: on the substrate after electroplating the carbon layer, continue to use the electroplating solution in step 2) to electroplate the transition metal oxide layer;

[0041] 5) Cleaning and drying: after electroplating, rinse repeatedly with deionized wat...

Embodiment 1

[0050] A preparation method of a composite electrode, specifically comprising the following steps:

[0051] 1) Preparation of the substrate: first take the foamed nickel, cut it into a sample of 1cm×2cm, soak it in hydrochloric acid (6M), acetone, ethanol in sequence and ultrasonically clean it for 10min to remove the surface oxide layer and oil, and then put it into a nitrogen glove box medium dry for later use;

[0052] 2) Preparation of the solution: prepare an additive solution containing carbon-based materials, containing 3 mg·ml -1 GO, 2mg·ml -1 AC and 0.1M lithium perchlorate trihydrate (LiClO 4 ·3H 2 O) mixing the aqueous solution so that the total concentration of the carbon-based material in the solution is 4 mg·ml -1 , ultrasonic mixing and magnetic stirring for 1 h each;

[0053] Prepare a plating solution containing transition metal ions, including 1M Co(NO 3 ) 2 ·6H 2 O, 2M MnCl 2 4H 2 A mixed aqueous solution of O and 1M sodium chloride (NaCl), so that...

Embodiment 2

[0062] A preparation method of a composite electrode, specifically comprising the following steps:

[0063] 1) Preparation of the substrate: first take foamed nickel, cut it into a sample of 1cm×2cm, soak it in hydrochloric acid (6M), acetone, ethanol and ultrasonically clean it for 10min to remove the surface oxide layer and oil, and then put it in a nitrogen glove box Dry and reserve;

[0064] 2) Preparation of the solution: prepare an additive solution containing carbon-based materials, containing 3 mg·ml -1 GO, 2mg·ml -1 AC and 0.1M LiClO 4 ·3H 2 O Mix the aqueous solution so that the total concentration of carbon-based materials in the solution is 5 mg·ml -1 , ultrasonic mixing and magnetic stirring for 1 h each;

[0065] Prepare a transition metal oxide-containing plating solution containing 1M Co(NO 3 ) 2 ·6H 2 O, 2M MnCl 2 4H 2 O, 2MNiCl 2 ·6H 2 A mixed aqueous solution of O and 1M NaCl, so that the total concentration of transition metal ions in the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com