Preparation method for graphene membrane electrode material of supercapacitor

A supercapacitor and graphene film technology, applied in the field of preparation, can solve the problems of increasing the quality and volume of supercapacitors, low bulk density, general performance, etc., and achieve the effects of improving cycle stability, low reaction temperature, and improving capacitance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0023] The preparation of implementation case 1 graphene film electrode material

[0024] Preparation of graphene oxide film: According to the improved Hummers method, graphite was used as raw material to prepare a graphene oxide aqueous solution with a concentration of 5 mg / mL. Take 2 mL of a 5 mg / mL graphene oxide aqueous solution in a polytetrafluoroethylene cover, put it in a vacuum oven at 30°C, and dry it to obtain a graphene oxide film.

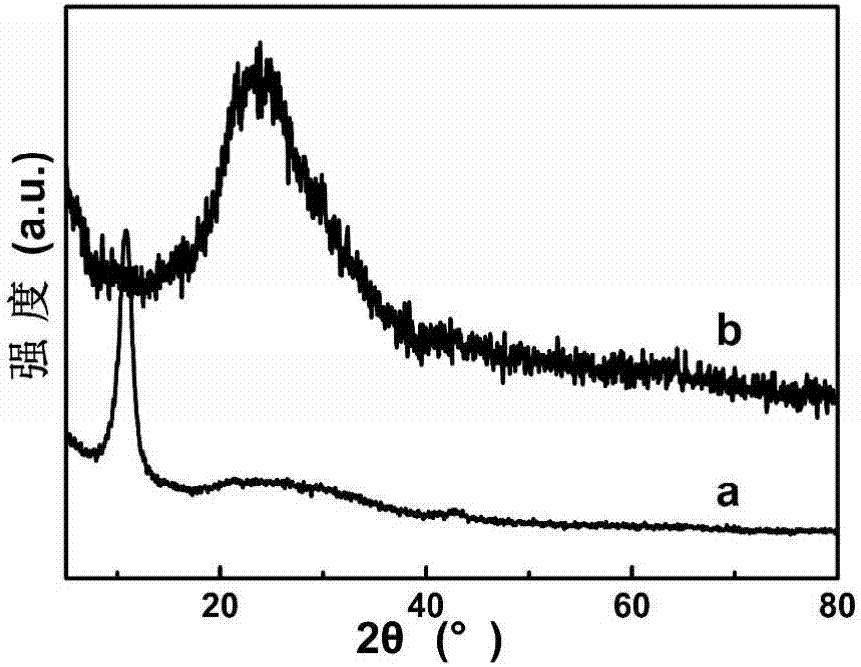

[0025] Preparation of graphene membrane electrode material: fully soak the graphene oxide membrane in a polytetrafluoroethylene reactor filled with concentrated sulfuric acid, and react at 160°C for 12h. Cool at room temperature, wash with distilled water until neutral, and dry at 60°C to prepare a graphene membrane electrode material. Such as figure 1 X-ray diffraction spectrogram for the prepared graphene film electrode material. It can be seen from the figure that the diffraction peak at 10.72° belongs to the C(001) crystal plane...

Embodiment example 2

[0026] Implementation Case 2 Preparation of Graphene Membrane Electrode Material

[0027] Preparation of graphene oxide film: Same as Example 1.

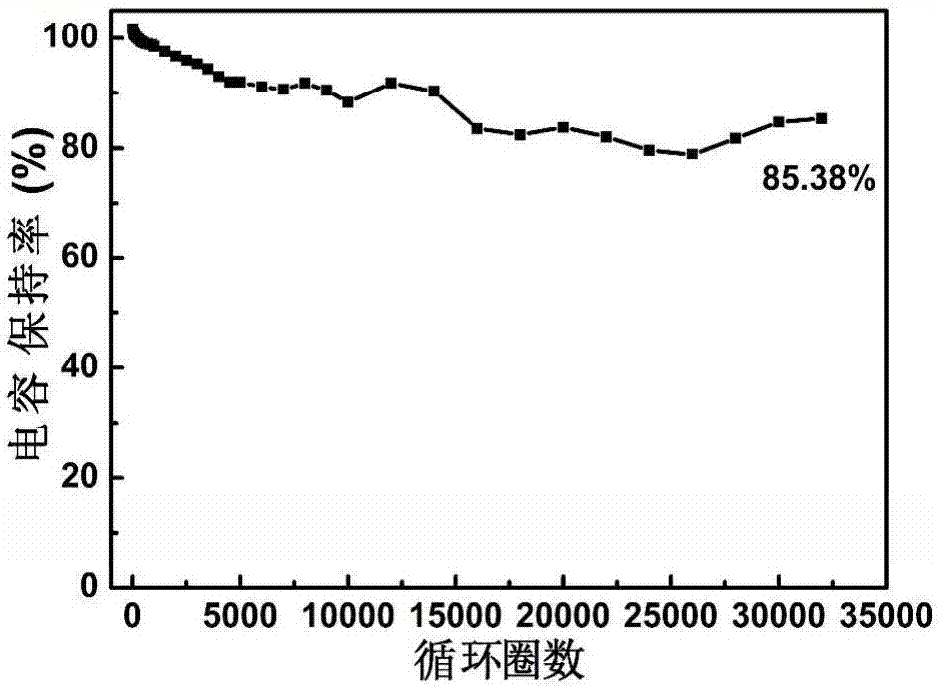

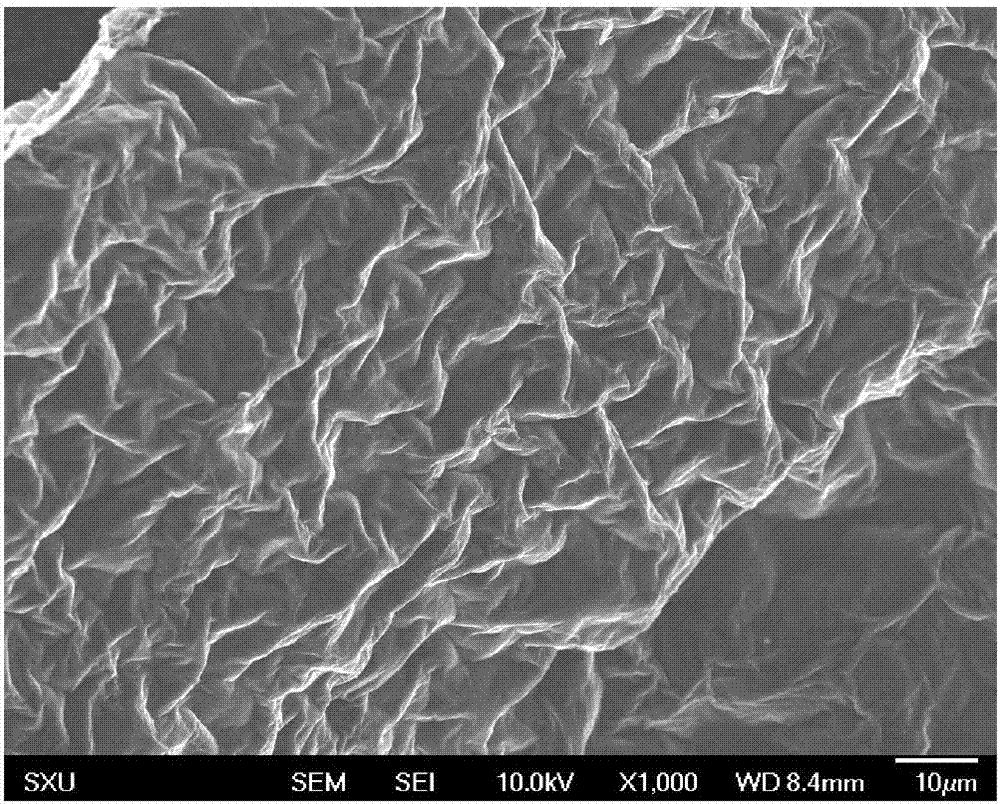

[0028] Preparation of graphene membrane electrode material: fully soak the graphene oxide membrane in a polytetrafluoroethylene reactor filled with concentrated sulfuric acid, and react at 140°C for 12h. Cool at room temperature, wash with distilled water until neutral, and dry at 60°C to prepare a graphene membrane electrode material. It can be seen from the scanning electron microscope that the surface of the prepared graphene membrane electrode material has a large number of wrinkles, such as image 3 shown. A symmetrical supercapacitor was assembled using it as an electrode material, and a two-electrode method was used at 1M H 2 SO 4 In the electrolyte, when the scan speed is 1mV s -1 , the mass specific capacitance reaches 156F g -1 , the volume specific capacitance reaches 309F cm -3 .

Embodiment example 3

[0029] Implementation Case 3 Preparation of Graphene Membrane Electrode Material

[0030] Preparation of graphene oxide film: Same as Example 1.

[0031] Preparation of graphene membrane electrode material: fully soak the graphene oxide membrane in a polytetrafluoroethylene reactor filled with concentrated sulfuric acid, and react at 180°C for 12h. Cool at room temperature, wash with distilled water until neutral, and dry at 60°C to prepare a graphene membrane electrode material. From the scanning electron microscope images, it can be seen that the surface of the prepared graphene membrane electrode has a large number of wrinkles, such as Figure 4 shown. A symmetrical supercapacitor was assembled using it as an electrode material, and a two-electrode method was used at 1M H 2 SO 4 In the electrolyte, when the scan speed is 1mV s -1 When the mass specific capacitance reaches 200F g -1 , the volume specific capacitance reaches 396F cm -3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume specific capacitance | aaaaa | aaaaa |

| Volume specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com