Preparation method of Bi2Fe4O9 material and application thereof

A technology of surfactants and precursors, applied in chemical instruments and methods, inorganic chemistry, hybrid capacitor electrodes, etc., can solve the problems of bismuth-iron compounds' catalytic and gas-sensing performance limitations, high sintering temperature, small specific surface area, etc., to achieve Excellent electrochemical performance, more voids, and high-quality specific capacitance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

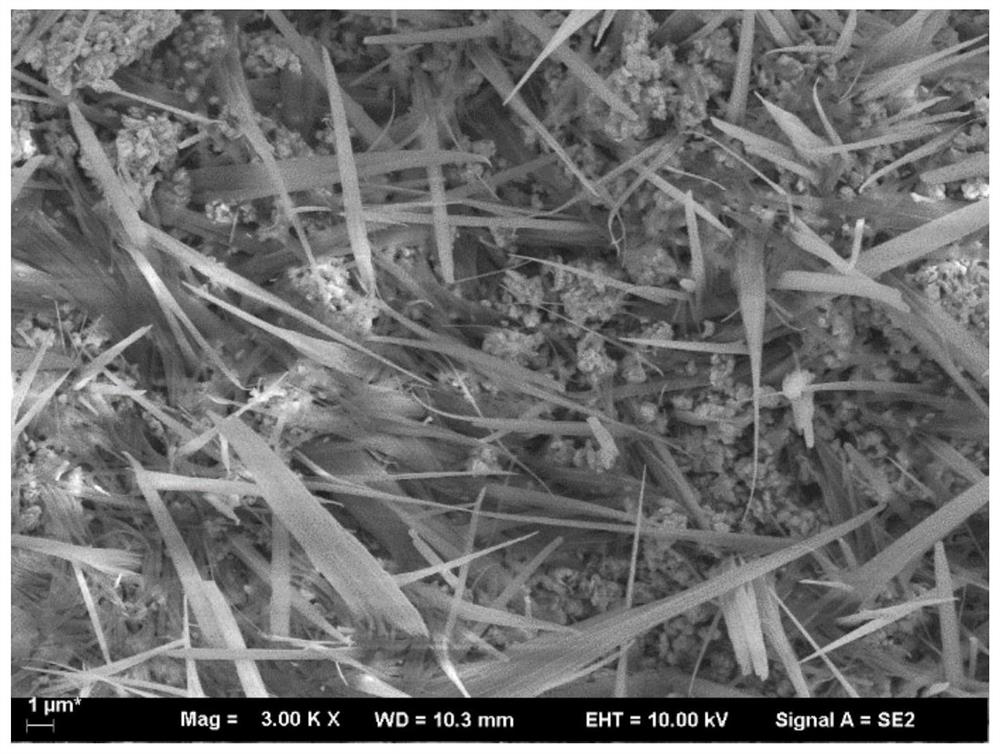

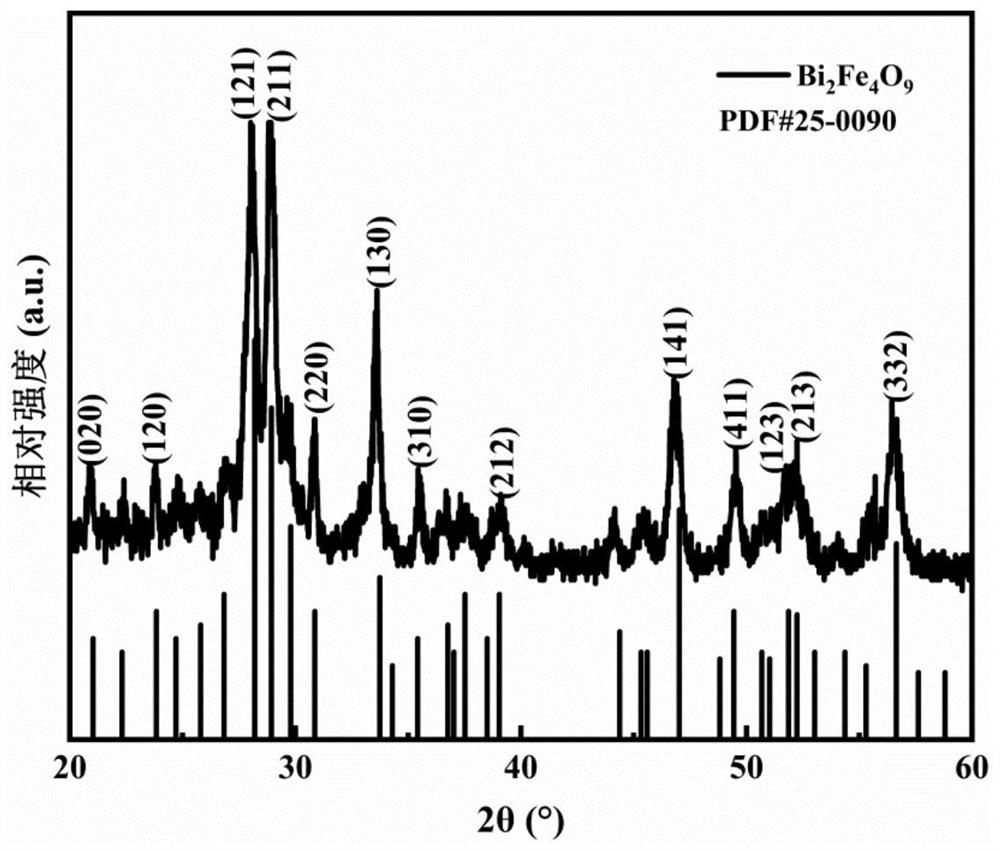

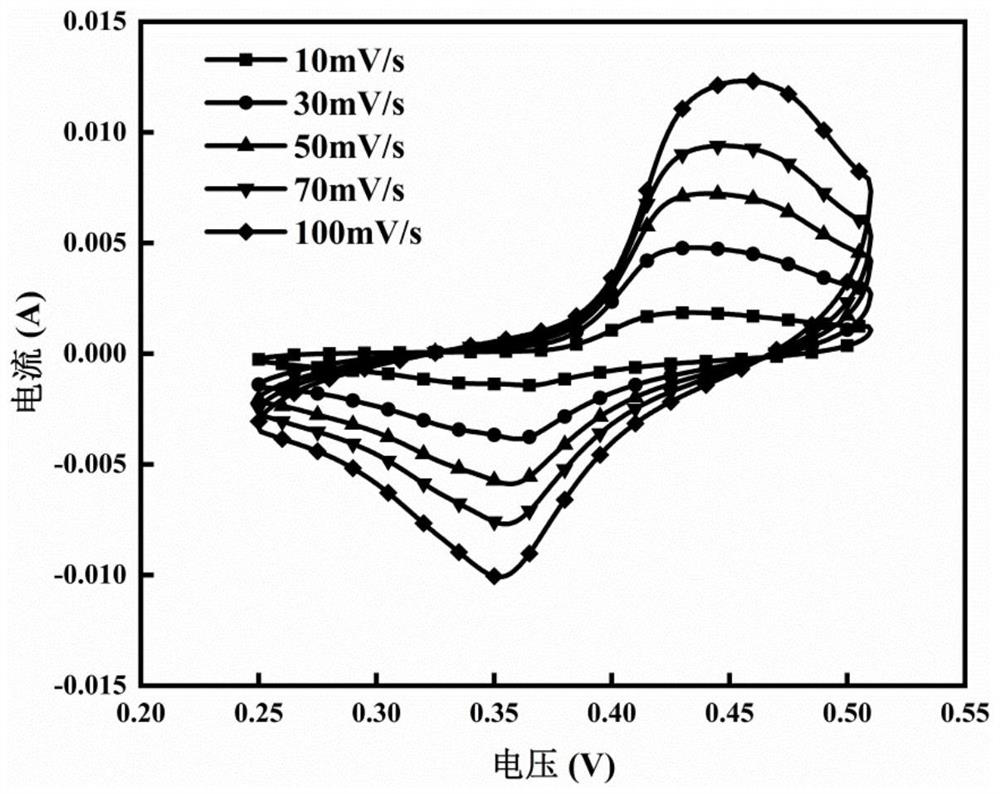

[0026] (1) Take 1-2ml of concentrated nitric acid and deionized water and mix and dilute according to the volume ratio of 1:9 to obtain dilute nitric acid. Weigh 0.49g of bismuth nitrate pentahydrate and 0.41g of ferric nitrate nonahydrate and dissolve them in the prepared dilute nitric acid. , stirred for 2 hours until completely dissolved to obtain a yellow solution, added 0.3 g of polyvinylpyrrolidone with a molecular weight of 1,300,000, and continued to stir for 4 hours to obtain a transparent and clear yellow mixed solution. Add 6mol / L sodium hydroxide solution dropwise to the mixed solution, and a reddish-brown precipitate appears; continue to add the sodium hydroxide solution dropwise until the pH value of the suspension is 12, accelerate magnetic stirring, and after stirring vigorously for 3 hours, place Pour the suspension into a clean polytetrafluoroethylene reactor lining, tighten the reactor, put it into a blast drying oven at 160°C for 15 hours, and then cool natu...

Embodiment 2

[0034] On the basis of Example 1, the difference of Example 1 is that 3 mol / L sodium hydroxide solution is added dropwise to the mixed solution.

Embodiment 3

[0036] On the basis of Example 1, the difference of Example 1 is that 8 mol / L sodium hydroxide solution is added dropwise to the mixed solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com