Preparation and application of lignin-based hierarchical porous carbon based on direct carbonization method

A lignin-based, hierarchically porous technology, applied in carbon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of increasing experimental costs, unfavorable for large-scale production, and high corrosion of equipment, achieving high specific surface area, The effect of excellent supercapacitor performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) 10g sodium lignosulfonate and 21.6g KOH aqueous solution with a mass fraction of 20% were added to the three-necked flask in turn and stirred until dissolved;

[0050] (2) After slowly adding 3.75 g of chloroacetic acid to the mixed solution in step (1), add 20 g of deionized water to stir the mixture until it is completely dissolved;

[0051] (3) After raising the temperature to 70 °C for 90 min, cooling to room temperature, and adjusting the pH to 10 with hydrochloric acid to obtain a mixed solution of potassium lignin, which is placed in a 70 °C oven to dry for use;

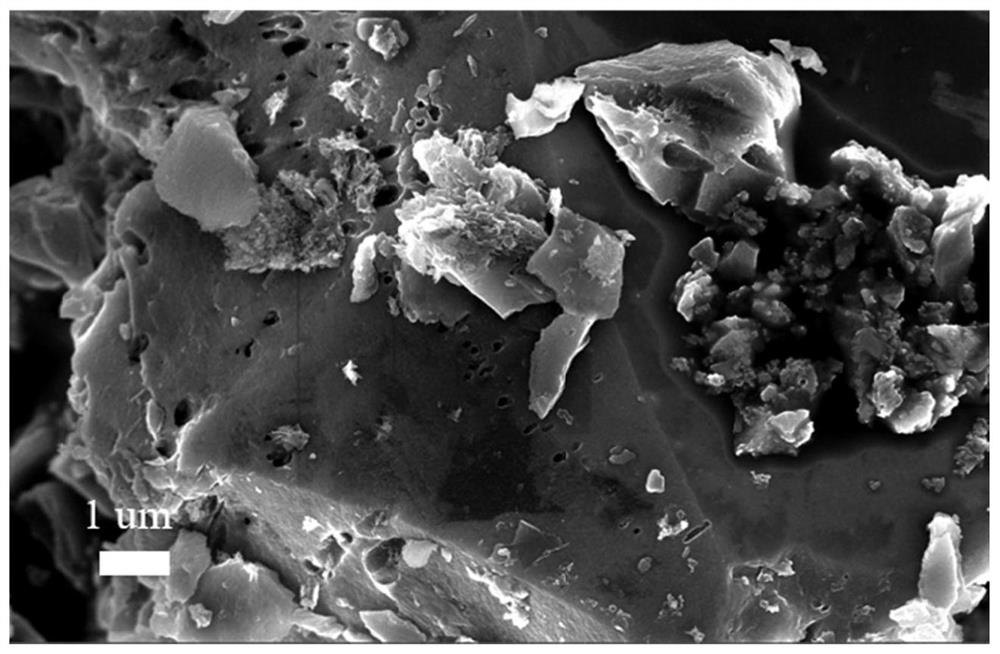

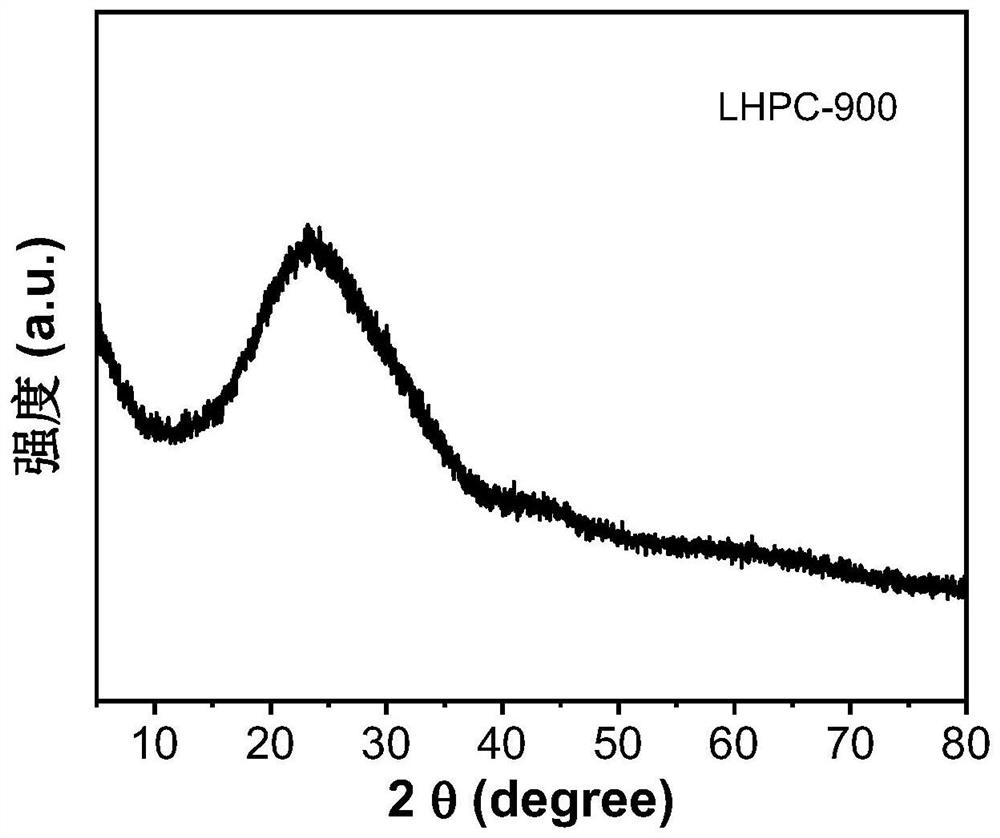

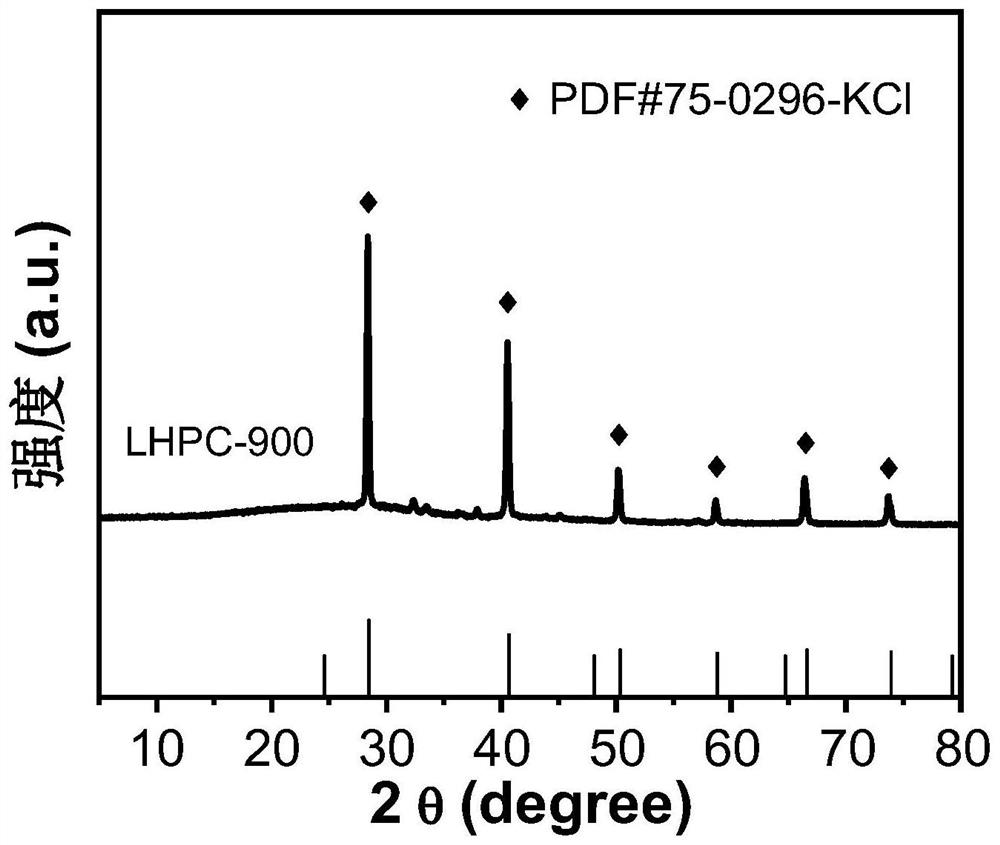

[0052] (4) The dried potassium lignin was heated at a rate of 5 °C / min, N 2 Gas, under the condition of gas flow rate of 40 mL / min, heat treatment at 900 °C for 2 h, after the reaction, take out and wash with 2 mol / L hydrochloric acid for 12 h, wash with deionized water until neutral, and drum at 80 °C. Air-dried for 12 h to obtain lignin-based hierarchical porous carbon, named LHPC-900.

[0053] ...

Embodiment 2

[0060] (1) Add 15 g of alkali lignin and 6 g of KOH aqueous solution with a mass fraction of 10% into the three-necked flask in turn, and add 20 g of deionized water and stir for 1 h until completely dissolved;

[0061] (2) After the temperature was raised to 70°C for 90min, the pH was adjusted to 9 with hydrochloric acid to obtain a mixed solution of potassium lignin, which was put into a blast oven at 70°C for drying for 24 hours before use;

[0062] (3) The dried potassium lignin was heated at a heating rate of 5 °C / min, N 2 The gas was treated at 700 °C for 2 h under the condition of a gas flow of 40 mL / min. After the reaction, it was taken out and washed with 2 mol / L hydrochloric acid for 12 h, washed with deionized water until neutral, and dried at 80 °C. Air-dried for 12 h to obtain lignin-based hierarchical porous carbon, which was named LPC-700;

[0063] Electrodes were prepared by using LPC-700: conductive carbon black: polytetrafluoroethylene (PTFE) in a mass ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com