Graphene with high volumetric specific capacitance and preparation method thereof

A graphene, graphene sheet technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems such as the inability to apply large-capacity supercapacitors and other electrical devices, the small size of graphene, etc., to improve energy density, volume specific capacitance, etc. High, simple process results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

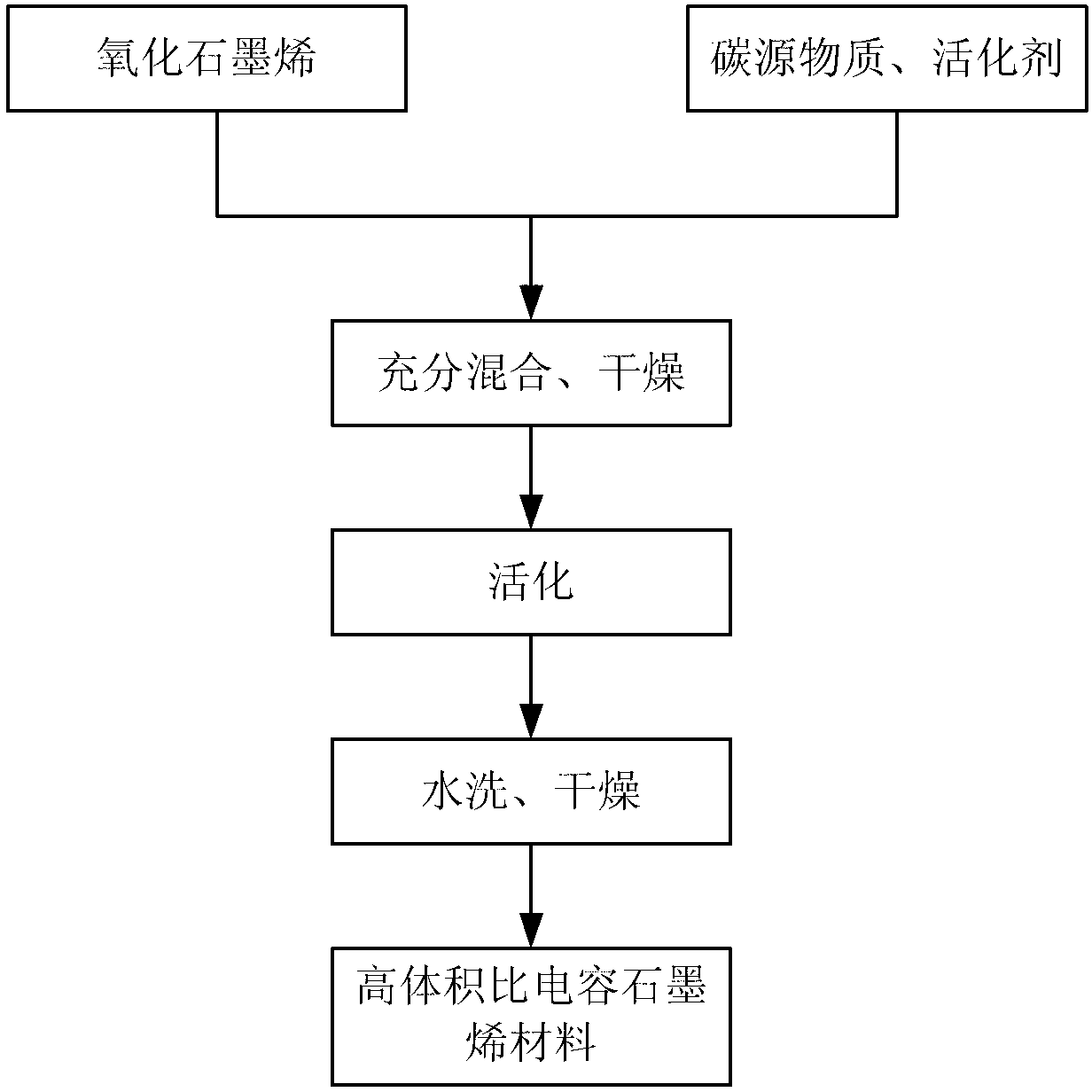

[0063] A preparation method for high volume ratio capacitance graphene, comprising the steps of:

[0064] (1) Take graphite oxide prepared by Hummers method, and obtain graphene oxide powder after microwave exfoliation;

[0065] (2) Weigh 3g of graphene oxide powder obtained in step (1), 0.5g of charcoal, 15g of KOH, fully mix, stir and dry;

[0066] (3) Place the mixture obtained in step (2) in a vacuum tube furnace. After removing the air in the furnace, feed argon gas with a purity of 99.99% into the vacuum tube furnace at a flow rate of 100 sccm, and react at 800°C for 1.5 h;

[0067] (4) After the reaction is completed, the temperature is naturally lowered to room temperature, washed, and dried to obtain a high specific surface graphene material with increased volume specific capacitance. figure 1 It is a schematic diagram of the preparation process of high volume ratio capacitance graphene described in embodiment 1;

[0068] The specific surface area of the prepared...

Embodiment 2

[0074] A preparation method for high volume ratio capacitance graphene, comprising the steps of:

[0075] (1) Take graphite oxide prepared by Hummers method, and obtain graphene oxide powder after microwave exfoliation;

[0076] (2) Weigh 3g of graphene oxide powder obtained in step (1), 1g of sawdust, 18g of KOH, fully mix, stir and dry;

[0077] (3) Place the mixture obtained in step (2) in a vacuum tube furnace, and after removing the air in the furnace, feed argon gas with a purity of 99.99% into the vacuum tube furnace at a flow rate of 120 sccm, and react at 900°C for 1 hour ;

[0078] (4) After the reaction is completed, the temperature is naturally lowered to room temperature, washed, and dried to obtain a high specific surface graphene material with increased volume specific capacitance.

[0079] The specific surface area of the prepared graphene material is 1996.9m 2 / g (measurement method is the same as Example 1).

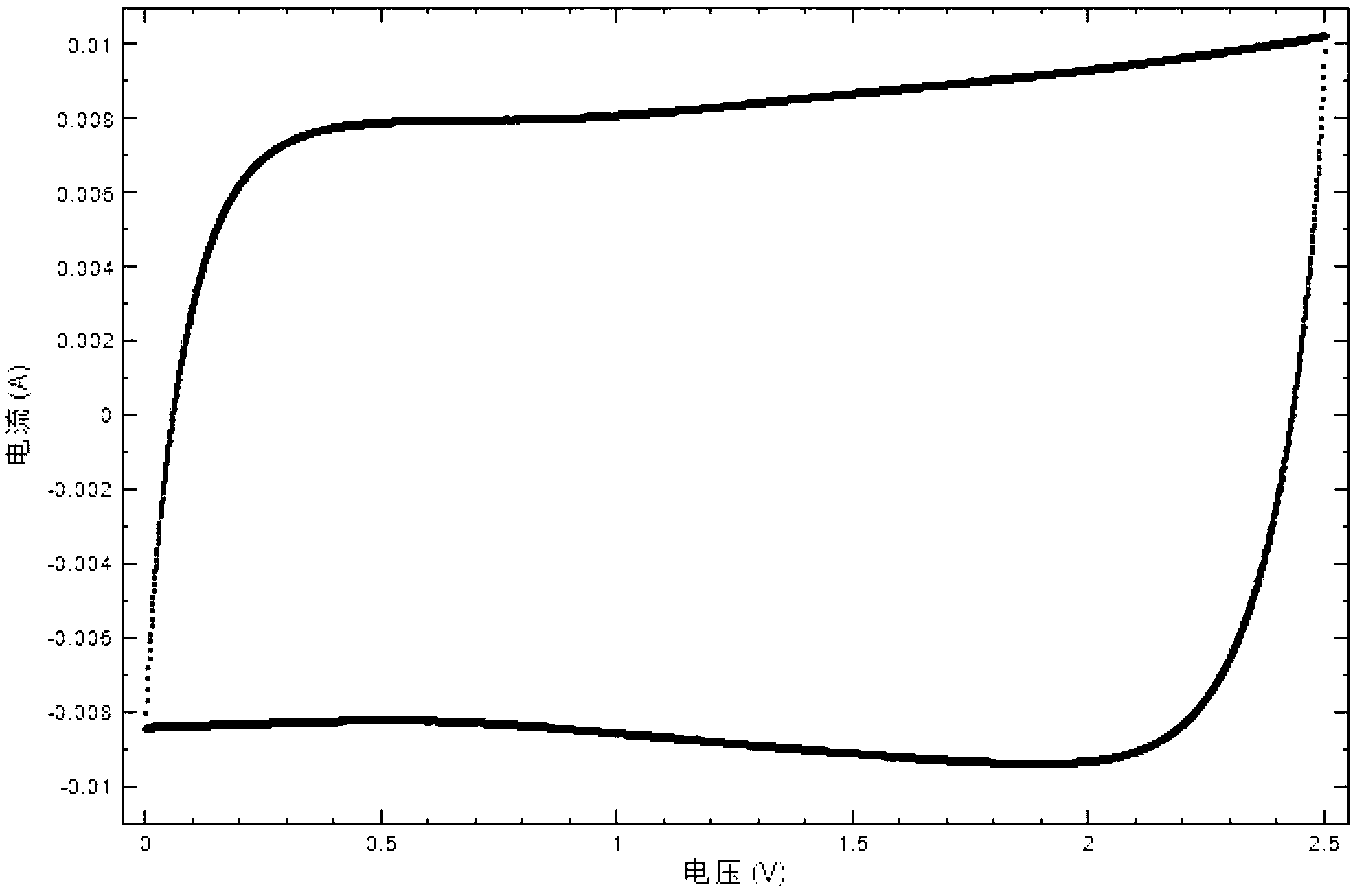

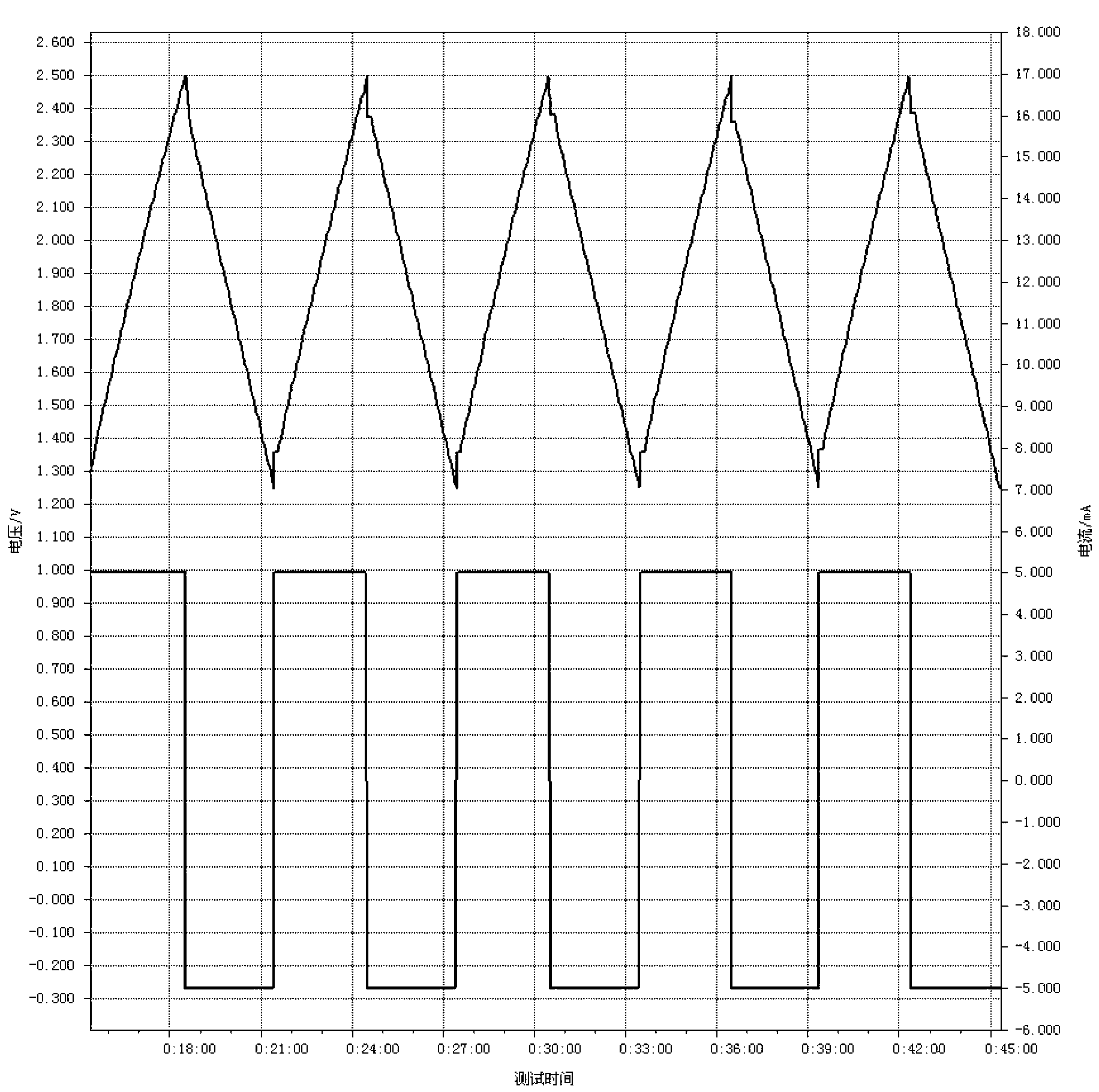

[0080] Performance Testing:

[0081] Test ...

Embodiment 3

[0083] A preparation method for high volume ratio capacitance graphene, comprising the steps of:

[0084] (1) Take graphite oxide prepared by Hummers method, and obtain graphene oxide powder after microwave exfoliation;

[0085] (2) Weigh 3g of graphene oxide powder obtained in step (1), 1g of petroleum coke, 15g of KOH, fully mix, stir and dry;

[0086] (3) Place the mixture obtained in step (2) in a vacuum tube furnace, and after removing the air in the furnace, feed argon gas with a purity of 99.99% into the vacuum tube furnace at a flow rate of 60 sccm, and react at 1200°C for 0.5 h;

[0087] (4) After the reaction is completed, the temperature is naturally lowered to room temperature, washed, and dried to obtain a high specific surface graphene material with increased volume specific capacitance.

[0088] The specific surface area of the prepared graphene material is 2150.2m 2 / g (measurement method is the same as Example 1).

[0089] Performance Testing:

[0090] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com