Method for preparing high-volumetric-specific-capacitance graphene by using metal cation assisted heat treatment technology

A technology of metal cations and metal ion salts, applied in the field of preparing graphene with high volume specific capacitance, can solve the problems of low bulk density and low volume specific capacitance, and achieve high bulk density, large volume specific capacitance and high volume specific capacitance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: This implementation mode is realized through the following steps:

[0035] Step 1, graphene oxide is evenly dispersed in deionized water in a ratio of 1:500 by weight ratio of graphene oxide and deionized water;

[0036] Step 2, then add anhydrous LiCl according to the weight ratio of graphene oxide and LiCl is 1:75, mix well, and then rotate at 11000r min -1Centrifuge for solid-liquid separation, and vacuum dry at 100°C for 12 hours;

[0037] Step 3, then put it into a tube furnace, heat treatment at 400°C for 60 minutes, wash with water 4 times, the ion concentration of the supernatant is less than 10 -3 mol L -1 , and then dried in vacuum at 80° C. for 4 h to obtain graphene powder.

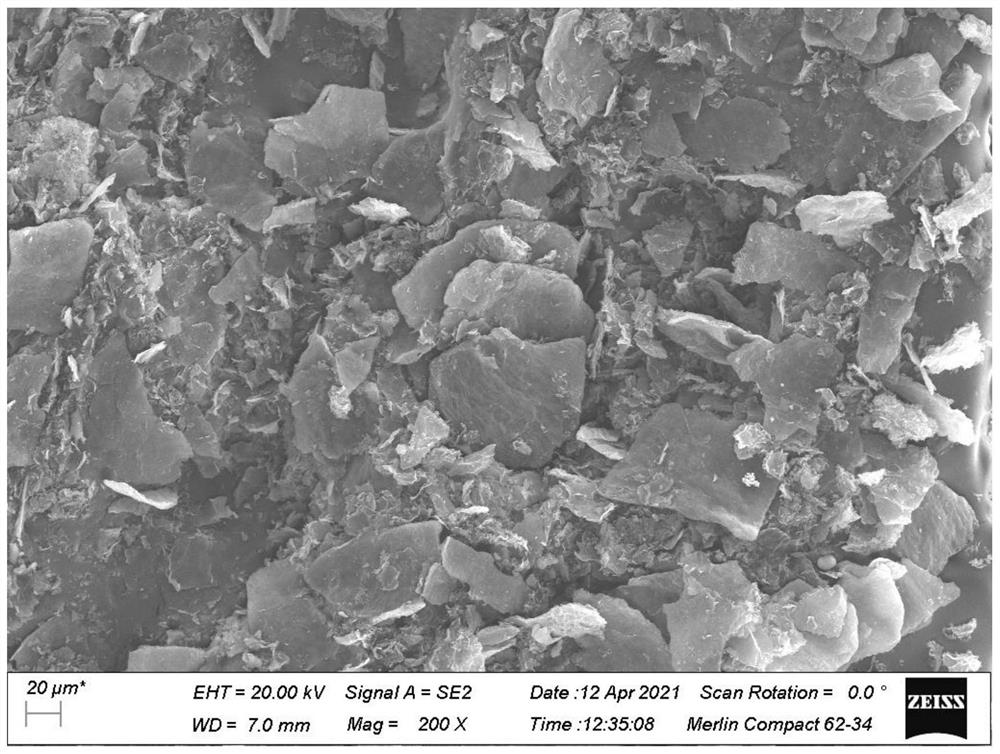

[0038] The graphene powder prepared by the method of this embodiment is observed under a scanning electron microscope as figure 1 shown, from figure 1 It can be seen that the prepared graphene sheets in this embodiment 1 are well stacked and assembled together, and th...

Embodiment 2

[0046] Embodiment 2: This implementation mode is realized through the following steps:

[0047] Step 1, graphene oxide is evenly dispersed in deionized water in a ratio of 1:500 by weight ratio of graphene oxide and deionized water;

[0048] Step 2, then add anhydrous LiCl according to the weight ratio of graphene oxide and LiCl is 1:75, mix well, and then rotate at 11000r min -1 Centrifuge for solid-liquid separation, and vacuum dry at 100°C for 12 hours;

[0049] Step 3, then put it into a tube furnace, heat treatment at 400°C for 60 minutes, wash with water 4 times, the ion concentration of the supernatant is less than 10 -3 mol L -1 , and then dried in vacuum at 80° C. for 4 h to obtain graphene powder.

Embodiment 3

[0050] Embodiment 3: This implementation mode is realized through the following steps:

[0051] Step 1, graphene oxide is evenly dispersed in deionized water in a ratio of 1:500 by weight ratio of graphene oxide and deionized water;

[0052] Step 2, then add anhydrous LiCl according to the weight ratio of graphene oxide and LiCl is 1:400, mix well, and then rotate at 11000r min -1 Centrifuge for solid-liquid separation, and vacuum dry at 100°C for 12 hours;

[0053] Step 3, then put it into a tube furnace, heat treatment at 400°C for 60 minutes, wash with water 4 times, the ion concentration of the supernatant is less than 10 -3 mol L -1 , and then dried in vacuum at 80° C. for 4 h to obtain graphene powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com