A kind of carbon coated graphene, preparation method and application thereof

A graphene and carbon coating technology, which is applied in the manufacture of hybrid/electric double layer capacitors, electrical components, battery electrodes, etc. The effect of increased volume specific capacitance, increased energy density, and stable cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A preparation method of carbon-coated graphene, comprising the steps of:

[0069] (1) Pre-treatment: Take the graphite oxide prepared by the Hummers method, and obtain graphene oxide powder after microwave peeling, and set aside; weigh 1g of sucrose and dissolve it in 100mL deionized water to fully dissolve, add 3g of graphene oxide powder and stir for 5h, then add 15g of KOH, fully mixed, stirred and dried;

[0070] (2) Put the mixture obtained in step (1) in a vacuum tube furnace, and after removing the air in the furnace, pass argon gas with a purity of 99.99% into the vacuum tube furnace at a flow rate of 100 sccm, and react at 800°C for 2 hours ;

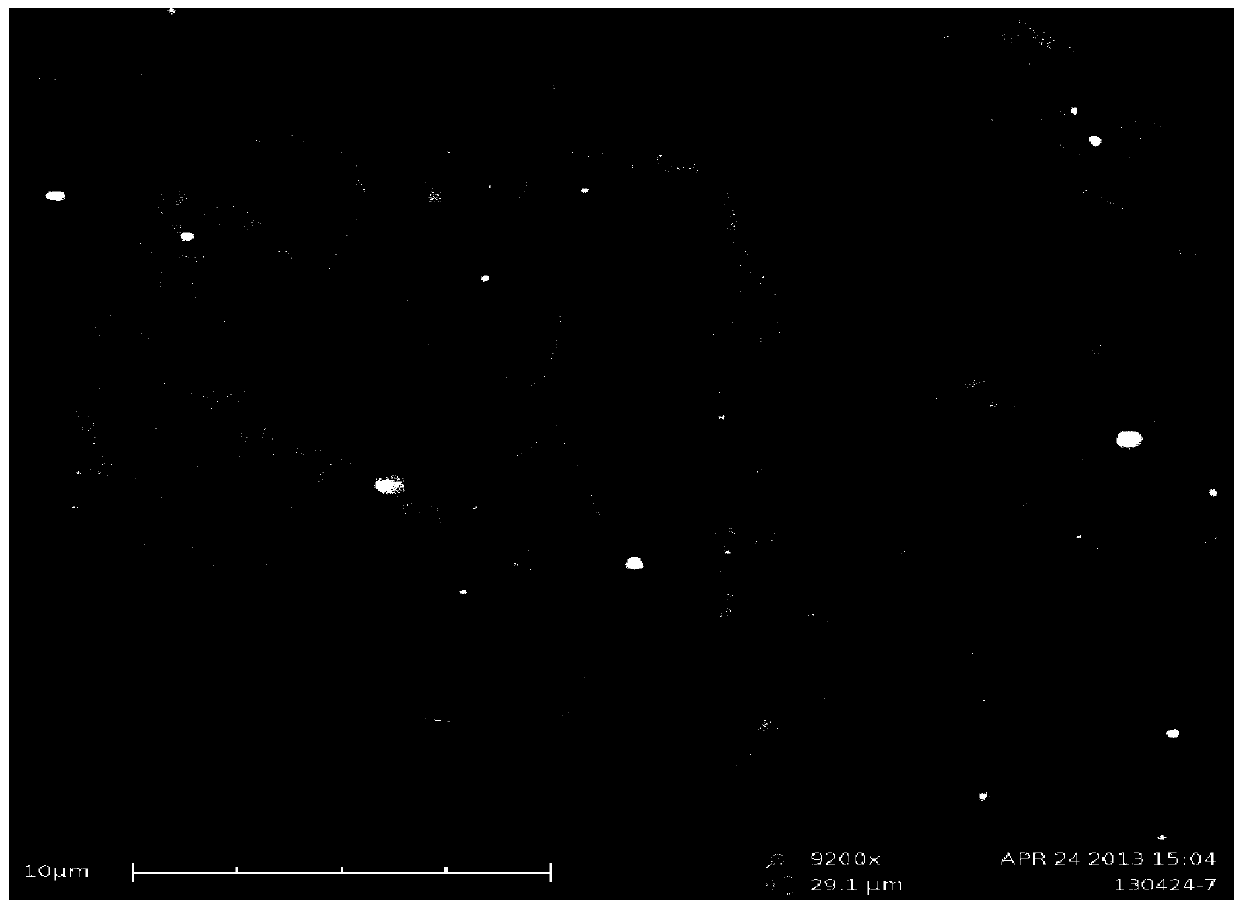

[0071] (3) After the reaction is completed, the temperature is naturally cooled to room temperature, washed, and dried to obtain a carbon-coated graphene material with increased volume specific capacitance. figure 1 It is the SEM figure of carbon-coated graphene described in embodiment 1;

[0072] The specific surface...

Embodiment 2

[0078] A preparation method of carbon-coated graphene, comprising the steps of:

[0079] (1) Pretreatment: Take the graphite oxide prepared by the Hummers method, and obtain graphene oxide powder after microwave peeling, and set aside; weigh 2g of glucose and dissolve it in 100mL deionized water to fully dissolve, add 3g of graphene oxide powder and stir for 10h, then add 18g of KOH, fully mixed, stirred and dried;

[0080] (2) Place the mixture obtained in step (1) in a vacuum tube furnace, and after removing the air in the furnace, pass argon gas with a purity of 99.99% into the vacuum tube furnace at a flow rate of 100 sccm, and react at 900°C for 1 hour ;

[0081] (3) After the reaction is completed, the temperature is naturally cooled to room temperature, washed, and dried to obtain a carbon-coated graphene material with increased volume specific capacitance.

[0082] The specific surface area of the prepared graphene material is 2590m 2 / g (measurement method is the...

Embodiment 3

[0086] A preparation method of carbon-coated graphene, comprising the steps of:

[0087] (1) Pretreatment: Take the graphite oxide prepared by the Hummers method, and obtain graphene oxide powder after microwave peeling, and set aside; weigh 0.5g fructose and dissolve it in 100mL deionized water to fully dissolve, add 3g graphene oxide powder and stir for 15h, then Add 12g of KOH, fully mix, stir and dry;

[0088](2) Place the mixture obtained in step (1) in a vacuum tube furnace. After removing the air in the furnace, feed argon gas with a purity of 99.99% into the vacuum tube furnace at a flow rate of 100 sccm, and react at 1000°C for 1.5 h;

[0089] (3) After the reaction is completed, the temperature is naturally cooled to room temperature, washed, and dried to obtain a carbon-coated graphene material with increased volume specific capacitance.

[0090] The specific surface area of the prepared graphene material is 2995m 2 / g (measurement method is the same as Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com