Preparation method and application of a carbon material/redox electrolyte composite material

A technology of composite materials and carbon materials, which is applied in the field of preparation of carbon materials/redox electrolyte composite materials, can solve the problems of low volume specific capacitance and low packing density of active materials of electrochemical capacitors, achieve high-quality specific capacitance and improve quality Specific capacitance and volume specific capacitance, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of preparation method of graphene / redox electrolyte composite material, comprises the steps: 4g graphite powder is joined in the concentrated sulfuric acid (92mL) that places ice-water bath, stirs; Subsequently, add 9gKMnO 4 Carry out reaction (reaction temperature is 50 ℃); Treat that after reaction finishes, add H 2 o 2 Reduction of unreacted substances; centrifugation and dialysis to obtain graphene aqueous solution. Take 10 mL of the prepared graphene aqueous solution (solid content is 8 mg / mL), 10 mL of deionized water and 165 mg of potassium iodide powder, transfer to a 25 mL polytetrafluoroethylene reactor for hydrothermal reaction, and obtain graphene hydrogel. The reaction temperature was 180°C, and the reaction time was 6 hours. Put the graphene hydrogel in a drying oven and dry it in a vacuum environment at 60°C for 12 hours. Subsequently, the obtained material was washed with deionized water and dried at 60° C. to obtain a graphene / potassium iodide...

Embodiment 2

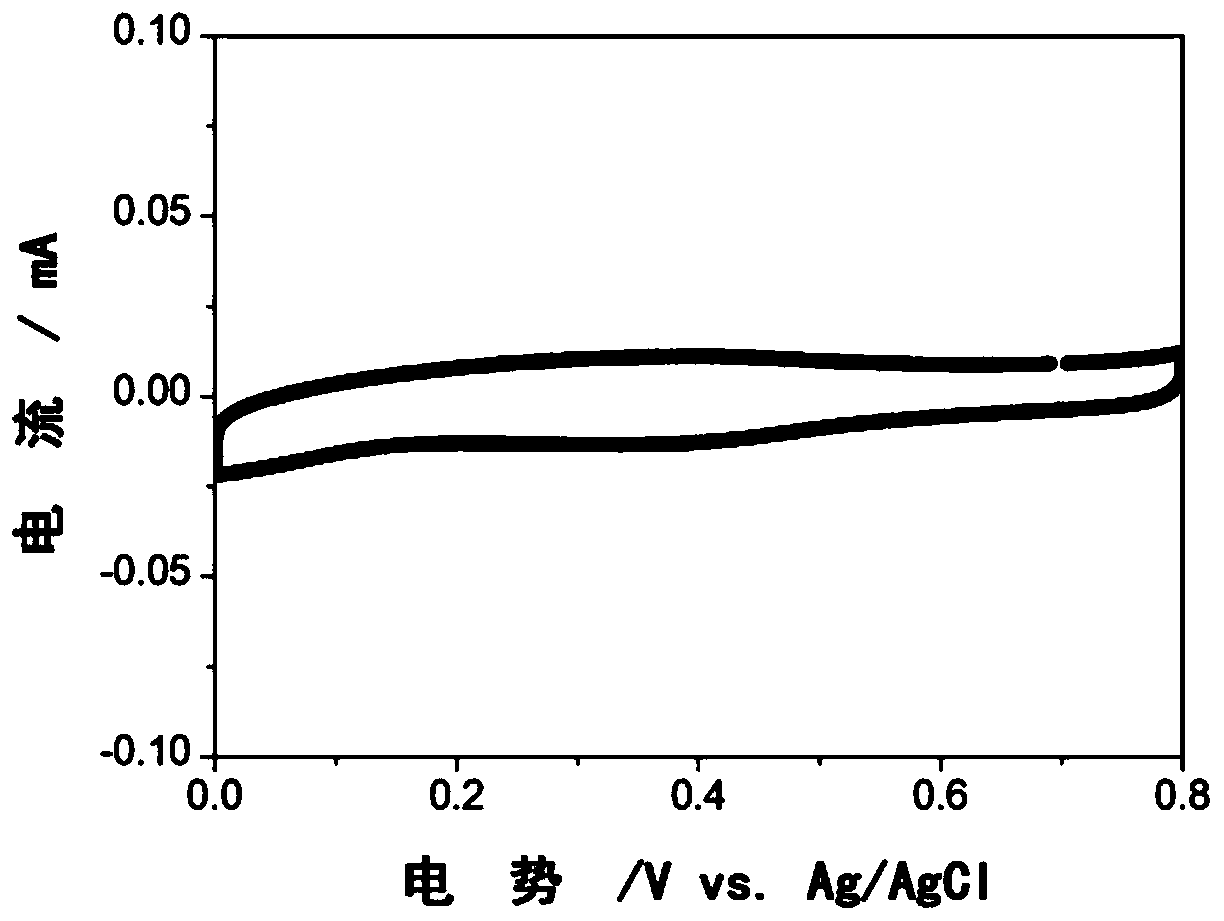

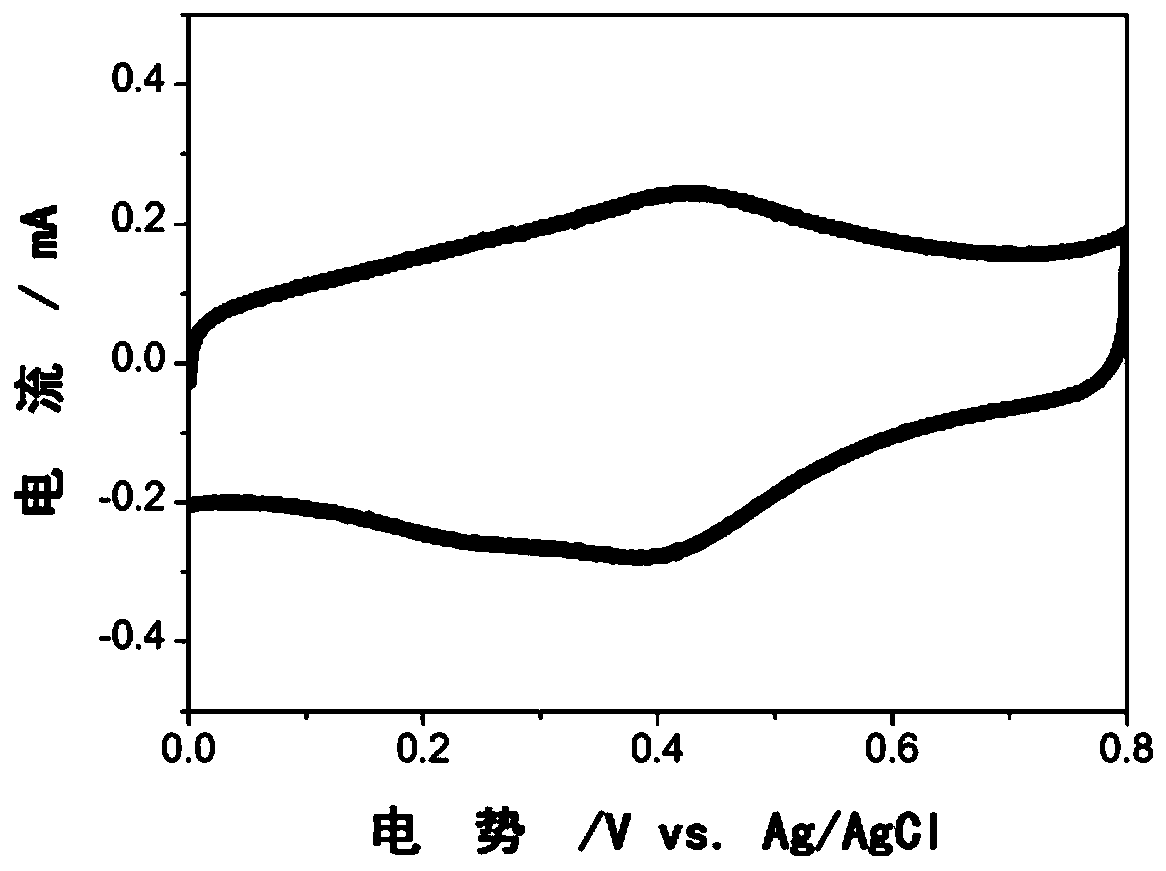

[0041] The graphene / potassium iodide composite material that embodiment 1 is made is as working electrode (80wt.% graphene, 10wt.% conductive additive, coating 316 stainless steel current collectors after 10wt.% binding agent mixes uniformly), and platinum sheet is as counter electrode electrode, silver chloride as reference electrode, in 1M H 2 SO 4 In the electrolyte, it is assembled into a three-electrode system to test the electrochemical performance of the electrodes. figure 2 It is the cyclic voltammetry curve of the electrode at a scan rate of 0.5mV / s. After testing, the electrode has an obvious redox peak at a potential of 0.4V (vs.Ag / AgCl), and its mass specific capacitance is 222F g -1 , the volume specific capacitance is 290F L -1 . Figure 4 It is the impedance spectrum of high-density graphene electrode and graphene / redox electrolyte composite electrode, after testing this graphene / potassium iodide composite material has the charge transfer impedance ( Figur...

Embodiment 3

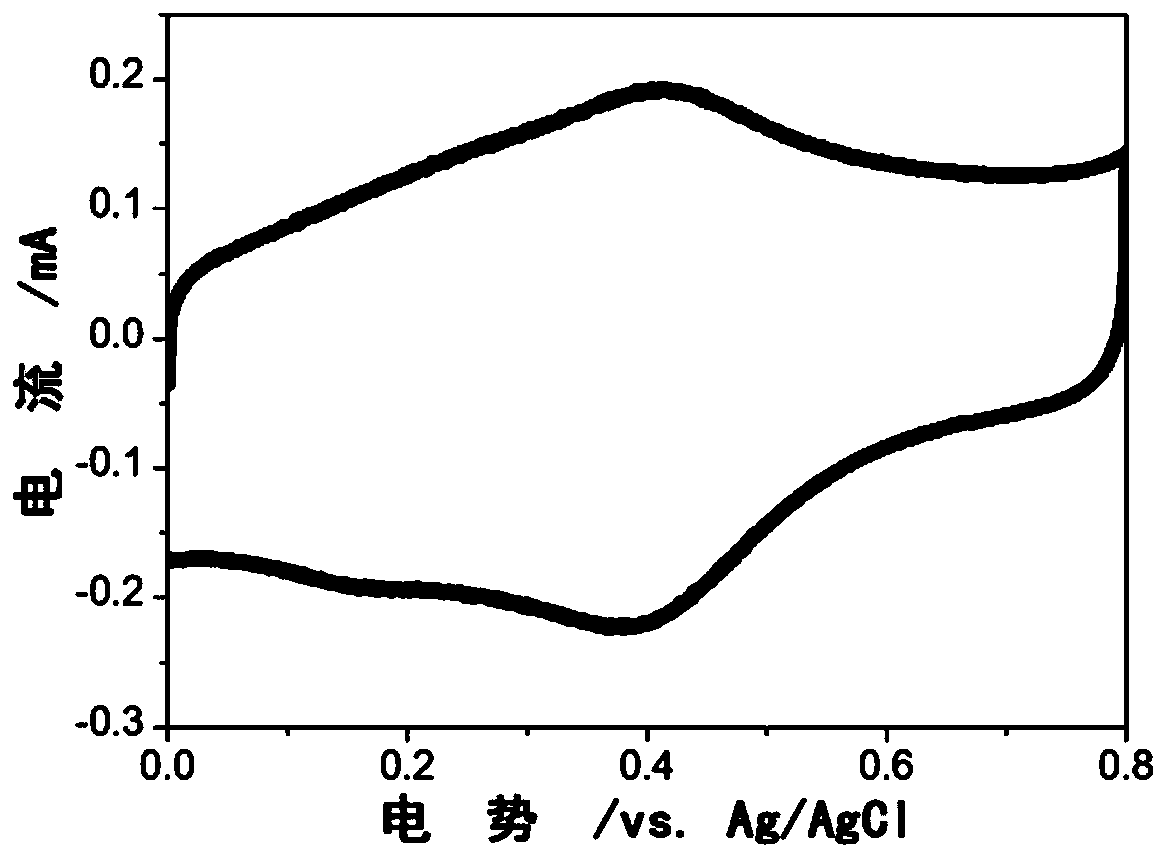

[0043] The graphene / potassium iodide composite material that embodiment 1 is prepared is prepared as electrode (80wt.% graphene, 10wt.% conductive additive, 10wt.% binder is coated with 316 stainless steel current collector after mixing uniformly), and simultaneously as positive Negative electrode (mass ratio of positive and negative electrodes is 1 to 1), and 1M H 2 SO 4 The electrolyte and the glass fiber diaphragm are assembled into a supercapacitor. Image 6 It is the cyclic voltammetry curve of the supercapacitor under the voltage window of 0-1.4V, and the mass energy density of the supercapacitor is tested to be 39Whkg -1 , the volumetric energy density can reach 50.7Wh L -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com