Method for Improving Volume Specific Capacitance of Rice Husk Based Capacitor Carbon

A capacitive carbon, volume ratio technology, applied in hybrid capacitor electrodes, chemical instruments and methods, hybrid/electric double layer capacitor manufacturing, etc., can solve the poor conductivity of rice husk capacitor carbon, difficulty in transporting electrolyte ions, affecting volume specific capacitance, etc. problems, to achieve the effect of improving electrochemical performance, pollution-free price, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

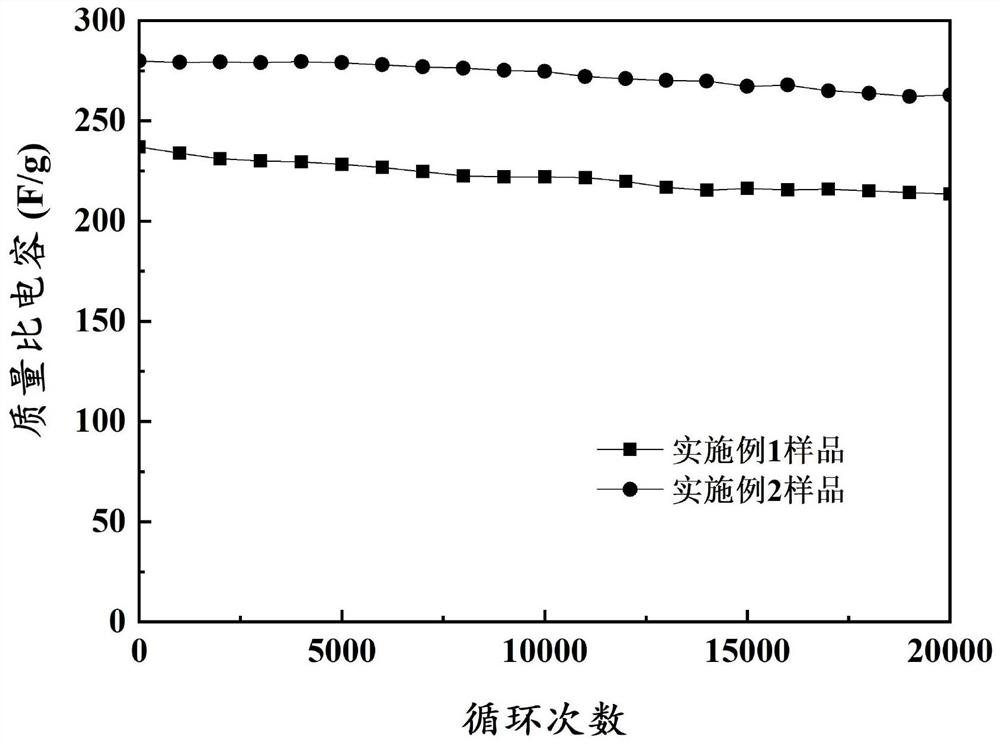

Embodiment 1

[0038] (1) The raw material rice husk is screened to remove impurities, and crushed to a particle size of 10 mm to 20 mm to obtain rice husk powder, which is set aside;

[0039] (2) Place the rice husk powder obtained in step (1) in a tube furnace, and under the protection of nitrogen, heat up to 200°C at a heating rate of 5°C / min, pyrolysis and dehydration for 0.5h, and then heat up to 200°C at a heating rate of 5°C / min The heating rate is increased to 500°C, pyrolyzed for 1 hour, and pyrolytic charcoal is obtained;

[0040] (3) Mix the pyrolytic carbon obtained in step (2) with the NaOH solution with a concentration of 5wt% according to the solid-to-liquid ratio of 1Kg:10L, heat and reflux for 2h, suction filter after cooling down to room temperature, wash the filter cake with water until neutral, and dry , to obtain desiliconized rice husk pyrolytic carbon;

[0041] (4) Add the desiliconized rice husk pyrolytic carbon and sodium hydroxide obtained in step (3) into the high...

Embodiment 2

[0043] (1) The raw material rice husk is screened to remove impurities, crushed to a particle size of 10mm-20mm, and mixed with NH with a concentration of 5wt%. 4 The OH solution was added into the reaction kettle according to the solid-to-liquid ratio of 1Kg: 10L, sealed and heated to 120°C, pressurized and impregnated for 1h, and filtered after cooling down to room temperature, the filtrate was recycled after adjusting the concentration, and the filter cake was dried at 100°C to obtain Catalyst treatment rice husk, standby;

[0044] (2) Place the catalyst-treated rice husk obtained in step (1) in a tube furnace, and under the protection of nitrogen, heat up to 200°C at a heating rate of 5°C / min, pyrolyze for 0.5h, and then heat up to 200°C at a heating rate of 5°C / min. The heating rate is increased to 500°C, pyrolyzed for 1 hour, and pyrolytic charcoal is obtained;

[0045](3) The pyrolytic charcoal obtained in step (2) is mixed with a NaOH solution having a concentration o...

Embodiment 3

[0048] (1) The raw material rice husk is screened to remove impurities, crushed to a particle size of 10mm-20mm, and mixed with NH with a concentration of 5wt%. 4 The OH solution was added into the reaction kettle according to the solid-to-liquid ratio of 1Kg:10L, sealed and heated to 120°C, pressurized and impregnated for 1h, cooled to room temperature and filtered with suction, the filtrate was recycled after adjusting the concentration, and the filter cake was dried at 100°C to obtain Catalyst treatment rice husk, standby;

[0049] (2) Place the catalyst-treated rice husk obtained in step (1) in a tube furnace, and under the protection of nitrogen, first raise the temperature to 200°C at a heating rate of 5°C / min, pyrolyze for 0.5h, and then raise the temperature at a heating rate To 500°C, pyrolyze for 1 hour to obtain catalytic pyrolytic carbon;

[0050] (3) The catalytic pyrolytic carbon obtained in step (2) is mixed with a NaOH solution having a concentration of 5wt% a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com