Polymer electrolyte containing zwitter-ionic groups and redox groups and preparation method of polymer electrolyte

A zwitterion and polymer technology, applied in the field of electrochemistry, can solve the problems of inability to meet the use of solid-state supercapacitors, and achieve the effects of excellent electrochemical performance and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

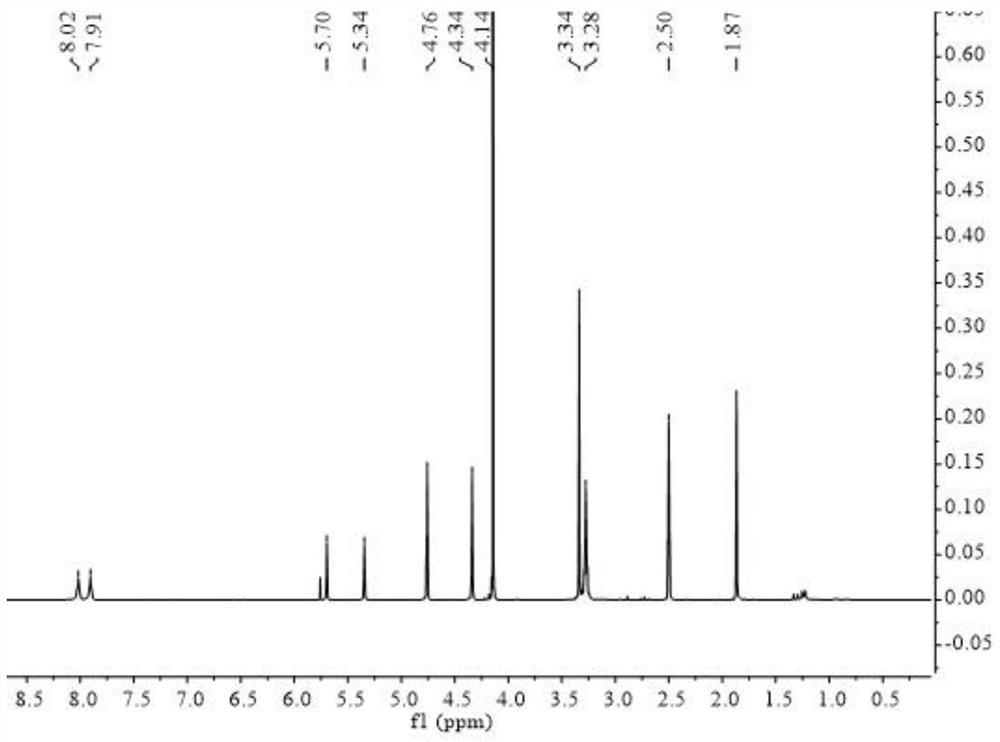

Embodiment 1

[0041] A method for preparing a polymer electrolyte, comprising the steps of:

[0042] S1, prepare dimethyl sulfoxide (DMSO) / absolute ethanol=9 / 1 solution (S), pass nitrogen gas to remove oxygen for 2 hours in advance, and set aside;

[0043] S2, weigh 68.41mg of monomer II-1 and 295.27mg of monomer III-1 in reaction test tubes, deoxygenate them with double row tubes, add 1.5mL of S, and dissolve them into solution M;

[0044] S3, weigh 1.97mg of BPO in the reaction test tube, use a double-row tube to deoxygenate it, add 0.5ml of S, and dissolve it into a solution R;

[0045] S4, adding the solution R into the solution M, heating to 70°C, reacting for 8 hours, filtering, dialysis of the filtrate for 48 hours, and freeze-drying for 48 hours to obtain the polymer electrolyte I-1.

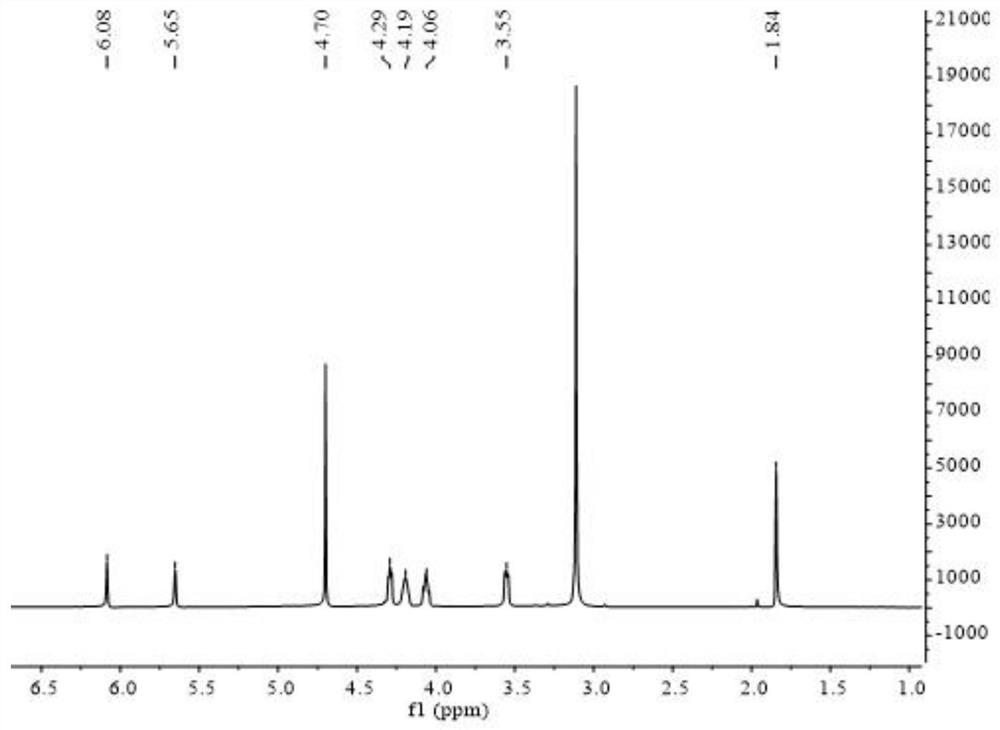

Embodiment 2

[0047] A method for preparing a polymer electrolyte, comprising the steps of:

[0048] S1, prepare dimethyl sulfoxide (DMSO) / absolute ethanol=8 / 1 solution (S), pass nitrogen gas to remove oxygen for 2 hours in advance, and set aside;

[0049] S2, weigh 73.91mg of monomer II-2 and 319.01mg of monomer III-2 in reaction test tubes, deoxygenate them with double row tubes, add 1.5mL of S, and dissolve them into solution M;

[0050] S3, weigh 2.13mg of BPO in the reaction test tube, use a double-row tube to deoxygenate it, add 0.5ml of S, and dissolve it into a solution R;

[0051] S4, add the solution R into the solution M, heat to 70° C., react for 12 hours, filter, dialyze the filtrate for 48 hours, and freeze-dry for 72 hours to obtain the polymer electrolyte I-2.

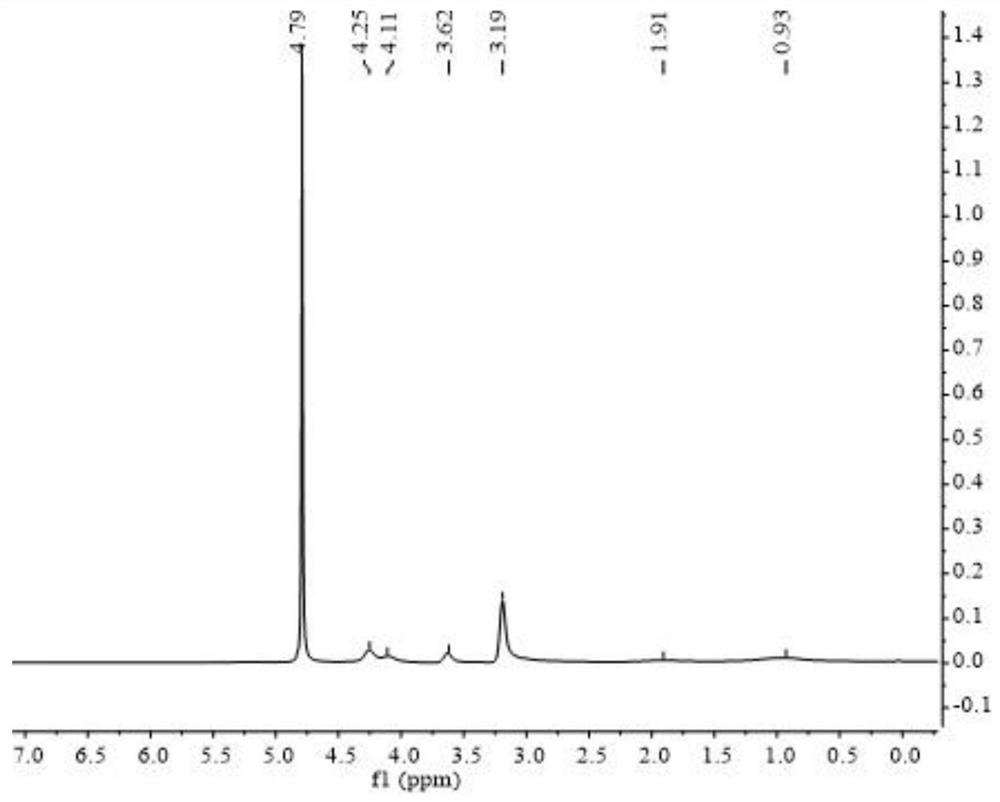

Embodiment 3

[0053] A method for preparing a polymer electrolyte, comprising the steps of:

[0054] S1, prepare dimethyl sulfoxide (DMSO) / absolute ethanol = 19 / 1 solution (S), pass nitrogen gas to remove oxygen for 2 hours in advance, and set aside;

[0055] S2, weigh 68.41mg of monomer II-3 and 590.54mg of monomer III-3 in reaction test tubes, deoxygenate them with double row tubes, add 1.5mL of S, and dissolve them into solution M;

[0056] S3, weigh 3.61mg of BPO in the reaction test tube, use a double-row tube to deoxygenate it, add 0.5ml of S, and dissolve it into a solution R;

[0057] S4, add the solution R into the solution M, heat to 60° C., react for 36 hours, filter, dialyze the filtrate for 36 hours, and freeze-dry for 24 hours to obtain the polymer electrolyte I-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com