A polyarylether/hydrophilic resin composite diaphragm for supercapacitor and preparation method thereof

A technology of hydrophilic resin and supercapacitor, which is applied in the manufacture of hybrid capacitor separators and hybrid/electric double layer capacitors, and can solve the problem of low ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

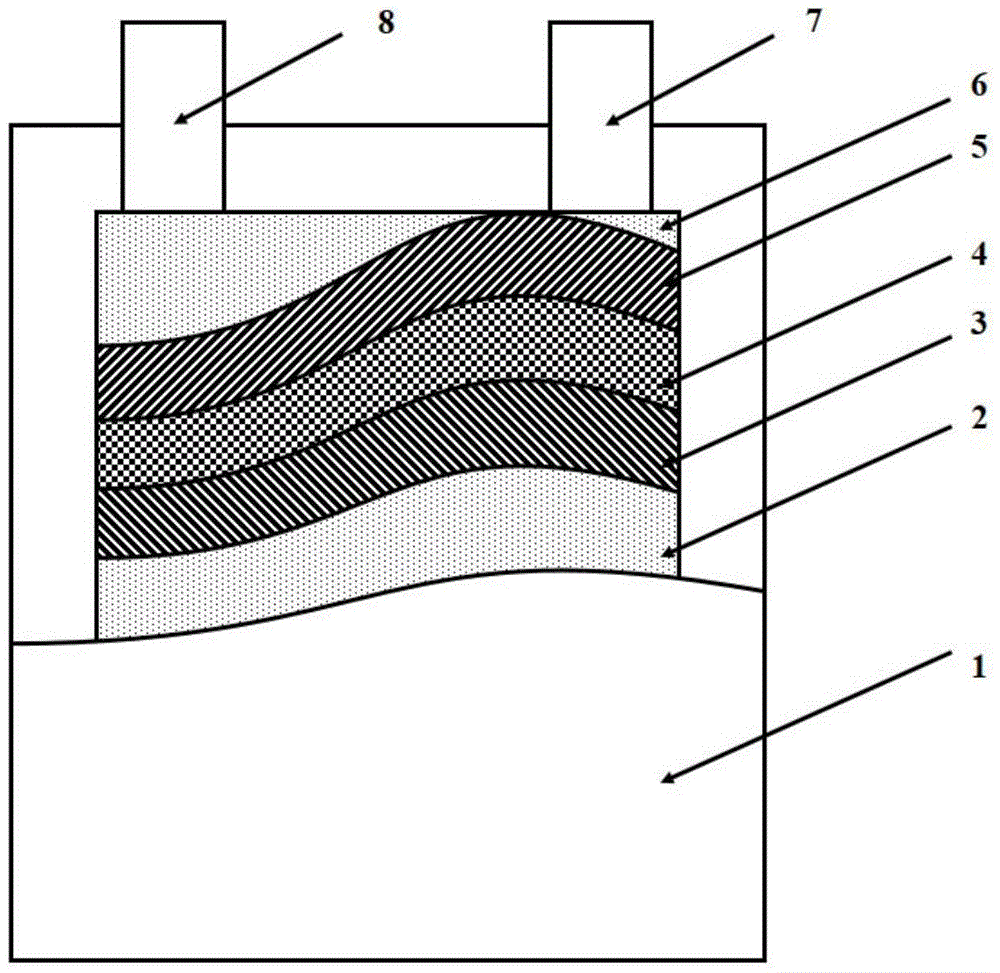

[0040] (1) Preparation of polyarylether / hydrophilic resin composite diaphragm:

[0041] Weigh 0.7500 g of bromomethyl polyarylether sulfone and place it in a 50 mL Erlenmeyer flask, add 5 mL of N,N-dimethylacetamide, and stir mechanically for 4 hours to obtain bromomethyl polyarylether sulfone solution; Put 0.2500 g of polyvinylpyrrolidone with an average molecular weight of 58,000 in a 50 mL conical flask, add 5 mL of N,N-dimethylacetamide, and stir mechanically for 4 hours to obtain a hydrophilic resin solution; The solution was mixed with the hydrophilic resin solution, mechanically stirred for 8 hours, and the two solutions were mixed evenly to obtain a mixed solution of bromomethyl polyarylether sulfone / hydrophilic resin, and the mixed solution was cast on a clean and flat glass plate surface, Dry in a vacuum oven at 60°C, 80°C, and 100°C for 8 hours, and then vacuum-dry at 120°C to obtain a bromomethyl polyarylether sulfone / hydrophilic resin composite film; bromomethyl p...

Embodiment 2

[0048] Change the mass of bromomethyl polyarylether sulfone in step (1) of Example 1 to 0.5000g, dissolve it in 5mL N,N-dimethylacetamide; the mass of polyvinylpyrrolidone with a weight average molecular weight of 58000 becomes 0.5000 g, dissolved in 5mL N,N-dimethylacetamide; the remaining steps were as described in Example 1 to obtain a stacked supercapacitor.

Embodiment 3

[0050] Change the mass of bromomethyl polyarylether sulfone in step (1) of Example 1 to 0.2500g, dissolve it in 5mL N,N-dimethylacetamide; the mass of polyvinylpyrrolidone with a weight average molecular weight of 58000 becomes 0.7500g , dissolved in 5mL N,N-dimethylacetamide; the remaining steps were as described in Example 1 to obtain a stacked supercapacitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com