Porous carbon material based on high-temperature thermal shock carbonization and KOH activation of coconut shell material, preparation method and application

A technology of porous carbon materials and coconut shell materials, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of low efficiency and hindering development of electrochemical electrode materials, and achieve rich pores, narrow pore size distribution, The effect of high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

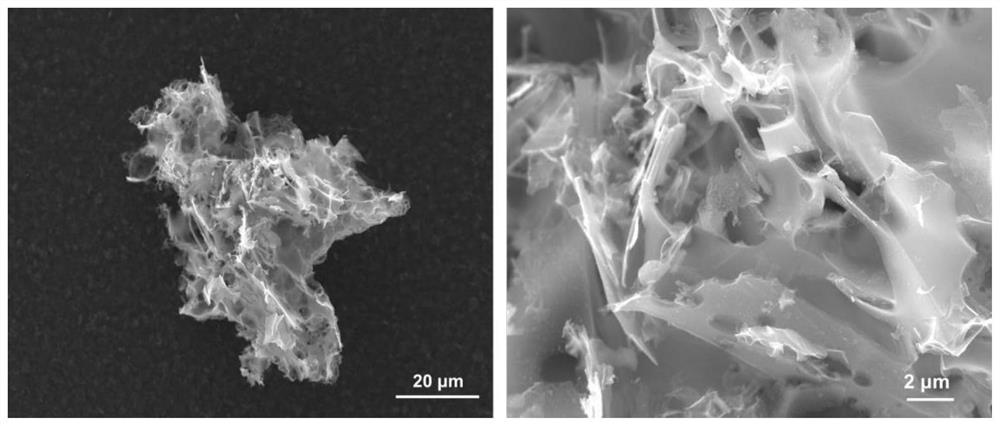

[0034] (1) Cut the purchased dried coconut husk into finely divided pieces, and manually grind it in a mortar for 1 hour until the material is ground into particles with a diameter of 50-100 μm and a higher degree of uniformity.

[0035] (2) Utilize the ball mill to continue to grind the coconut shell particles (using the agate ball mill jar), the grinding time is set to 10h, and the rotating speed is set to 300r / min, finally the coconut shell powder with a particle diameter of 5 μm can be obtained.

[0036] (3) The first step of HT treatment is carried out on the obtained coconut shell powder (heat shock temperature is 800°C), the specific process is as follows: the treated carbon cloth with a size of 1*1.5cm is glued to two pieces of glass through conductive glue The copper foils on the boards are connected on the narrow side (there is a 1cm wide gap between the two glass plates, and the coconut shell powder is evenly coated on the carbon cloth), and the coconut shell powder ...

Embodiment 2

[0039] (1) Cut the purchased dried coconut husk into finely divided pieces, and manually grind it in a mortar for 1 hour until the material is ground into particles with a diameter of 50-100 μm and a higher degree of uniformity.

[0040] (2) Utilize the ball mill to continue to grind the coconut shell particles (using agate-made ball milling tank), the grinding time is set to 10h, and the rotating speed is set to 300r / min, and finally the coconut shell powder with a particle diameter of 20 μm can be obtained.

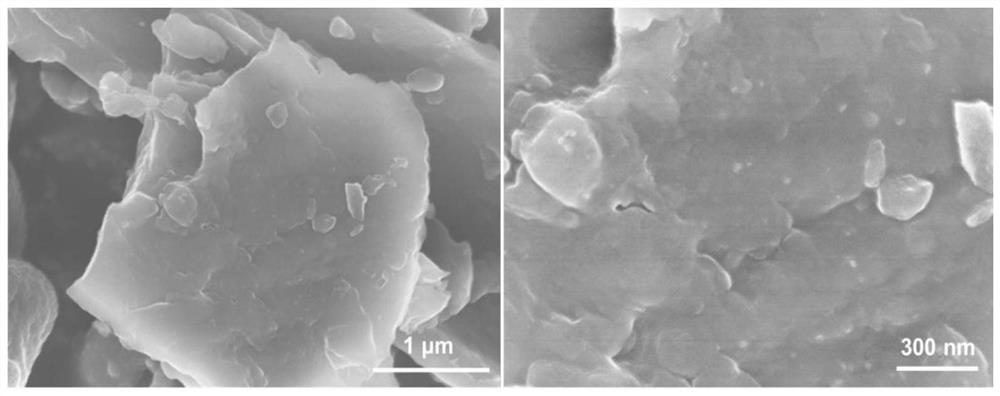

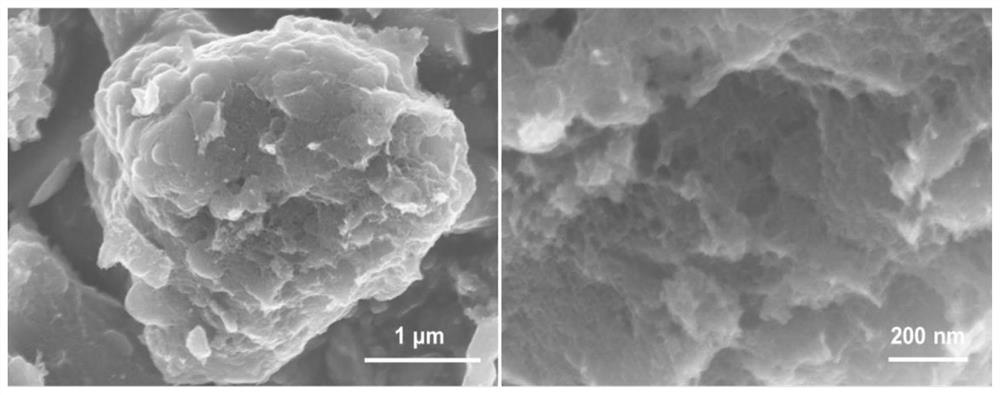

[0041] (3) The first step of HT treatment is carried out on the obtained coconut shell powder (the thermal shock temperature is 900 ° C). The surface of the coconut shell material after one HT process is smooth and there are no obvious pores, indicating that one HT process cannot treat coconut shells. The shell powder is effectively carbonized and activated.

[0042] (4) Weigh 1 mg of coconut shell pre-carbonized powder completed by high-temperature thermal shock carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com