Micro alloying SWRH87B hot rolled wire rod and manufacturing method thereof

A technology of hot-rolled wire rod and micro-alloying, which is applied in the field of hot-rolled wire rod to achieve the effect of remarkable benefit, good quality and good use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

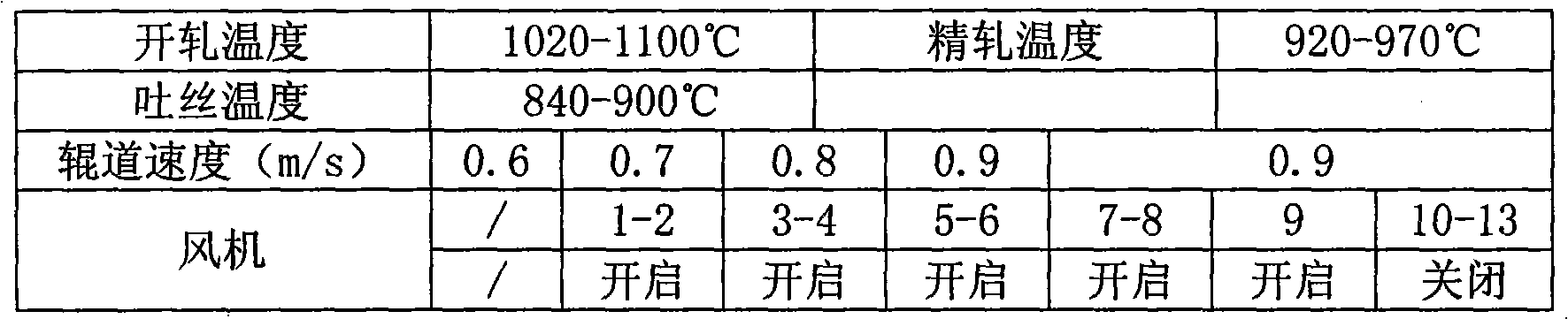

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: furnace number 8B05481

[0033] Converter smelting, adding 179 tons of molten iron as raw material, 20.2 tons of pig iron for steelmaking, 4.5 tons of scrap steel, and working oxygen pressure of 7kg / cm for oxygen supply 2 , oxygen supply time 13 minutes and 35 seconds; lime addition 7900kg, light burnt dolomite 1664kg; Austrian ore 1761kg; endpoint carbon: 0.45%, phosphorus: 0.013%; tapping temperature 1613°C.

[0034] Deoxidation alloying, silicon calcium barium 300kg, silicon manganese 880kg, ferromanganese 1000kg, carbon ferrochrome 950kg.

[0035] For LF refining furnace, the flow rate of argon gas in the early stage is 510NL / min, the flow rate in the middle stage is 300NL / min, the flow rate of argon gas in the later stage is 100NL / min, the synthetic slag is added 600kg, the submerged arc slag is 300kg, and the outbound oxygen activity is 5.7ppm.

[0036] The tundish temperature is 1485°C, the crystallizer water volume is 1657L / min, and the casting sp...

Embodiment 2

[0038] Embodiment 2: furnace number 8A04945

[0039] Converter smelting, adding 117 tons of molten iron as raw material, 20.9 tons of pig iron for steelmaking, 4.7 tons of scrap steel, and working oxygen pressure of 7.5kg / cm for oxygen supply 2 , The oxygen supply time is 11 minutes and 33 seconds. The amount of lime added is 13980kg, lightly burned dolomite is 240kg; Austrian ore is 4.28kg; endpoint carbon: 0.52%, phosphorus: 0.013%; tapping temperature is 1590°C.

[0040] Deoxidation alloying, silicon calcium barium 300kg, silicon manganese 900kg, ferromanganese 1000kg, carbon ferrochrome 1000kg.

[0041] For LF refining furnace, the flow rate of argon gas in the early stage is 490NL / min, the flow rate in the middle stage is 330NL / min, the flow rate of argon gas in the later stage is 30NL / min, the synthetic slag is added 600kg, the submerged arc slag is 300kg, and the outbound oxygen activity is 9ppm.

[0042] The tundish temperature is 1480°C, the crystallizer water volum...

Embodiment 3

[0044] Embodiment 3: furnace number 8B05468

[0045] Converter smelting, adding 176 tons of molten iron as raw material, 15.3 tons of pig iron for steelmaking, 20.6 tons of scrap steel, and working oxygen pressure of 7kg / cm for oxygen supply 2 , The oxygen supply time is 12 minutes and 23 seconds. The amount of lime added is 12600kg, lightly burned dolomite is 330kg; Austrian ore is 3070kg; endpoint carbon: 0.57%, phosphorus: 0.01%; tapping temperature is 1600°C.

[0046] Deoxidation alloying, silicon calcium barium 330kg, silicon manganese 920kg, ferromanganese 1550kg, carbon ferrochrome 1000kg.

[0047] For LF refining furnace, the flow rate of argon gas in the early stage is 520NL / min, the flow rate in the middle stage is 330NL / min, the flow rate of argon gas in the later stage is 90NL / min, the synthetic slag is added 600kg, the submerged arc slag is 300kg, and the outbound oxygen activity is 12ppm.

[0048] The tundish temperature is 1479°C, the crystallizer water volume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com