Low-nitrogen ferrotitanium, its manufacturing method and cored wire

A manufacturing method and technology of cored wire, applied to the manufacturing method and the field of ferro-titanium-containing wire and ferro-titanium alloy, can solve the problem of reduced plasticity and impact toughness, decreased impact toughness, and difficulty in meeting the requirements of manufacturing high-strength and high-corrosion resistance Performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1 The manufacture method of the low nitrogen ferro-titanium of the present invention

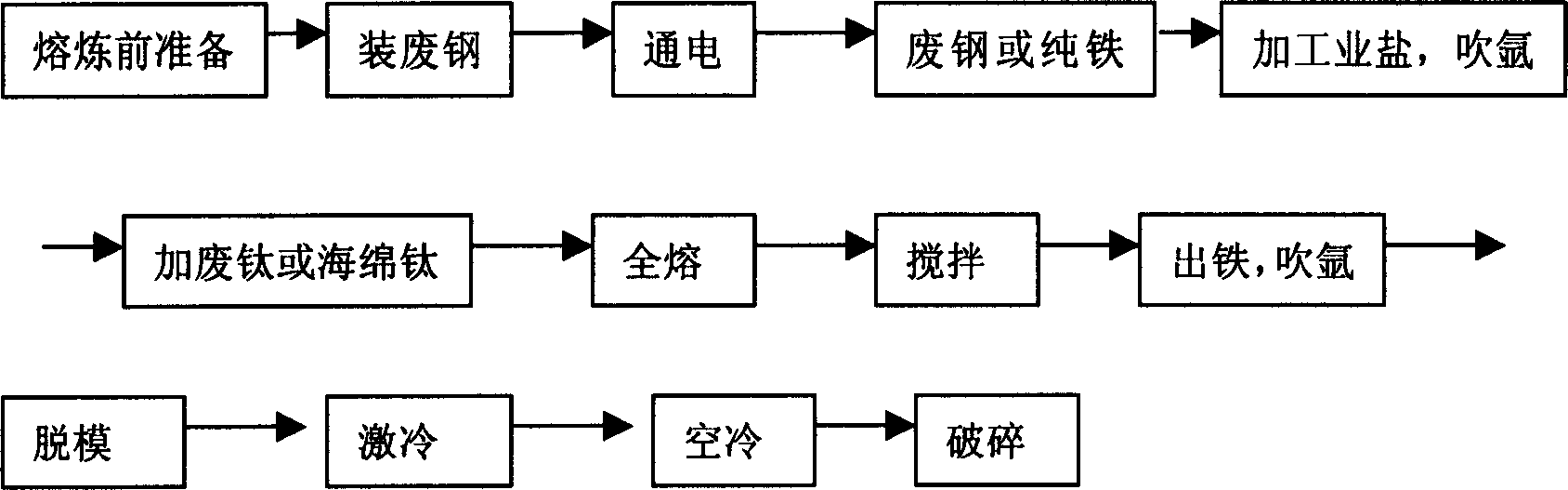

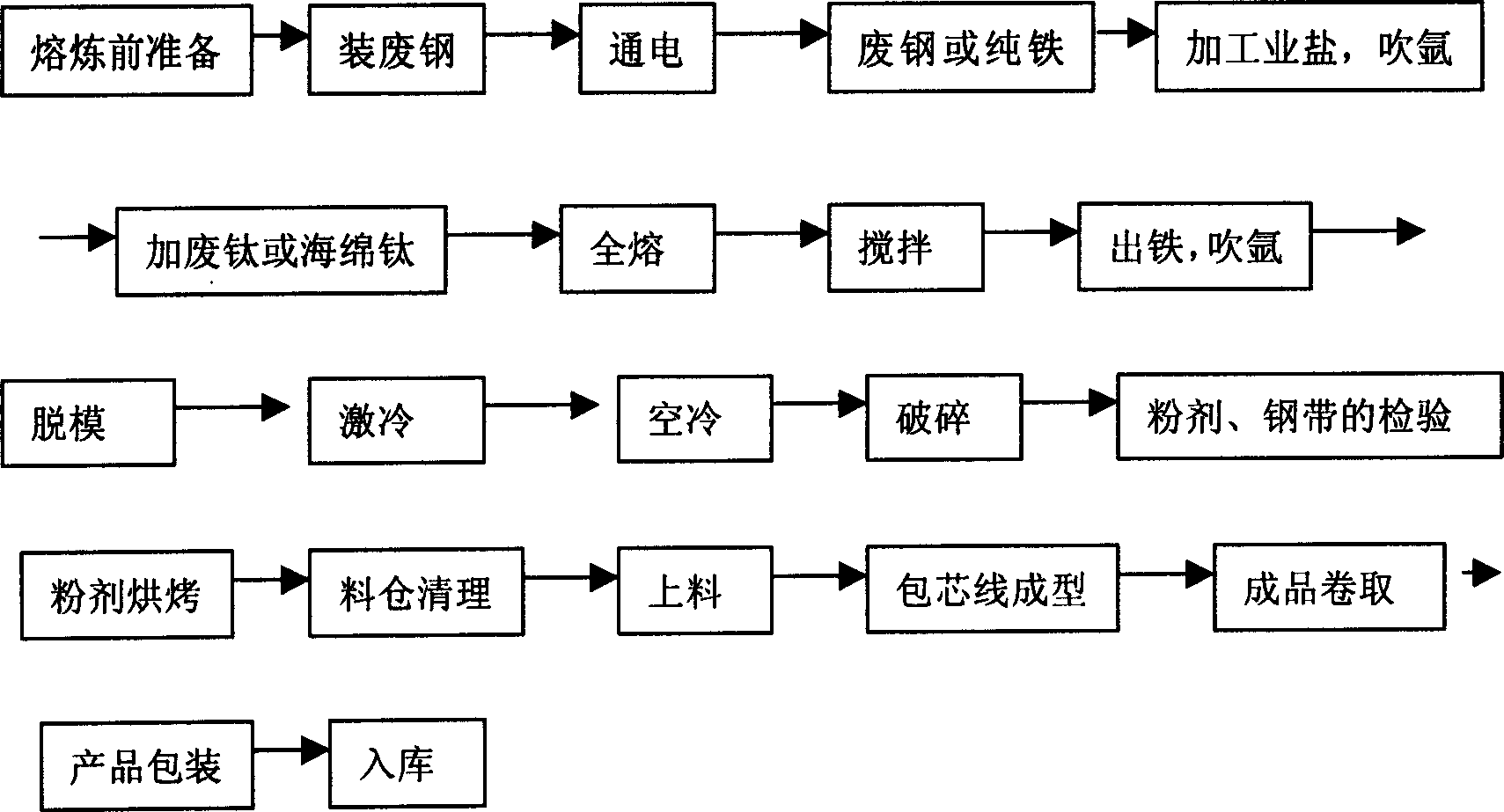

[0064] 1. Process flow such as figure 1 shown.

[0065] 2. Equipment

[0066] Intermediate frequency furnace, magnesia furnace lining, induction coil, metal crucible mold, power supply system and water cooling system, jaw crusher and double roller machine.

[0067] 3. Raw materials

[0068] (1) Sponge titanium, waste titanium, high-quality scrap steel or pure iron with low content of impurity elements such as nitrogen, aluminum, silicon, carbon, phosphorus and sulfur are used as the main raw materials.

[0069] (2) Auxiliary materials, industrial salt (NaCl) with a low melting point (776°C) is used as a slagging agent in smelting, and argon is used as a protective gas.

[0070] 4. Preparatory process before smelting

[0071] (1) Furnace lining is knotted with fused magnesia (DMS-98), and its raw material ratio is shown in Table 1 below.

[0072] Material

...

Embodiment 2

[0115] Embodiment 2 The manufacturing method of the cored wire using the low-nitrogen ferrotitanium of the present invention

[0116] Artificially crush the cooled low-nitrogen ferrotitanium to particles of about 60mm, and then use a jaw crusher to crush it to 20-60mm, and then use a roller machine to continue crushing the 20-60mm ferrotitanium block to a particle size of less than 2mm. pink. At this time, the nitrogen content of the low-silicon ferro-titanium is ≤0.15% by weight, and the content of the aluminum is <3% by weight; then, the low-nitrogen ferro-titanium powder is rolled into Wind into a cored wire.

[0117] According to the manufacturing method of the low-silicon ferro-titanium cored wire of the present invention, the core-spun strip used by the low-nitrogen ferro-titanium cored wire is a high-quality carbon structural steel of the national standard GB699-88 type, and its composition is as follows:

[0118] C 0.05-0.12%, Si≤0.17-0.37%, Mn≤0.35%, S≤0.035%, P≤0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com