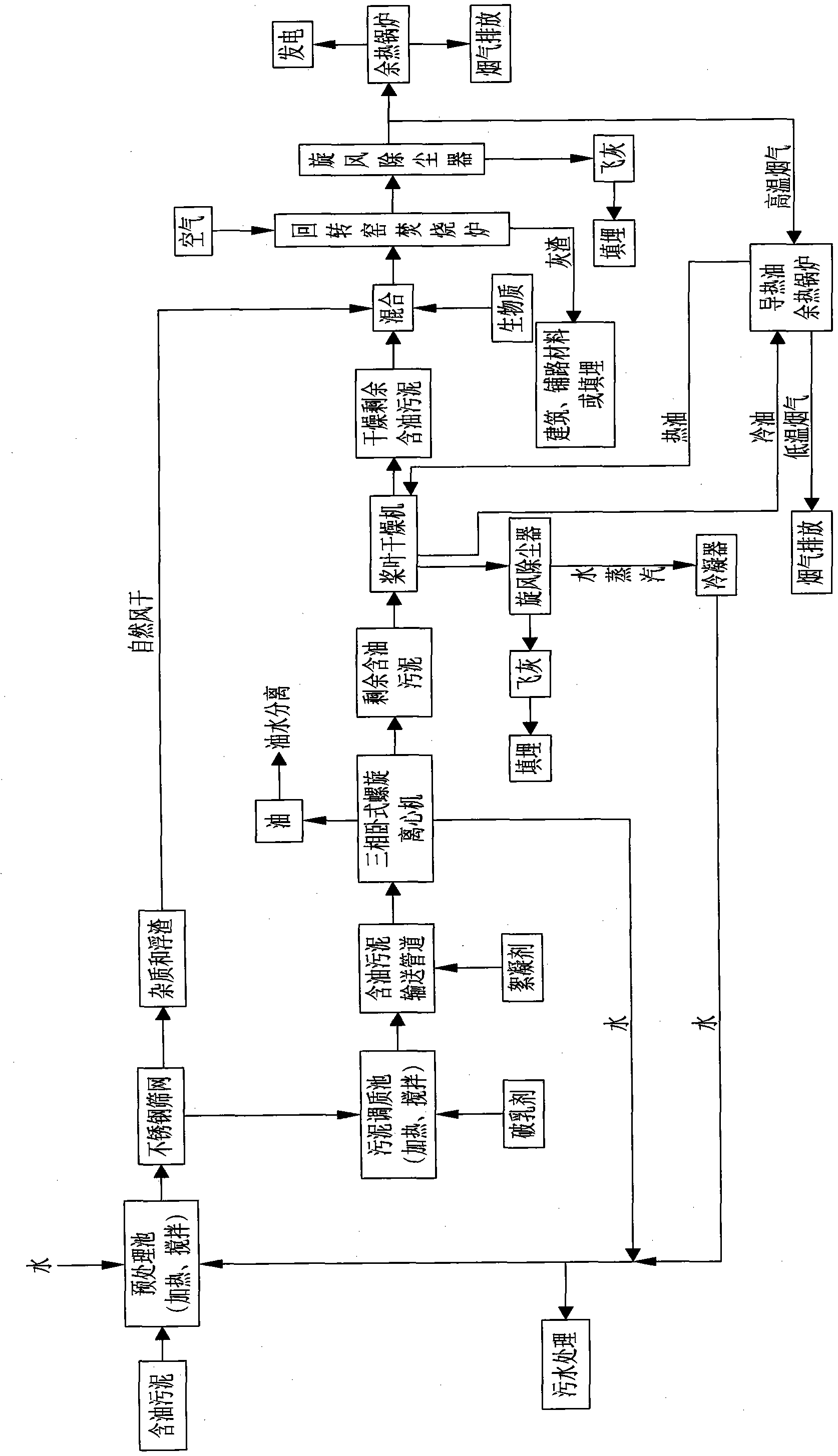

Oily sludge recycling and innocent comprehensive treatment process

A comprehensive treatment and oil sludge technology, applied in the field of resources and environment, can solve the problems of low investment, long treatment process and high treatment cost of coking method, and achieve good resource utilization effect, elimination of secondary pollution and good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add the same volume of water and oily sludge into the oily sludge pretreatment tank at the same time, heat the temperature of the mixed liquid to 45°C, the stirring intensity of the agitator is 450r / min, and the stirring time is 45min, so that the oily sludge becomes fluidized sewage mud. The fluidized sludge is input into the stainless steel screen by the mud pump, and the solid impurities and scum with a particle size larger than 5mm are filtered out, and the fluidized sludge passing through the stainless steel screen enters the oily sludge conditioning tank, and the large pieces are removed The solid impurities and scum are air-dried under natural conditions to make the moisture content reach 30-45%. Add a mixture of two demulsifiers, sodium dodecylbenzenesulfonate and polyoxyethylene lauryl ether, into the oily sludge conditioning tank through a dosing device. The tempering temperature is 65-80°C, the stirring intensity is 400r / min, and the stirring time is 45min. ...

Embodiment 2

[0036] The fluidization and sieving pretreatment of oily sludge is the same as in Example 1. A mixture of two demulsifiers, sodium carbonate and sodium sulfate, is added to the oily sludge conditioning tank through a dosing device, and the addition amount is 0.02% of the weight of the oily sludge. %, using electric heating to keep the tempering temperature at 65-80°C, the stirring intensity at 400r / min, and the stirring time at 50min. The oily sludge treated by demulsification is transported to the oily sludge delivery pipeline, and the flocculant copolymerized cationic polyacrylamide is added into the pipeline through the dosing device, and the amount of the flocculant added is 0.2% of the weight of the oily sludge. The oily sludge after flocculation is transported to a three-phase horizontal screw centrifuge for three-phase separation of oil, water and mud, and the separated oil enters the oil-water separation system to recover crude oil, and the oil recovery rate can reach a...

Embodiment 3

[0039] Add water and oily sludge to the oily sludge pretreatment tank at the same time, the volume ratio is 2:1, the temperature of the mixed solution is heated to 45°C, the stirring intensity of the agitator is 500r / min, and the stirring time is 40min, so that the oily sludge Mud becomes fluidized sludge. The fluidized sludge is input into the stainless steel screen by the mud pump, and the solid impurities and scum with a particle size larger than 5mm are filtered out, and the fluidized sludge passing through the stainless steel screen enters the oily sludge conditioning tank, and the large pieces are removed The solid impurities and scum are air-dried under natural conditions to make the moisture content reach 30-45%. Add a mixture of two demulsifiers, sodium dodecylbenzenesulfonate and polyoxyethylene lauryl ether, into the oily sludge conditioning tank through a dosing device. The tempering temperature is 65-80°C, the stirring intensity is 400r / min, and the stirring time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com