Production method of bright stock

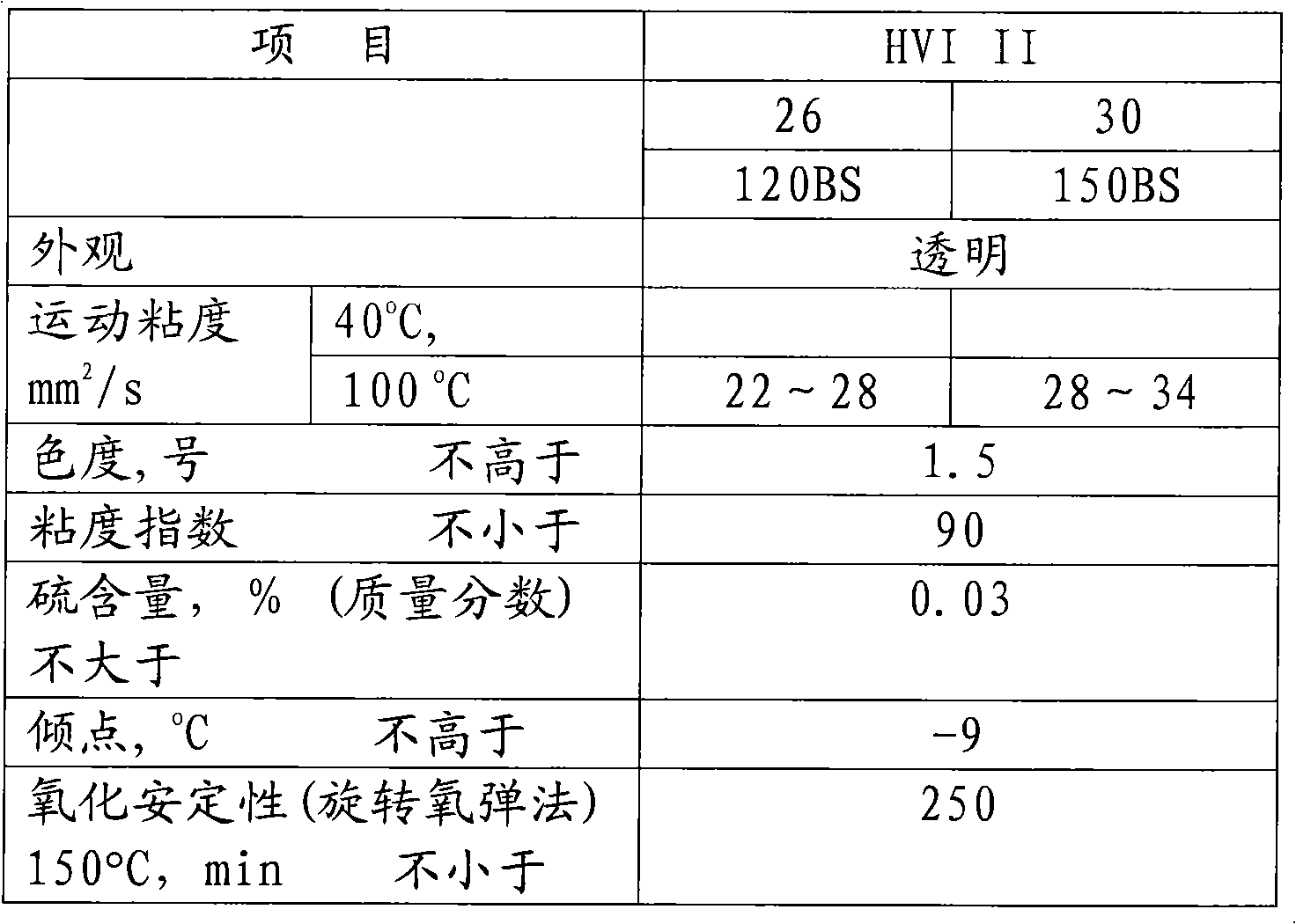

A production method and bright stock technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of low output of light deasphalted oil and limitation of bright stock production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

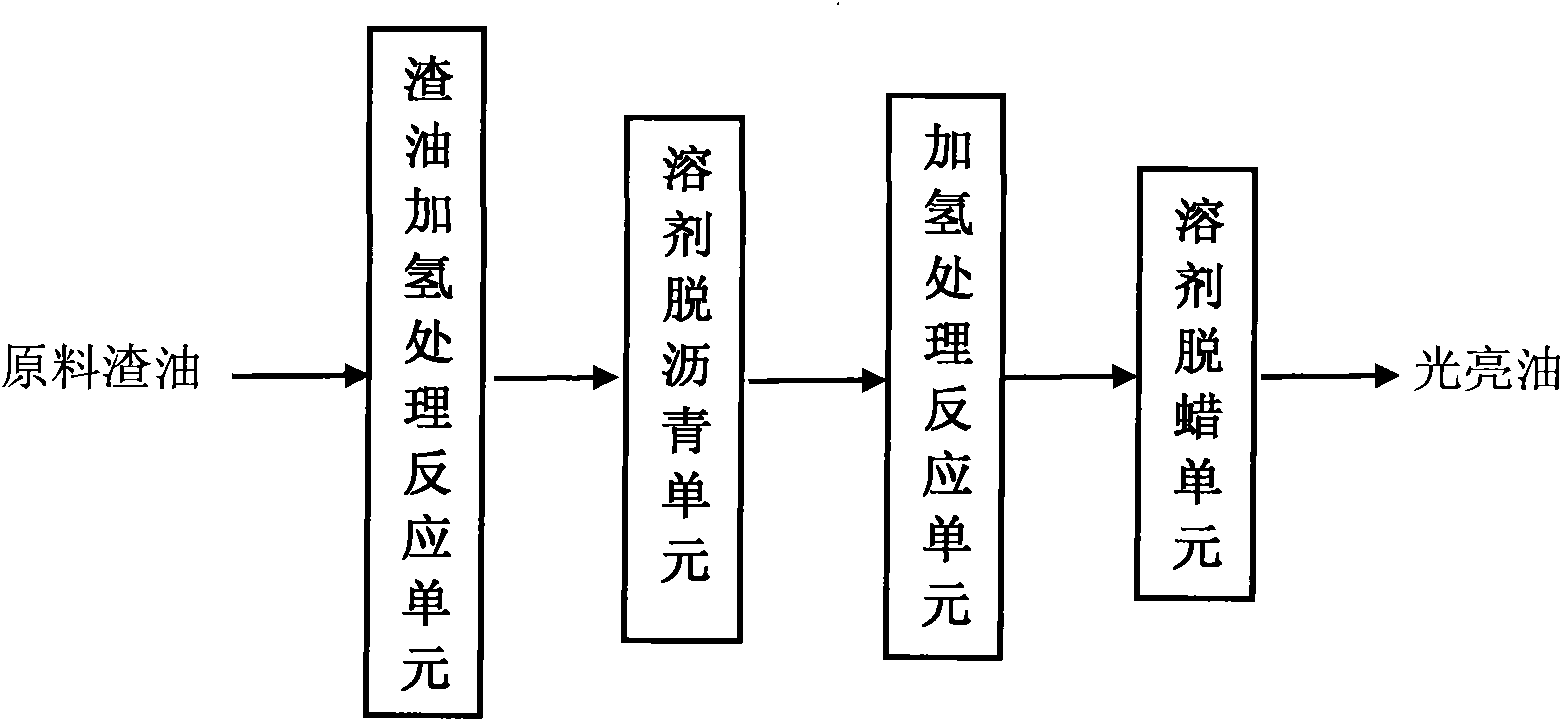

[0064] according to figure 1 The process shown produces bright stock. The residue raw material is a vacuum tower bottom oil whose properties are listed in Table 1.

[0065] Residue Hydrotreating Reaction Unit Operation:

[0066] Residuum hydrogenation process is carried out according to the method disclosed in CN101210200, adopts two reactors, one reversely loads hydrogenation protecting agent and hydrodemetallization agent, and adorns hydrodesulfurization catalyst in the second reactor, three ratio (volume ratio ) is 5:45:50, and the commercial brands of hydrogenation protection agent, hydrodemetallization agent, and hydrodesulfurization agent are RG-10A, RDM-2, and RMS-1, all of which are provided by Changling, a Sinopec Catalyst Branch Company. Catalyst factory production. The reaction conditions of residual oil hydrotreating, >520°C hydrogenated residual oil column bottoms yield (based on residual oil feed), and properties are listed in Table 2.

[0067] Solvent deasph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com