Embedded waxing and polishing machine for vehicles

A waxing polishing, embedded technology, used in vehicle maintenance, vehicle maintenance/repair, vehicle exterior cleaning devices, etc., can solve the problems of high polishing labor intensity, the nozzle touches the body, and the polishing effect is poor, and achieves a good polishing effect. , The body is light and the effect of high work intensity is solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

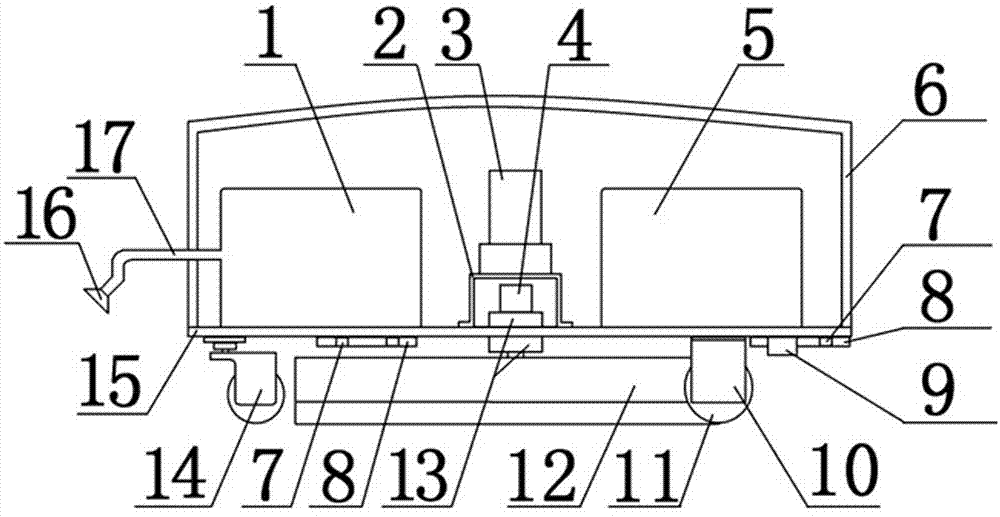

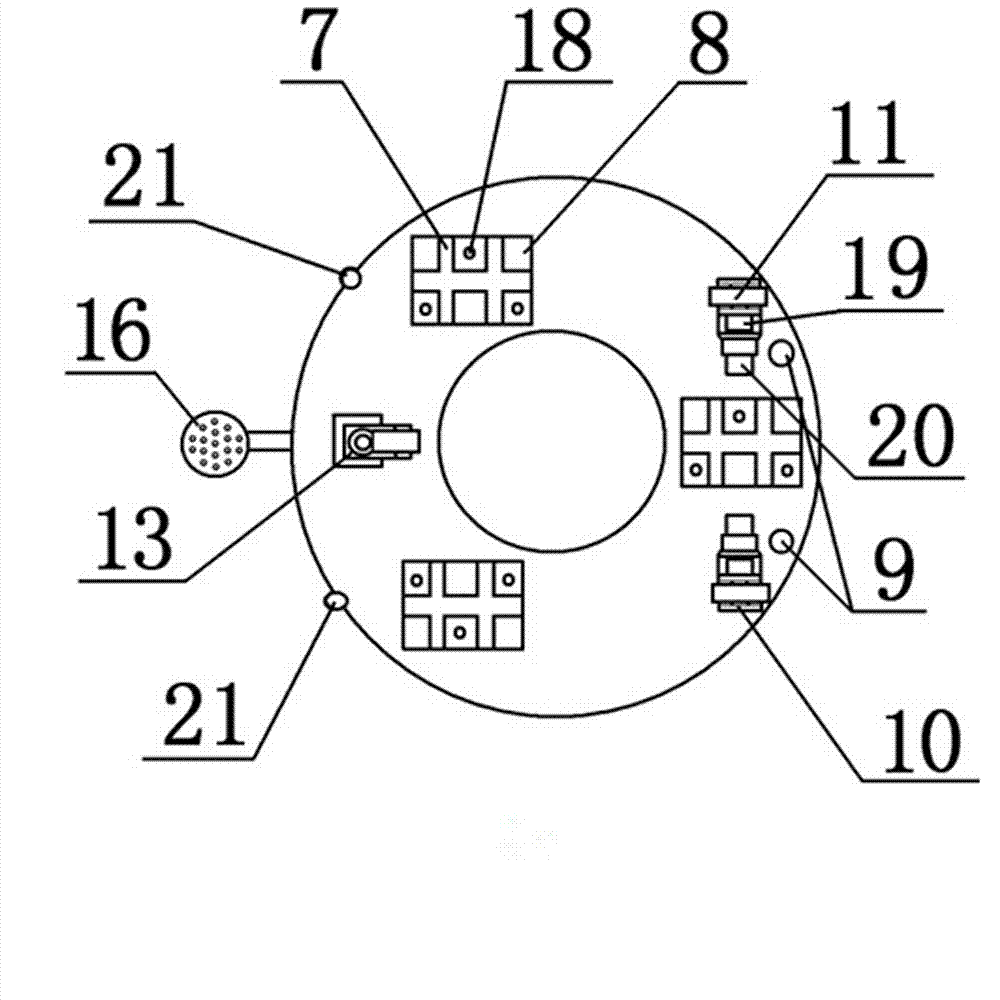

[0019] Referring to the accompanying drawings, an embedded vehicle waxing and polishing machine includes a liquid wax storage bin 1, a liquid wax sprayer 16, a liquid wax pipeline 17, a brush motor frame 2, a brush motor 3, and a brush drive shaft 4, Brush plate bearing seat 13, brush plate 12, control box 5, shell 6, chassis 15, permanent magnet 7, yoke iron 8, adjustment bolt 18, effect detection sensor 9, wheel frame 10, driving wheel 11, universal wheel 14, Infrared sensor 21, travel motor 20, travel motor shaft 19.

[0020] The liquid wax storage bin 1 is installed in the front part of the shell 6 and is connected with the liquid wax sprayer 16 through the liquid wax pipeline 17 .

[0021] The brush disc motor 3 is fixed on the chassis 15 through the brush disc motor frame 2, the brush disc 12 and the brush disc motor 3 are connected to each other through the brush disc bearing seat 13 and the brush disc drive shaft 4, and the brush disc 12 is driven by the brush disc mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com