Automatic waxing device and method

A technology for grinding and supplying wax, which is applied in vehicle exterior cleaning devices, devices for coating liquid on the surface, transportation and packaging, etc. It can solve problems such as failure to achieve market commercialization, high device complexity, and huge installation space. Achieve the effect of saving manpower expenditure, reducing complexity and saving volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

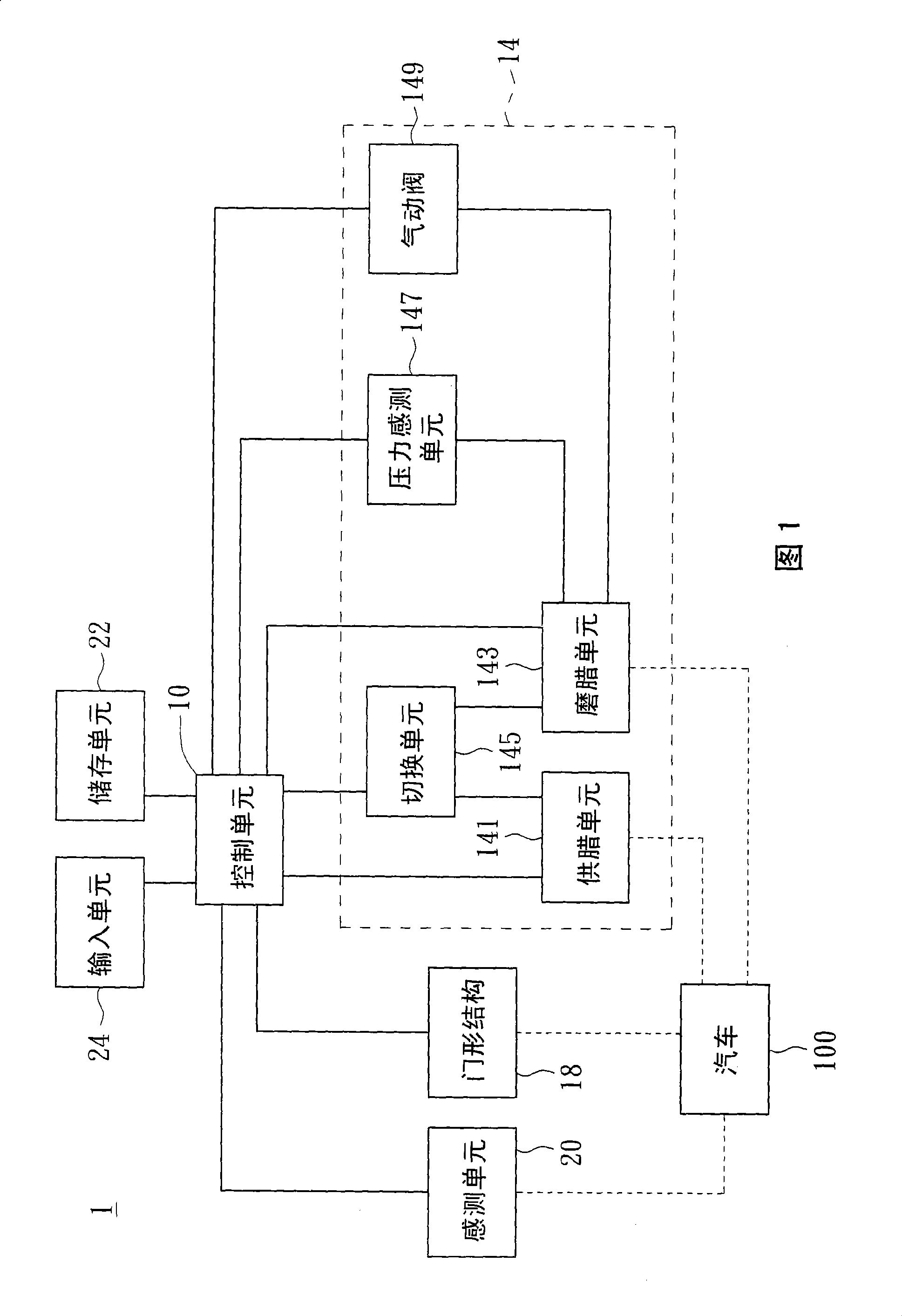

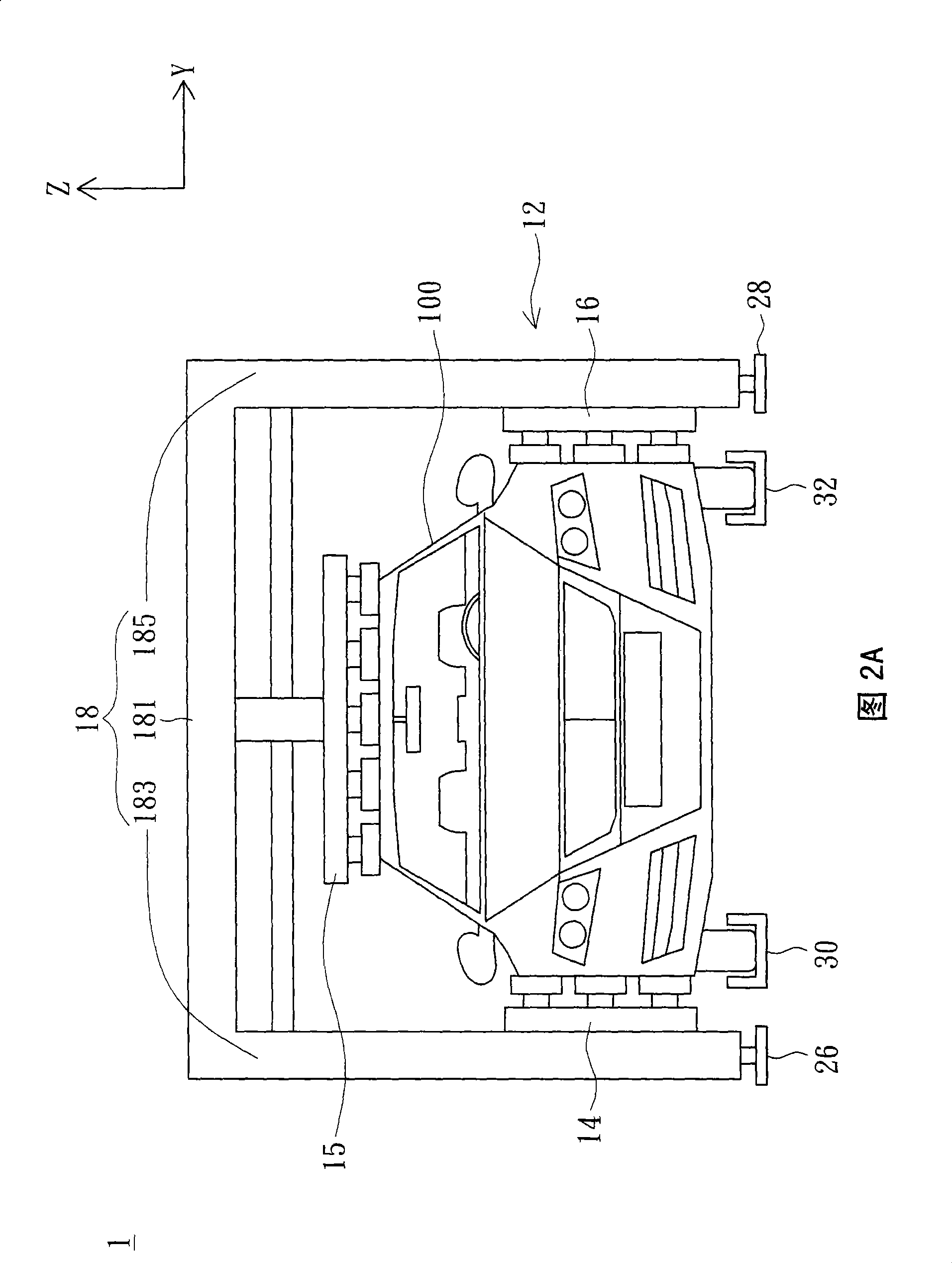

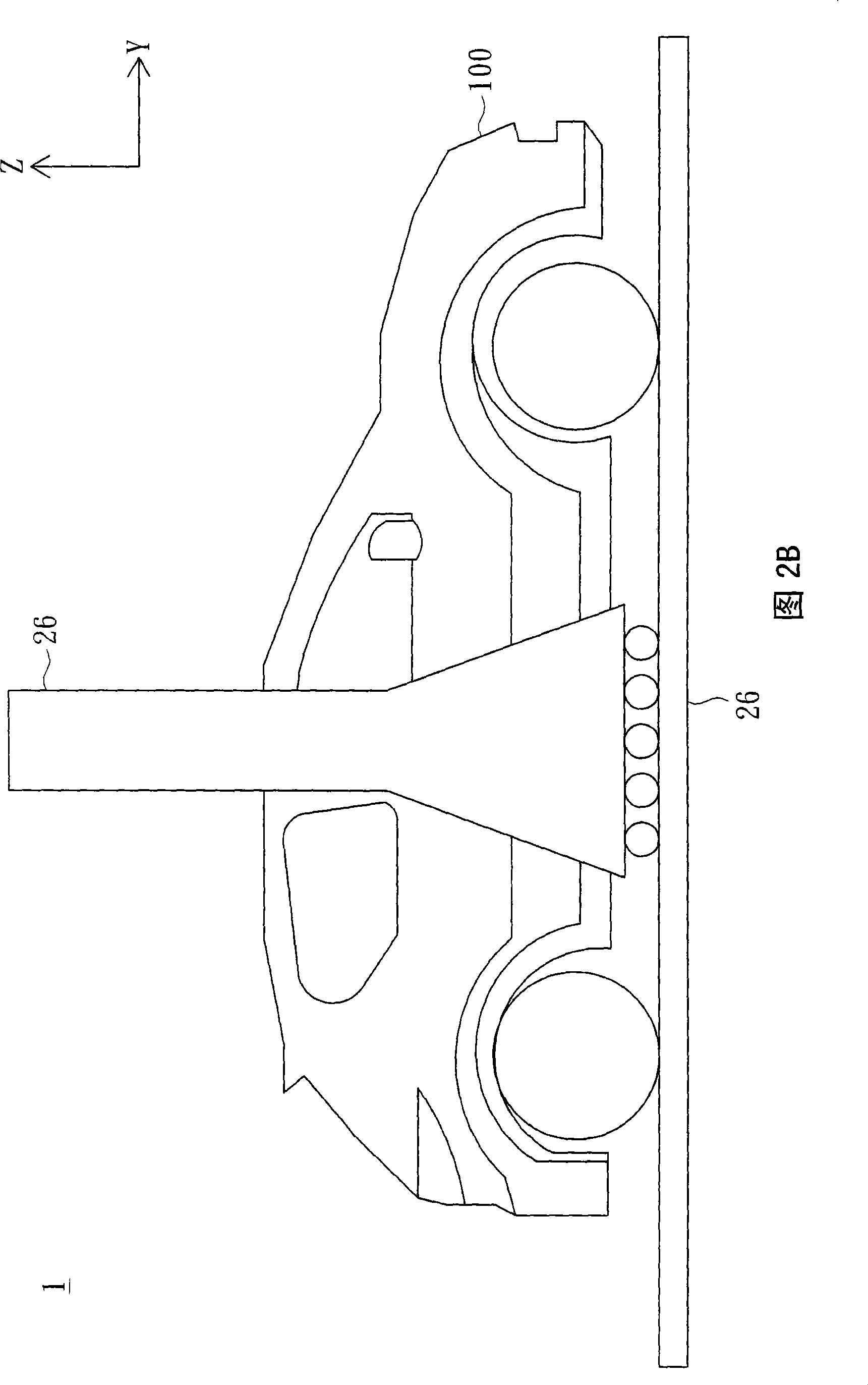

[0107] The automatic waxing device of the present invention includes a movable door-shaped module, at least one waxing module and a control module. The mobile gantry module includes a gantry structure that is movable relative to the vehicle. The waxing module is arranged on the gate structure, and the waxing module includes a wax supply unit and a wax grinding unit. The control module is coupled to the gate structure, the wax supply unit and the wax grinding unit. Wherein, the control module determines a moving stroke of the gate structure relative to the automobile, a waxing stroke of the wax supply unit on the automobile, and a waxing stroke of the wax grinding unit on the automobile according to the data of the automobile.

[0108] The automatic waxing method of the present invention includes inputting data of a car to a waxing device; determining a waxing program of the car according to the data of the car; and, performing the waxing device relative to the waxing program ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com