Method of measuring silicon content in nitrogen-manganese alloy

A technology of nitrogen-manganese alloy and silicon content, which is applied in the field of instrument analysis, can solve the problems of long cycle time and cumbersome operation, and achieve the effects of low detection limit, shortened operation process, and reduced labor expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

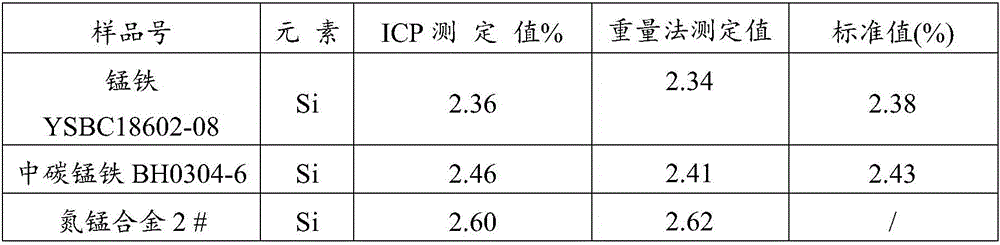

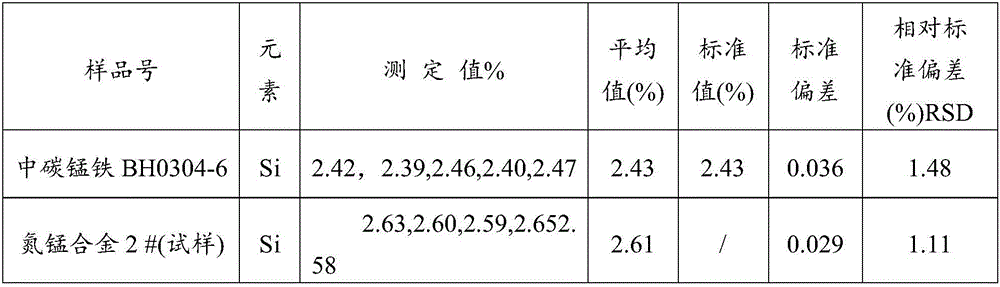

[0046] Plasma emission spectrometer adopts ICP-AES: produced by American PE company, OPTIMA5300DV two-way observation type full-spectrum direct-reading plasma spectrometer, solid-state detector (CCD), wavelength range 190-780nm, echelle grating, jewel cross nebulizer, SCOTTON Fog chamber, swirling flow chamber for high content, winXP computer operating system, Winlab32 software, working parameters are shown in Table 1. The measurement wavelength of silicon is: 251.612nm.

[0047] Table 1 ICP-AES instrument working condition parameter list

[0048] parameter high frequency power Cooling air flow Auxiliary air flow Carrier gas flow Solution lift value 40.68MHZ 1300W 15L / min 0.2L / min 0.8L / min 1.5mL / min parameter rinse time Pre-burn time Integration time Reading delay observation height Observation method value 8s 45s 2~10s automatically 30s 15mm radial or axial

[0049] 1. Draw the calibration curve;

[0050...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com