Feeding device for automatic shaft-riveting of transmission chain

A feeding device and transmission chain technology, applied in the direction of metal chains, etc., can solve the problems of low processing precision, low processing efficiency, and increased costs of the chain, and achieve the effects of reducing labor expenditure, improving efficiency, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

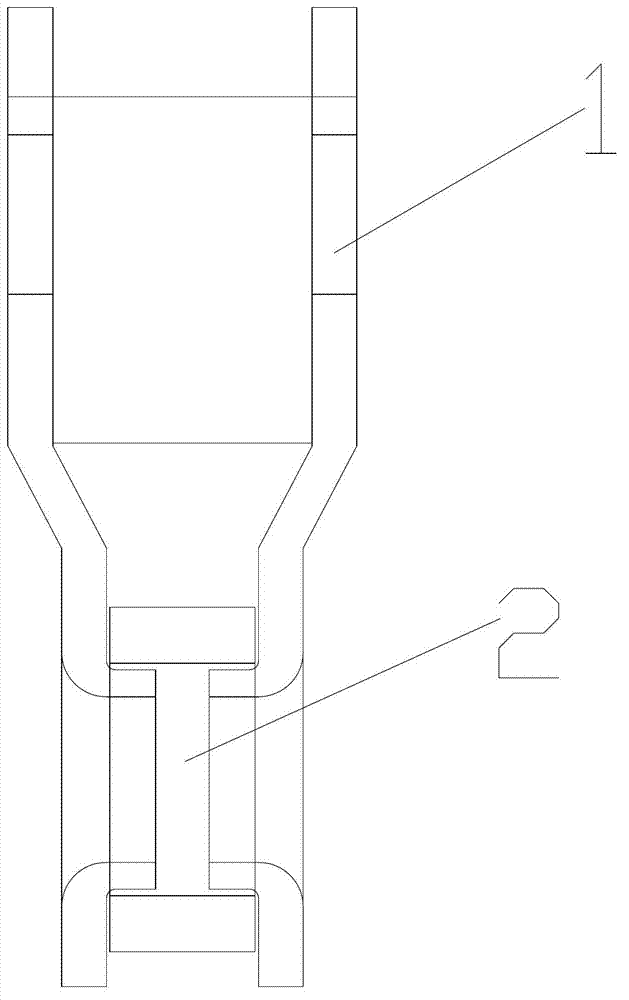

[0015] as attached figure 1 The shown schematic diagram of the chain structure of the present invention is mainly composed of a chain piece 1 and a chain shaft 2, and the chain piece is riveted together by turning over the chain shaft.

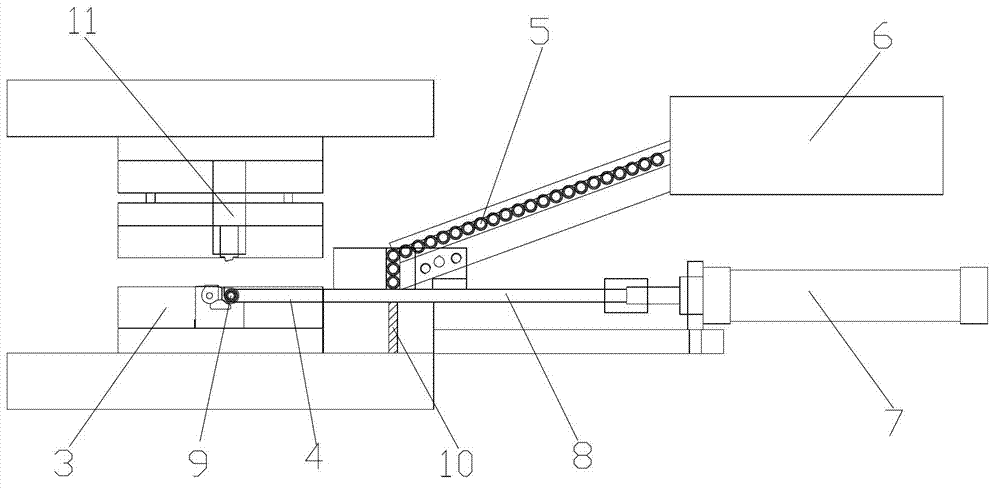

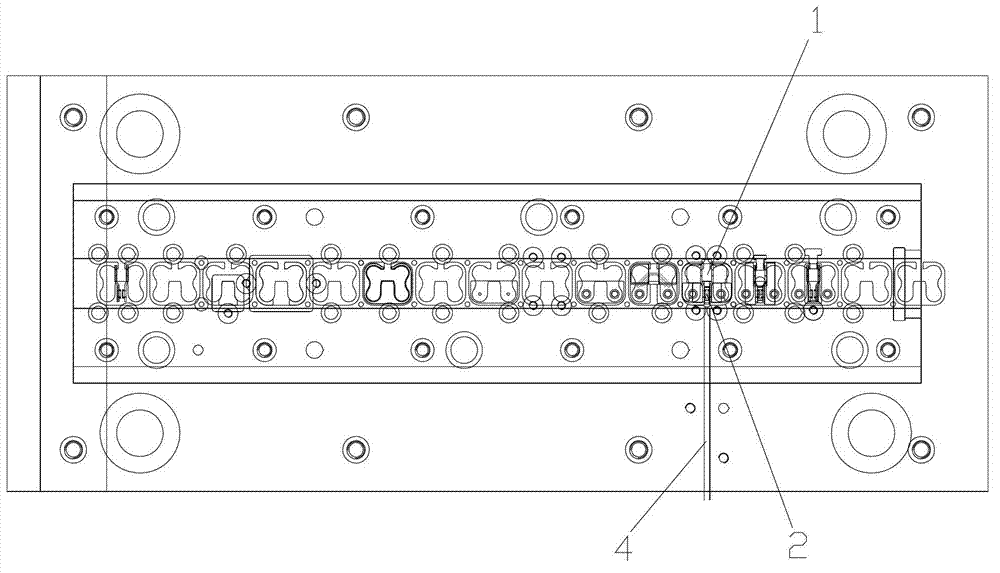

[0016] attached figure 2 , 3 It is a transmission chain automatic riveting shaft feeding device according to the present invention, which includes a chain forming die 3, on which the product material to be processed is placed, and the product material is processed step by step, and the product material is turned 90° A chain shaft introduction groove 4 is provided at the folding place; a material guide groove 5 is arranged obliquely above the 4 ends of the chain shaft introduction groove, and the discharge port of the material guide groove 5 is located directly above the chain shaft introduction groove 4, and the material guide groove The feeding end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com