Method for producing paster type antenna

A manufacturing method and antenna technology, applied in the direction of antenna, antenna components, radiating element structure, etc., can solve problems such as unfavorable competition, price Anger, separation of copper and Mylar, etc., to reduce labor costs and increase stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

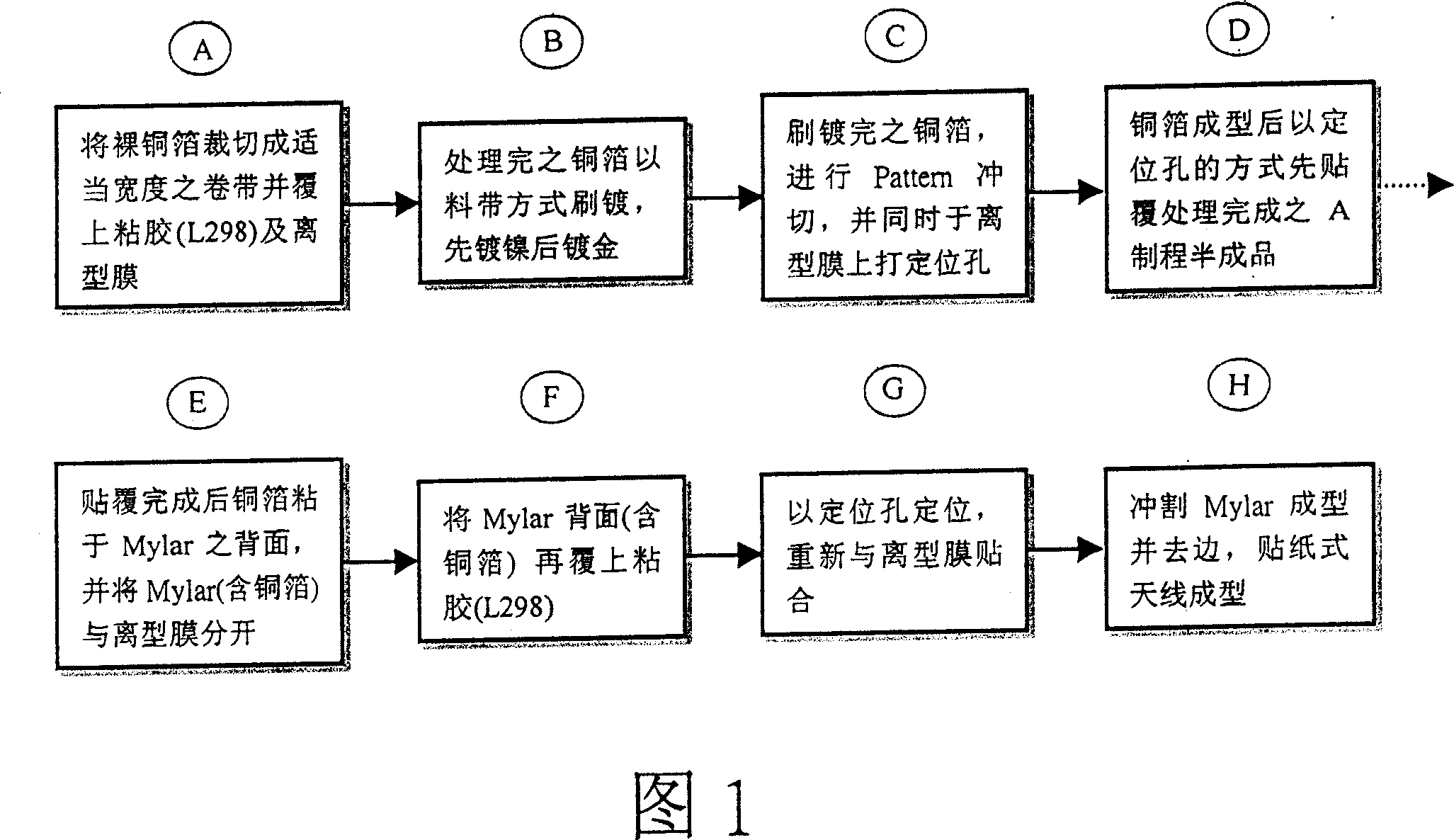

[0019] See also Fig. 1, the manufacturing method flowchart of the present invention, its step comprises:

[0020] a. Cut the bare copper foil into tapes of appropriate width and cover with adhesive and release film;

[0021] b. The treated copper foil is brush-plated in the form of strips, first nickel-plated and then gold-plated;

[0022] c. Brush the plated copper foil, punch the shape (Pattern), and punch positioning holes on the release film at the same time;

[0023] d. After the copper foil is formed, the Mylar semi-finished product with glue is first pasted by the way of positioning holes;

[0024] e. After the cladding is completed, the copper foil is adhered to the back of Mylar, and the Mylar (containing copper foil) is separated from the release film;

[0025] f. Cover the back of Mylar (including copper foil) with adhesive;

[0026] g. Locate with the positioning hole and reattach to the release film; and

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com