Wax screen printing processing method for cloth-based microfluidic analytical chip

A technology for microfluidic analysis and processing methods, which is applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc. Analyze the problems of chips, difficult high-throughput, high-resolution chip processing, etc., to achieve the effects of simple instrument operation, high resolution, and high utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A wax screen printing processing method for a cloth-based microfluidic analysis chip (there are 3 shapes in the hydrophilic region), comprising the following steps:

[0043] 1) Take about 0.8 square meters of cotton cloth and put it in a beaker, add 500mL of ultrapure water, and then boil it in a water bath at a temperature of 95°C for 5 minutes;

[0044] 2) Take out the cotton cloth after boiling, put the cotton cloth in another beaker after the water drips dry, add 500mL of sodium carbonate solution with a concentration of 10mg / mL, and soak for 5min;

[0045] 3) After soaking in sodium carbonate solution, rinse with water until the pH value of the cotton cloth is 6, and dry at room temperature for 2 hours; the normal pH value of human urine is about 6, which is weakly acidic. Rinsing until the pH value of the cotton cloth is 6 is to ensure that there will be no great interference in the later biochemical detection.

[0046] 4) The treated cotton cloth is laid flat on...

Embodiment 2

[0050] Wax screen printing processing method for high-throughput cloth-based microfluidic analysis chips

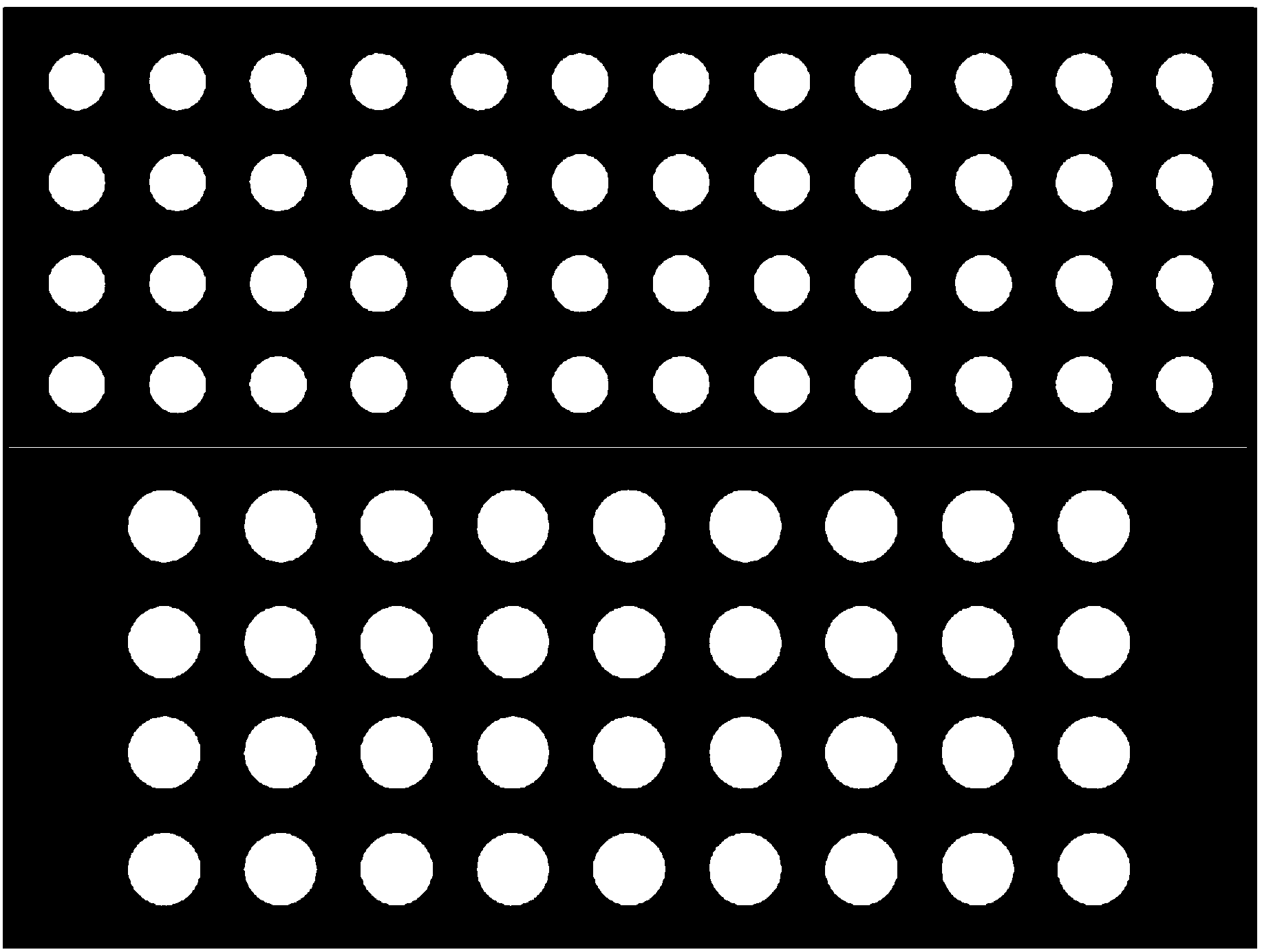

[0051] 1. Use the software Adobe Illustrate CS5 to design the screen pattern such as image 3 As shown, the black in the pattern means that the wax can pass through the screen, and the white means that the wax cannot pass through the screen. On a rectangular canvas with width and height of 160mm and 120mm respectively, two circular arrays of different sizes are designed. One type of array has a circle diameter of 8mm arranged in 4 rows and 12 columns; the other array has a circle diameter of 10mm arranged in 4 rows and 9 columns.

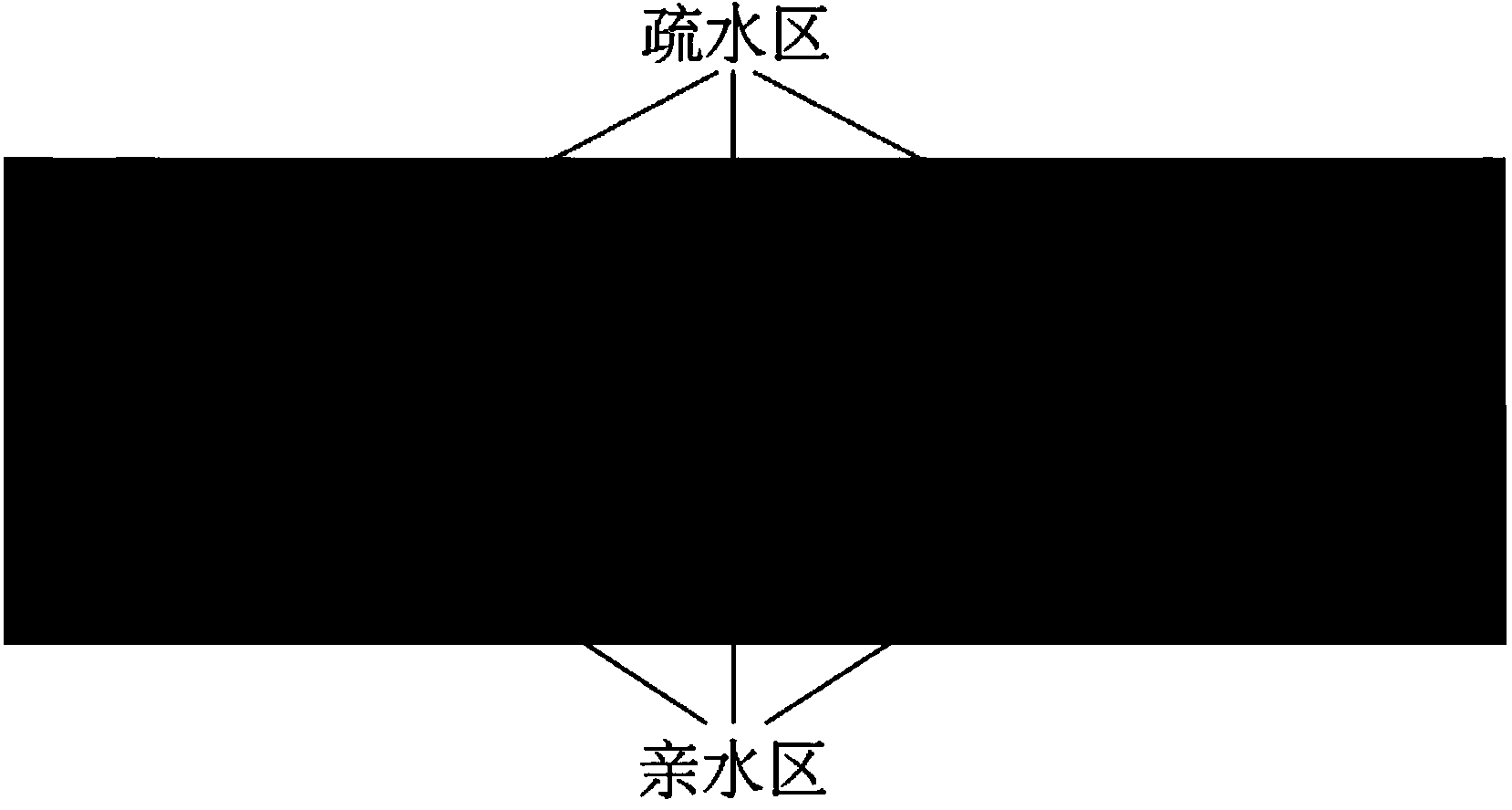

[0052] 2. The stencil made according to the stencil design pattern is as follows: Figure 4 As shown, the dark color in the stencil represents the part where the wax cannot pass through, corresponding to the formation of a hydrophilic region on the cotton substrate; the light color represents the part that the wax can pass through, correspond...

Embodiment 3

[0056] Resolution of hydrophilic channel of bucky microfluidic analysis chip

[0057] Such as Figure 6 As shown, the designed width of the hydrophilic channel of the cloth-based microfluidic analysis chip changes from 0.9mm to 2.5mm (incrementally increasing by 0.2mm). When the melting temperature and heating time were 75℃ and 5s, respectively, the carmine dye solution could fill the hydrophilic channel with a designed width greater than 1.9mm. However, when the melting temperature remains constant, the carmine dye solution cannot be successfully filled even in the hydrophilic channel with the largest designed width (2.5 mm) only by increasing the heating time to 10 s and 15 s. Therefore, the minimum width of the hydrophilic channel of the cloth-based microfluidic analysis chip processed by wax screen printing can reach 1.9mm. After the wax on the surface of the cotton cloth is heated and melted, it not only penetrates vertically into the cotton cloth, but also spreads to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Circle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com