Tight type yarn waxing mechanism for spinning

A fastening type, yarn technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of the contact area between yarn and wax block, poor waxing effect on yarn, etc., to achieve The effect of simple structure, improved quality and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

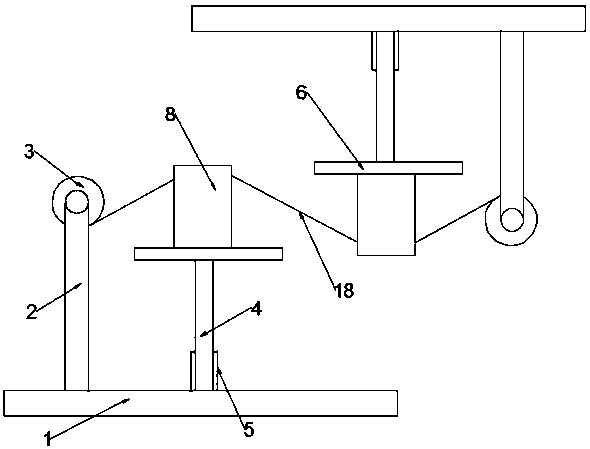

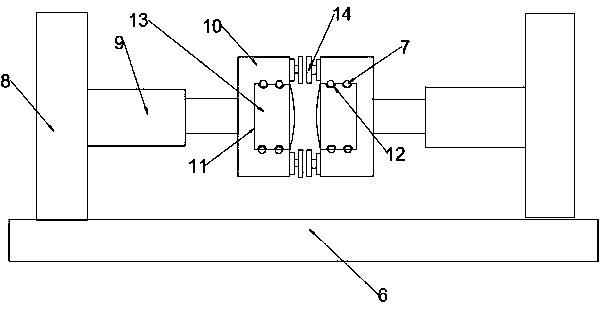

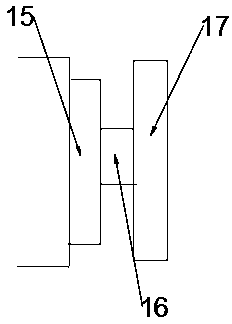

[0019] see Figure 1-3 , a fastening type textile yarn waxing mechanism, comprising a first waxing part and a second waxing part, the first waxing part and the second waxing part each include a base 1, a support rod 2, a guide Wheel 3, telescopic tube, support plate 6, air pump 8, fixed part 10 and wax block 13, described support bar 2 and telescopic tube are all installed on the base 1 and are used for installing the guide wheel 3 of yarn 18 to be arranged on the support bar 2, the support plate 6 is fixed on the top of the telescopic tube, the number of air pumps 8 is two and the two air pumps 8 are respectively installed on the front end and the rear end of the support plate 6, and the output shafts of the two air pumps 8 are connected with telescopic rods 9 and the two telescopic rods 9 are arranged correspondingly, and one end of the two tele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com