Special vibration absorber oil for railway locomotive and preparation method thereof

A shock absorber oil, railway locomotive technology, applied in the petroleum industry, only multi-stage series refining process treatment, lubricating composition, etc., can solve the problems of shock absorber oil product quality, lack of lubricating performance, low temperature performance and To solve problems such as poor shear performance, achieve the effect of improved lubricating performance, fewer steps, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

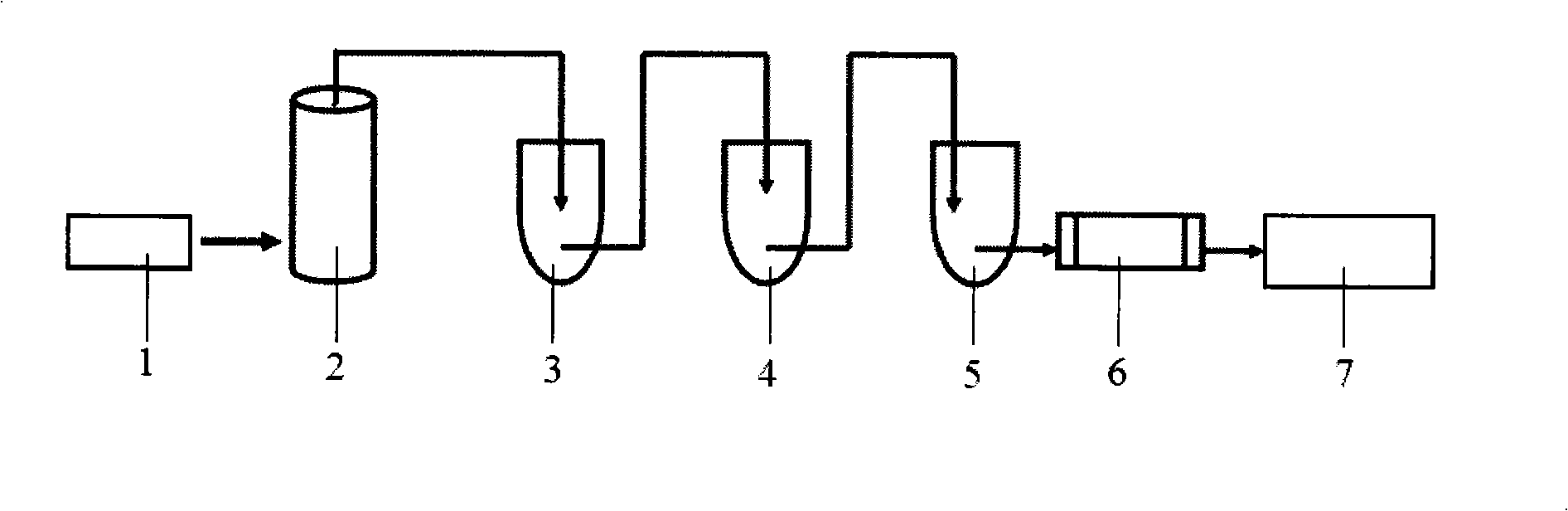

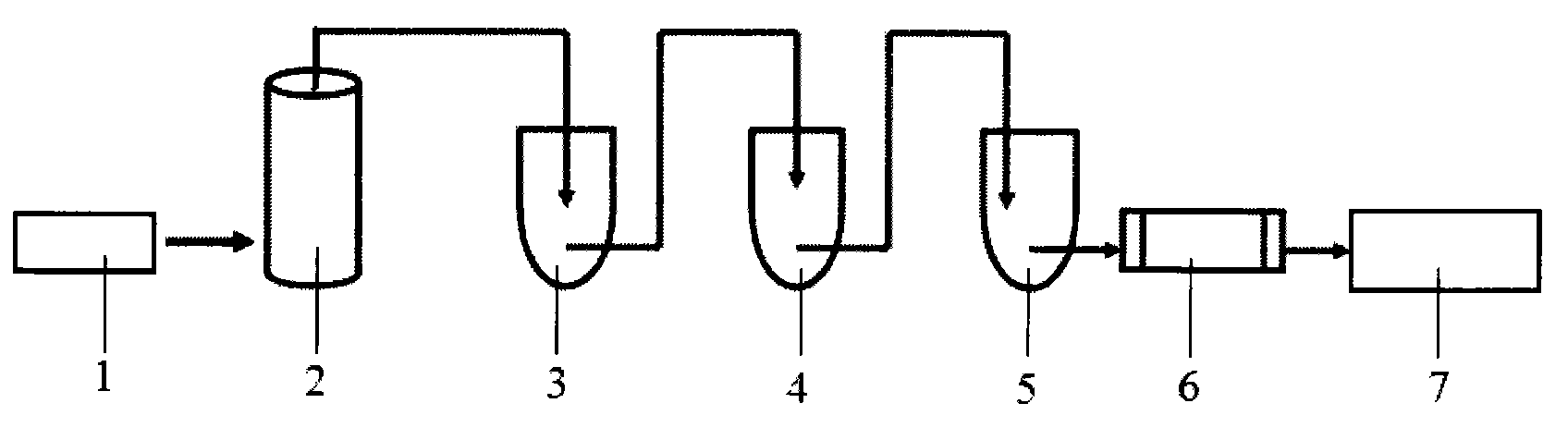

Image

Examples

Embodiment 1

[0023] A method for producing special shock absorber oil for railway locomotives, comprising the following steps:

[0024] (1) Use hydrorefined low-viscosity mineral oil as raw material, pump it into a continuous rectification tower for rectification and cutting, and cut out the base oil with a distillate of 320-370 °C;

[0025] (2) Inputting the base oil into a urea dewaxing device and adopting a wet urea dewaxing process for deep dewaxing at a temperature of 30-40° C. to produce dewaxed oil whose pour point is below -50° C.;

[0026] (3) pump the dewaxed oil into the clay refining kettle, heat to 80°C, add 2% clay by weight, heat and stir for 30 minutes, and filter through a filter press to obtain the special base oil;

[0027] (4) Pump 4350kg of special base oil into the pulse blending reaction kettle, heat it to 80°C while stirring, then add 487.7kg of viscosity index improver H638, keep stirring for 50 minutes, then continue to stir and cool to 70°C ℃; then add 39kg of c...

Embodiment 2

[0032] A method for producing special shock absorber oil for railway locomotives, comprising the following steps:

[0033] (1) Use light oil as raw material, pump it into the continuous rectification tower for rectification and cutting, and cut out the base oil with a fraction of 320-370°C;

[0034] (2) Inputting the base oil into a urea dewaxing device and adopting a wet urea dewaxing process for deep dewaxing at a temperature of 30-40° C. to produce dewaxed oil whose pour point is below -50° C.;

[0035] (3) pump the dewaxed oil into the clay refining kettle, heat to 85°C, add 2% clay by weight, heat and stir for 30 minutes, and filter through a filter press to obtain the special base oil;

[0036] (4) Pump 4400kg of special base oil into the pulse blending reaction kettle, heat to 75°C while stirring, then add 550.1kg of viscosity index improver H638, keep stirring for 45 minutes, then continue to stir and cool to 70°C ℃; then add 50.0kg of compounding agent T5092 and 0.35...

Embodiment 3

[0042] A method for producing special shock absorber oil for railway locomotives, comprising the following steps:

[0043] (1) Use special white oil as raw material, pump it into the continuous rectification tower for rectification and cutting, and cut out the base oil whose distillate is 320-370°C;

[0044] (2) Inputting the base oil into a urea dewaxing device and adopting a wet urea dewaxing process for deep dewaxing at a temperature of 30-40° C. to produce dewaxed oil whose pour point is below -50° C.;

[0045] (3) pump the dewaxed oil into the clay refining kettle, heat to 90°C, add 4% clay by weight, heat and stir for 40 minutes, and filter through a filter press to obtain the special base oil;

[0046] (4) Pump 4300kg of special base oil into the pulse blending reaction kettle, heat it to 80°C while stirring, then add 594.6kg of viscosity index improver H638, keep stirring for 50 minutes, then continue to stir and cool to 70°C ℃; then add 59.5kg of compounding agent T5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com