Damping yarn waxing mechanism for spinning

A shock-absorbing effect and yarn technology, which is applied in textiles and papermaking, can solve the problems of affecting the use of yarn, not being able to wax the yarn, and the yarn is easy to wear, so as to improve the quality, reduce the yarn loss and ensure the accuracy degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be further described in detail below.

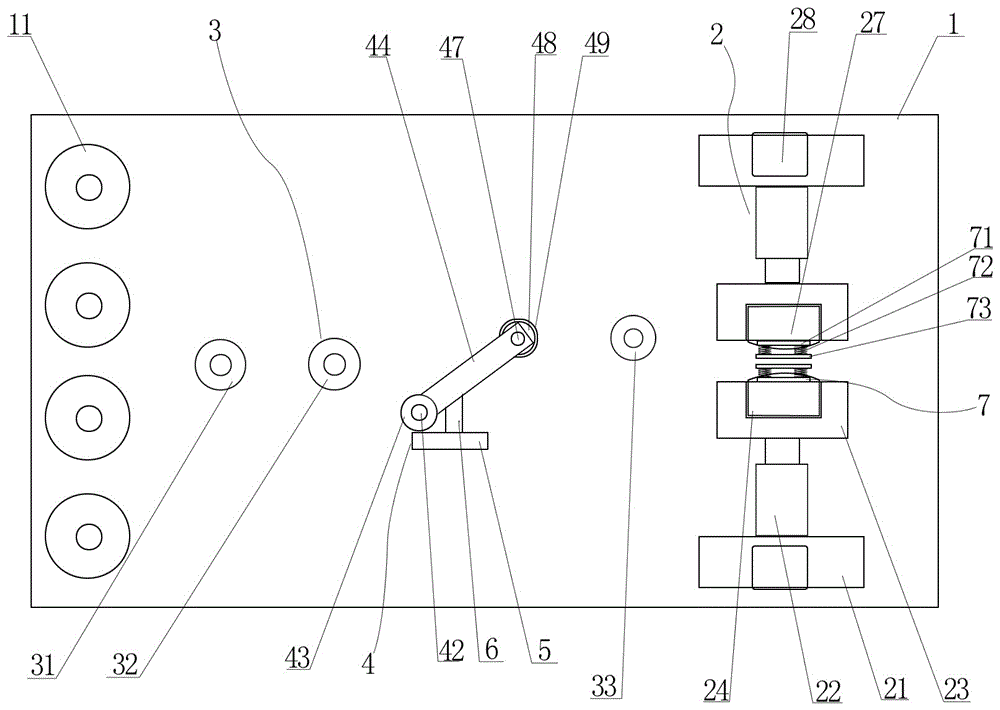

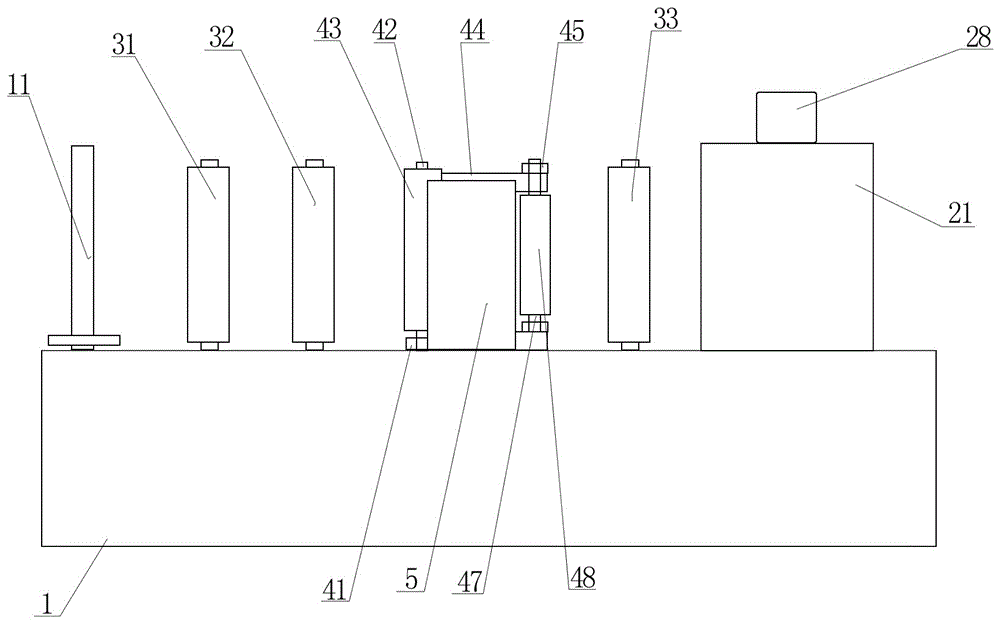

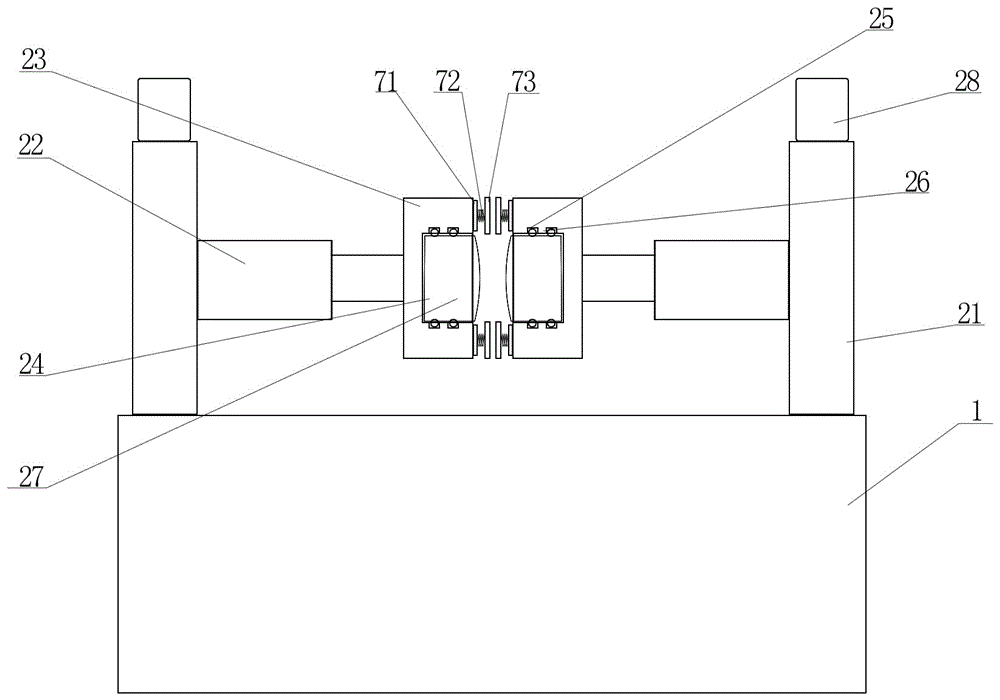

[0015] like Figure 1 to Figure 3 As shown, a kind of textile yarn waxing mechanism with damping effect of the present invention includes a frame 1, a waxing assembly 2 and a wire transmission assembly 3 are arranged on the frame 1, and the waxing assembly 2 includes a The vertical plates 21 on both sides of the frame 1, the adjacent side of the vertical plates 21 are all correspondingly connected with a telescopic rod 22, the telescopic rod 22 is horizontally arranged, and one end of the two telescopic rods 22 is correspondingly provided with a fixed box 23, and the two fixed boxes The adjacent side of 23 is all correspondingly provided with a groove 24, and the wax block 27 that is used for waxing on the yarn is arranged in the groove 24, and the upper and lower sides of groove 24 are all provided with a plurality of round grooves 25, and in the groove 25 Both are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com