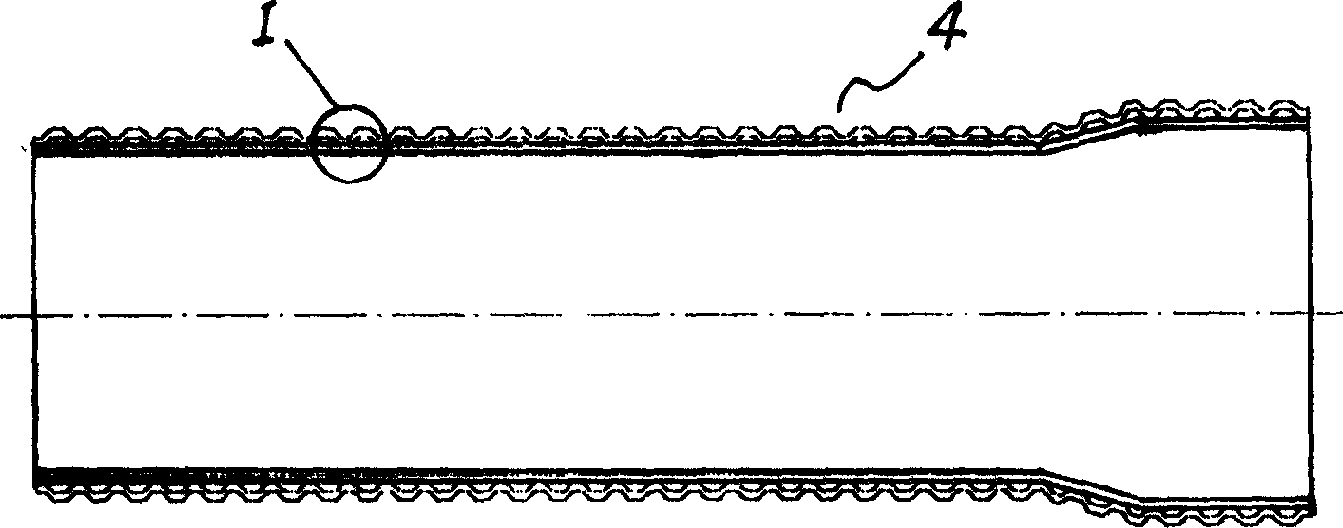

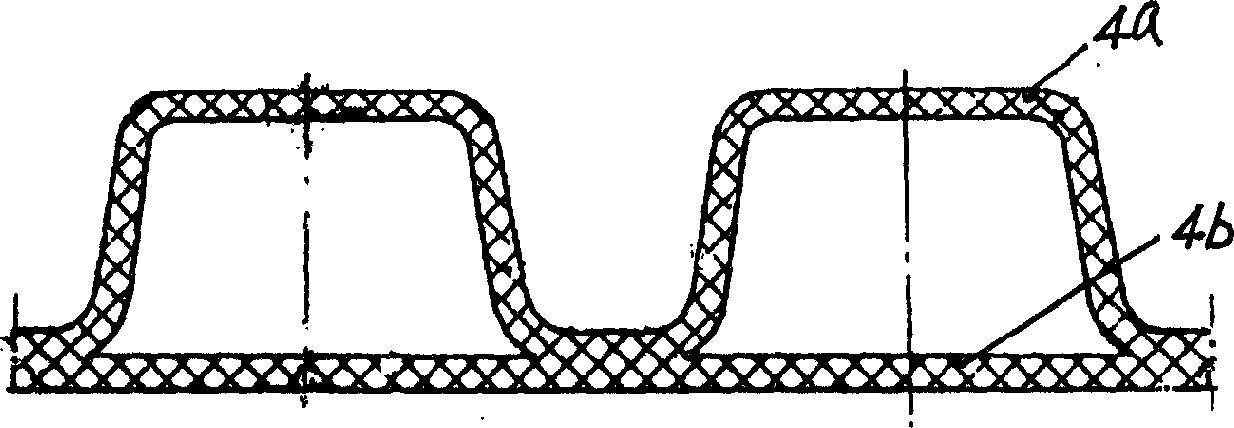

Process for producing large caliber hard polyvinyl chloride double wall corrugated pipe

A technology of double-wall corrugated pipe and rigid polyvinyl chloride, which is applied in the field of manufacturing rigid polyvinyl chloride double-wall corrugated pipe, can solve the problems of inability to produce large diameters, achieve qualified quality and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1. The production process of the large-caliber rigid polyvinyl chloride double-wall corrugated pipe in this embodiment contains the following steps in sequence:

[0026] 1) Raw materials: the unit of each component is parts by weight PVC resin (i.e. polyvinyl chloride resin) 100

[0027] Composite stabilizer 5~7

[0028] Stearic acid 0.9~1.5

[0029] PE wax (ie polyethylene wax) 0.4~1.0

[0030] Chlorinated polyethylene 4~6

[0032] In the above-mentioned preparation materials, the high-performance composite stabilizer is the SMR50354 composite stabilizer produced by the German Bear brand company purchased from the domestic market, which can be used as a stable distribution system for materials; calcium carbonate is a kind of superfine activated PVC Fillers are used to ensure ...

Embodiment 2

[0038] Embodiment 2. The production process of the large-diameter rigid polyvinyl chloride double-wall corrugated pipe of this embodiment is different from that of Embodiment 1 in that: in the process of preparing materials, in addition to strict weighing, each group of ingredients must be weighed. Reweighing monitoring and zero point calibration of measuring instruments to ensure accurate measurement.

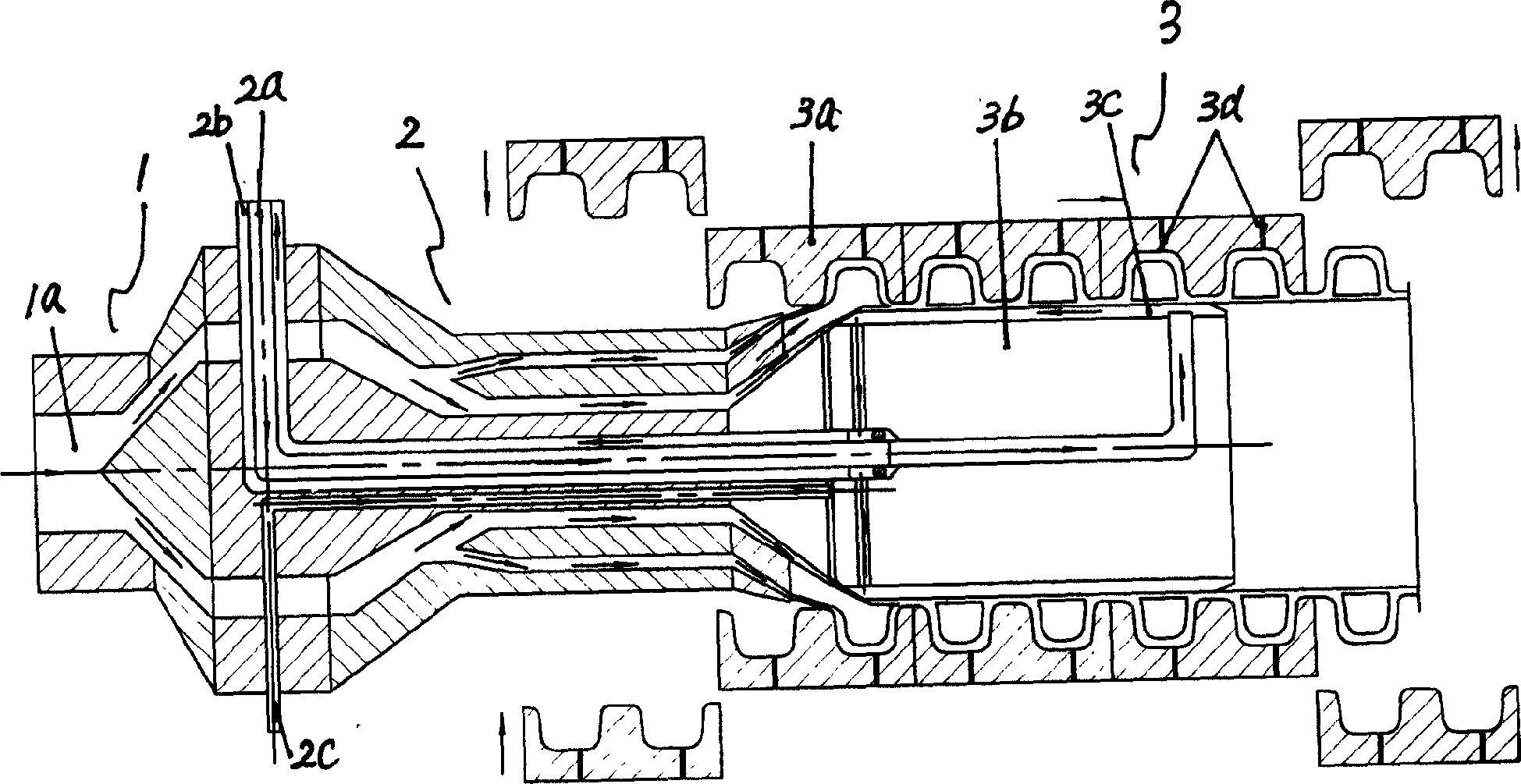

[0039] The twin-screw extruder in this embodiment adopts the most advanced SJSZ-95 / 191 conical twin-screw extruder in China, and its extrusion capacity per hour can reach 11000kg, which can effectively ensure Sufficient plasticization of materials and material supply required for continuous molding of large-diameter corrugated pipes.

[0040] The extrusion die head in this embodiment is made of forged blank made of high-quality alloy steel, which is subjected to full numerical control processing after quenching and tempering heat treatment. Because in the production process o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com