Preparation method of oil-resistant room temperature vulcanization deoximation silicon rubber

A technology of room temperature vulcanization and silicone rubber, which is applied in the field of room temperature curable silicone rubber, which can solve the problems of high cost, limited application, and poor non-polar oil resistance of silicone rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Set the kinematic viscosity to 20000 mm 2 / s of α, ω-dihydroxy polydimethylsiloxane and light calcium carbonate after stearic acid surface treatment are stirred in a kneader; add vinyl tributylketoximosilane for full stirring; add gas phase method The white carbon black is fully stirred; after adding the reactant of aminopropyltriacetoneximosilane and 3-isocyanatopropyltrimethoxysilane and dibutyltin dilaurate and fully stirring, the product is obtained by gelling.

[0021] serial number components Dosage / serving 1 α,ω-Dihydroxypolydimethylsiloxane 80 2 calcium carbonate 120 3 Vinyl tributylketoxime silane 10 4 Fumed silica 15 5 Reaction product of aminopropyltriacetoneximosilane and 3-isocyanatopropyltrimethoxysilane 2 6 Dibutyltin dilaurate 1.5

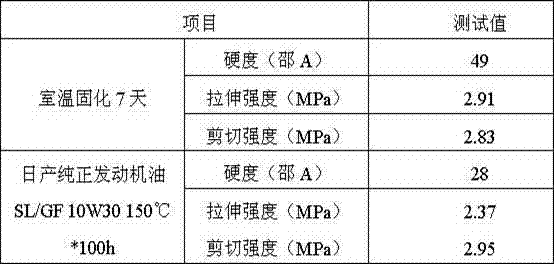

[0022] Oil resistance

[0023]

Embodiment 2

[0025] Set the kinematic viscosity to 50000 mm 2 / s of α, ω-dihydroxy polydimethylsiloxane and light calcium carbonate after stearic acid surface treatment are stirred in a kneader; add methyl tributylketoximosilane for full stirring; add gas phase method The white carbon black is fully stirred; after adding the reactant of aminopropyl tributylketoxime silane and 3-isocyanatopropyl triethoxysilane and dioctyltin dilaurate and fully stirring, the product is obtained by gelling.

[0026] serial number components Dosage / serving 1 α,ω-Dihydroxypolydimethylsiloxane 30 2 calcium carbonate 30 3 Methyltributanoximinosilane 5 4 Fumed silica 5 5 Reactant of Aminopropyltributanoximinosilane and 3-Isocyanatopropyltriethoxysilane 1.5 6 Dioctyltin dilaurate 1

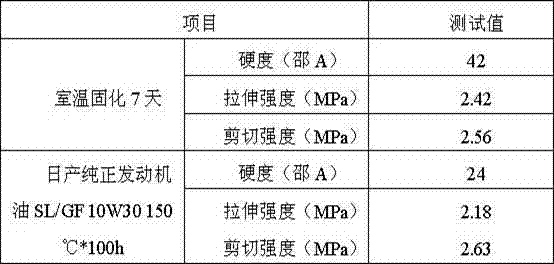

[0027] Oil resistance

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com