Material special for PVC-M feed pipe member and production method thereof

A technology for water supply pipe fittings and special materials, which is applied in the field of special materials for PVC-M water supply pipe fittings and its preparation, can solve the problems of insignificant impact resistance and the like, and achieve the effects of good forming processability, good thermal stability and good toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

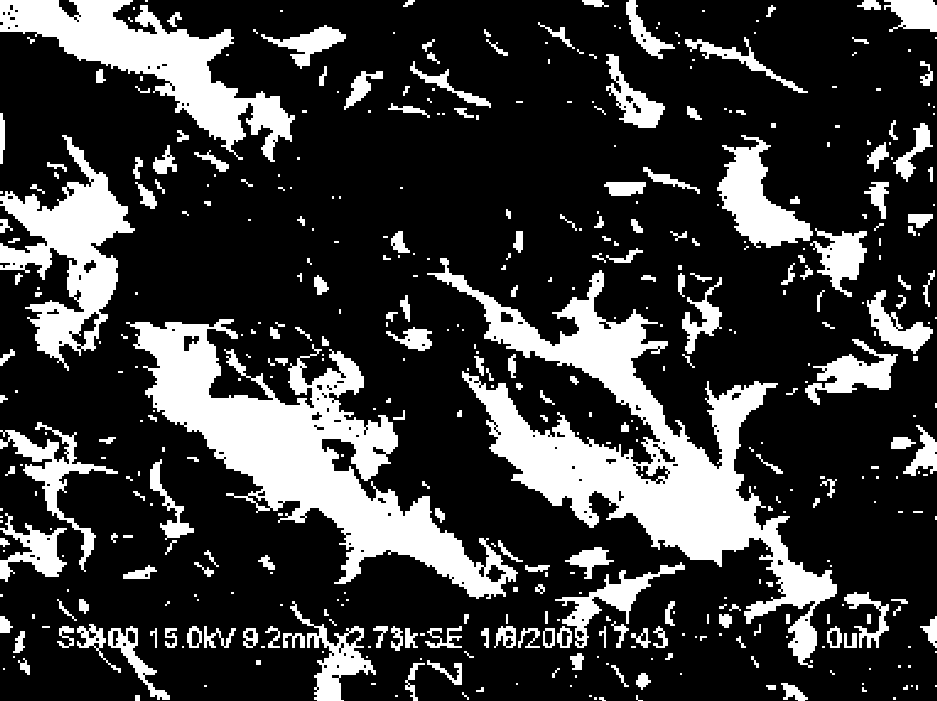

Image

Examples

Embodiment 1

[0023] The special material for PVC-M water supply pipe fittings of this embodiment includes 75kg of S-700 type PVC resin, 5.6kg of MBS, 2.2kg of butyltin maleate, 2.1kg of polyethylene wax, 4.2kg of methyl acrylate, 0.3kg Titanium dioxide and 4.5kg of calcium carbonate treated with a silica gel coupling agent.

[0024] The preparation method of the PVC-M special material for water supply pipe fittings of the present embodiment is:

[0025] ① Weigh 75kg of S-700 PVC resin, 5.6kg of MBS, 2.2kg of butyltin maleate, 2.1kg of polyethylene wax, 4.2kg of methyl acrylate, and 0.3kg of titanium dioxide for use;

[0026] ②Pour 4kg of calcium carbonate and 0.5kg of silica gel coupling agent into a high-speed mixer and mix at a temperature of 130°C for 8 minutes, then discharge and cool for use;

[0027] ③Pour S-700 type PVC resin into a high-speed kneader and mix to 90°C, then pour butyltin maleate into a high-speed mixer and continue mixing, then add MBS, polyethylene wax, methyl acry...

Embodiment 2

[0030] The special material for PVC-M water supply pipe fittings of this embodiment includes 75kg of S-700 type PVC resin, 6.5kg of CPE, 2.5kg of tin mercaptide, 2.0kg of stearic acid, 1.5kg of butyl acrylate, 0.4 kg of titanium dioxide and 3 kg of calcium carbonate treated with a silica gel coupling agent, wherein the silica gel coupling agent is 0.3 kg.

[0031] The preparation method is basically the same as in Example 1, and the performance tests are shown in Table 1 and Table 2.

Embodiment 3

[0033] The special material for PVC-M water supply pipe fittings of this embodiment includes 75kg of S-800 type PVC resin, 7.0kg of MBS, 2.2kg of tin mercaptide, 1kg of stearic acid, 1.3kg of polyethylene wax, 2.0kg Methyl acrylate and 5.0kg of calcium carbonate treated with a silica gel coupling agent, wherein the silica gel coupling agent is 0.5kg.

[0034] The preparation method is basically the same as in Example 1, and the performance tests are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com