Artificial zero-thans fatty acid cream

A technology of margarine and fatty acid, which is applied in the production/processing of edible oil/fat, etc. It can solve the problems of insufficient whipping and long-term storage, and achieve the effect of good whipping, easy preservation, and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

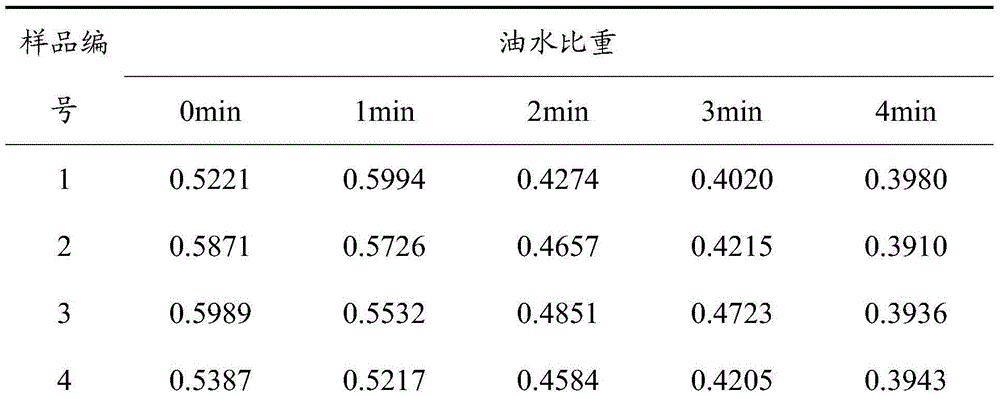

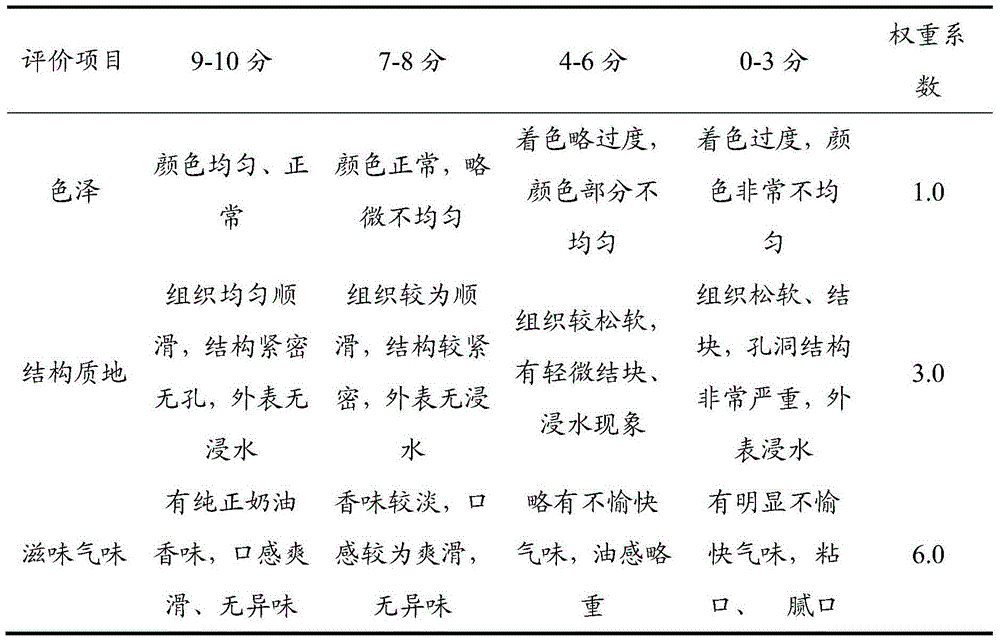

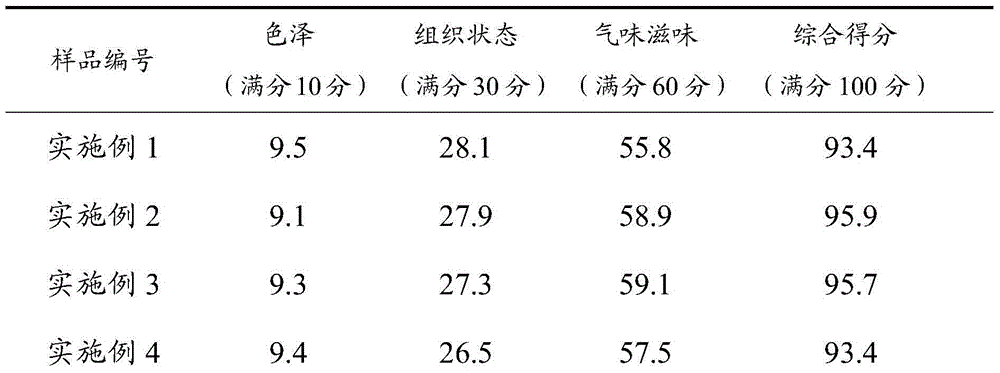

Examples

Embodiment 1

[0029] To prepare zero trans fatty acid margarine:

[0030] Prepare the oil phase:

[0031] Prepare the oil phase according to the following parts by weight: 8 parts of natural coconut oil, 12 parts of palm stearin, 2 parts of shea butter, 0.5 part of pomegranate seed oil, after mixing evenly, add 0.5 part of diglyceride and 0.5 part of lecithin , 0.5 parts of vitamin E, heat to 60°C, let the oil melt completely, mix well and set aside;

[0032] Prepare the aqueous phase:

[0033] Prepare the water phase according to the following parts by weight: add 1 part of milk powder and 0.5 part of table salt to 8 parts of deionized water, and stir well to completely dissolve it into a uniform water phase for later use;

[0034] emulsification:

[0035] Add and mix the oil phase and the water phase into the emulsification tank according to the weight ratio of 8:2 for emulsification. At the same time, add 20ppm of ascorbyl palmitate and stir while adding. The emulsification temperatur...

Embodiment 2

[0039] To prepare zero trans fatty acid margarine:

[0040] Prepare the oil phase:

[0041] Prepare the oil phase according to the following parts by weight: 9 parts of natural coconut oil, 10 parts of palm stearin, 3 parts of shea butter, 0.5 part of pomegranate seed oil, after mixing evenly, add 0.5 part of diglyceride and 0.5 part of lecithin , 0.5 part vitamin E, heat to 50°C, let the oil melt completely, mix well and set aside;

[0042] Prepare the aqueous phase:

[0043] Prepare the water phase according to the following parts by weight: add 1 part of milk powder and 0.5 part of table salt to 8 parts of deionized water, and stir well to completely dissolve it into a uniform water phase for later use;

[0044] emulsification:

[0045] Add and mix the oil phase and the water phase into the emulsification tank according to the weight ratio of 8:2 for emulsification. At the same time, add 20ppm of ascorbyl palmitate and stir while adding. The emulsification temperature is...

Embodiment 3

[0049] To prepare zero trans fatty acid margarine:

[0050] Prepare the oil phase:

[0051] Prepare the oil phase according to the following parts by weight: 8 parts of natural coconut oil, 11 parts of palm stearin, 2 parts of shea butter, 0.5 part of pomegranate seed oil, after mixing evenly, add 0.5 part of diglyceride and 0.5 part of lecithin , 0.5 parts of vitamin E, heat to 53°C, let the fat melt completely, mix well and set aside;

[0052] Prepare the aqueous phase:

[0053] Prepare the water phase according to the following parts by weight: add 1 part of milk powder and 0.5 part of table salt to 8 parts of deionized water, and stir well to completely dissolve it into a uniform water phase for later use;

[0054] emulsification:

[0055] Add and mix the oil phase and the water phase into the emulsification tank according to the weight ratio of 8:2 for emulsification. At the same time, add 20ppm of ascorbyl palmitate and stir while adding. The emulsification temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com