Method for preparing selective catalytic reduction and denitration catalyst by boiler coal ash

A denitration catalyst and fly ash technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as high cost, hindering large-scale application and promotion, and reducing catalyst denitration activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

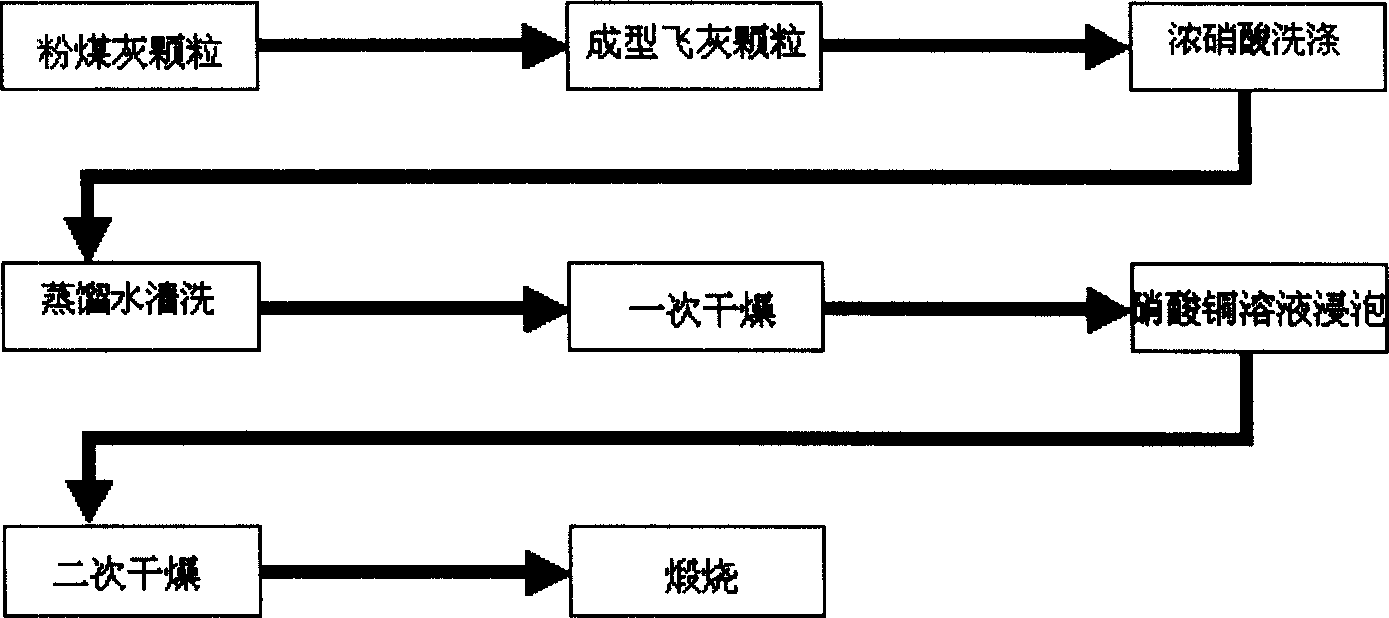

[0031] Referring to Fig. 1, the steps of the inventive method are as follows:

[0032] ① Fly ash forming: The fly ash in the tail dust removal device of the pulverized coal combustion boiler, the lime and gypsum powder in the additive, the ordinary portland cement and the aluminum oxide powder particles are respectively 80% to 82% according to the mass ratio. 15% to 16%, 3% to 4% and 0.04% to 1% are mixed for the purpose of effectively increasing the specific surface area of fly ash and increasing the number of fly ash micropores. After the stirred mixture is left to stand for 30-60 minutes, it is sent into a pretreatment tank, and the mixture is molded for more than 8 hours by using high-temperature and high-pressure steam with a temperature of 850-950°C and a pressure of 80-100 standard atmospheres. Activate pretreatment. The molded fly ash solid blocks are mechanically crushed and screened to obtain molded fly ash particles with a particle size ranging from 0.3 to 1 mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com