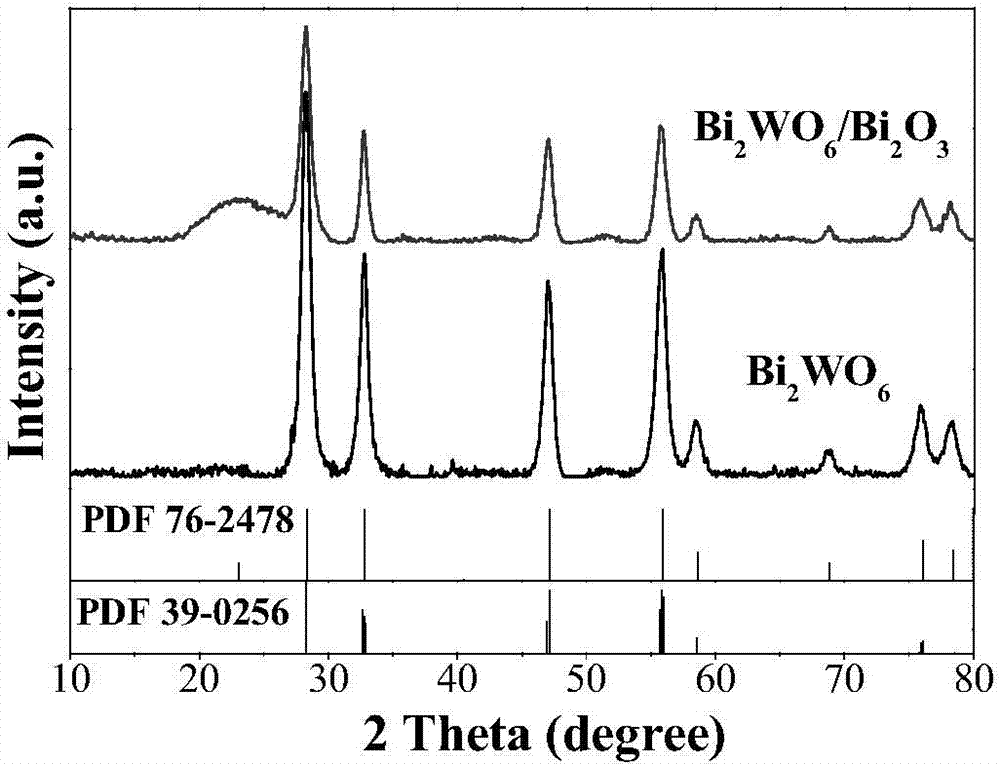

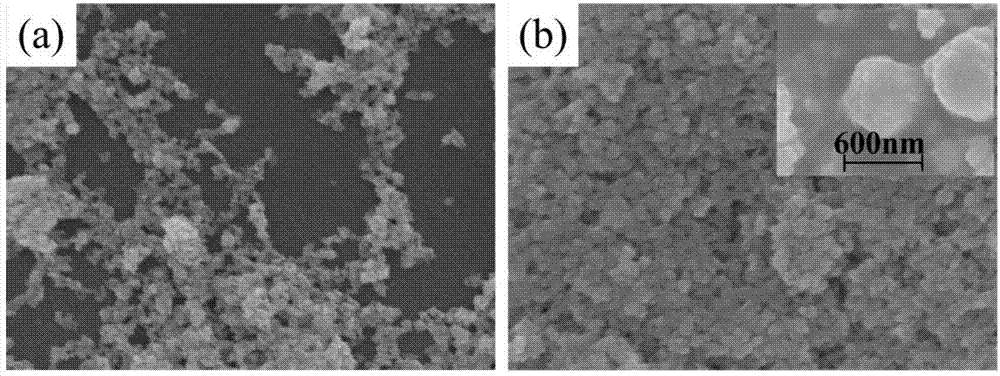

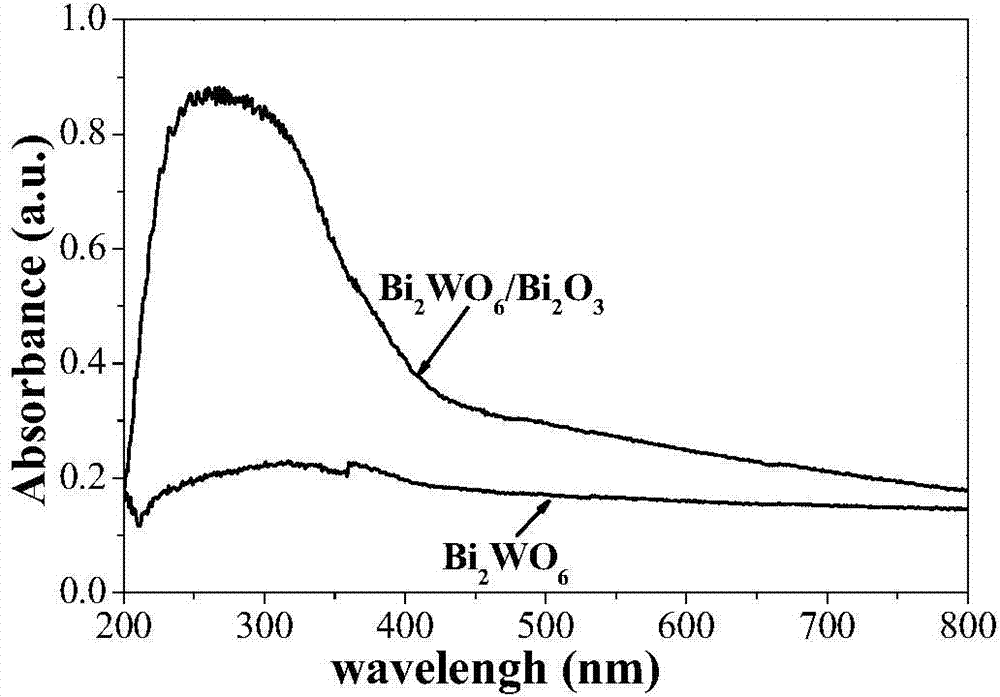

Visible light responded load type Bi2WO6/Bi2O3 heterojunction photocatalyst and preparation method thereof

A photocatalyst and visible light technology, which is applied in the direction of light water/sewage treatment, etc., can solve the problems of reduced practical applicability of photocatalytic technology, reduced photocatalytic activity of photocatalytic materials, and easy agglomeration of particles, achieving high visible light absorption capacity and preparation The condition is non-toxic and has no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method for preparing a visible light-responsive loaded Bi2WO6 / Bi2O3 heterojunction photocatalyst, comprising the following steps:

[0041] A At room temperature, dissolve 1.0g-1.5g sodium oleate into 30ml-50ml ethylene glycol solution to make a mixed solution;

[0042] B Add 1.90g-2.1g bismuth nitrate to the mixed solution, stir the mixed solution until clear;

[0043] C Take 0.5g-0.8g sodium tungstate and dissolve it in 20ml-30ml ethylene glycol solution, then add it into the mixed solution in step B, and keep stirring until completely dissolved;

[0044] D Add 0.04g-0.06g graphene or 4.0g-6.0g volcanic slag, and continue to stir until evenly mixed;

[0045] E. Place the uniformly mixed solution in an autoclave, the filling amount is 80% of the autoclave capacity, and heat at 180°C for 20h;

[0046] F, after the autoclave is naturally cooled to room temperature, take out the mixture of solid and solvent, and wash off residual organic carbon with ethanol and distill...

Embodiment 1

[0050] Bi 2 WO 6 / Bi 2 o 3 Preparation method of heterojunction photocatalyst

[0051] A At room temperature, dissolve 1.22g sodium oleate into 40.00Ml ethylene glycol solution to make a mixed solution;

[0052] B adds 1.94g bismuth nitrate to the mixed solution, stirs the mixed solution until clear;

[0053] C Dissolve 0.66g of sodium tungstate in 30.00mL of ethylene glycol solution, then add it to the mixed solution in step B, and keep stirring until completely dissolved;

[0054] D adds 5g of volcanic slag, and continues to stir until it is evenly mixed;

[0055] E. Place the uniformly mixed solution in an autoclave, the filling amount is 80% of the autoclave capacity, and heat at 180°C for 20h;

[0056] F, after the autoclave is naturally cooled to room temperature, take out the mixture of solid and solvent, and wash off residual organic carbon with ethanol and distilled water;

[0057] G. After drying at 60°C for 12 hours, a supported Bi2WO6 / Bi2O3 heterojunction ph...

Embodiment 2

[0062] Bi 2 WO 6 / Bi 2 o 3 Preparation method of heterojunction photocatalyst

[0063] A At room temperature, dissolve 1.0g sodium oleate into 40.00Ml ethylene glycol solution to make a mixed solution;

[0064] B adds 1.90g bismuth nitrate to the mixed solution, stirs the mixed solution until clear;

[0065] C Dissolve 0.60g of sodium tungstate in 20.00mL of ethylene glycol solution, then add it to the mixed solution in step B, and keep stirring until completely dissolved;

[0066] D adds 5.5g of volcanic slag, and continues to stir until it is evenly mixed;

[0067] E. Place the uniformly mixed solution in an autoclave, the filling amount is 80% of the autoclave capacity, and heat at 180°C for 20h;

[0068] F, after the autoclave is naturally cooled to room temperature, take out the mixture of solid and solvent, and wash off residual organic carbon with ethanol and distilled water;

[0069] G. After drying at 60°C for 12 hours, a supported Bi2WO6 / Bi2O3 heterojunction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com