Preparation method and purpose thereof of spherical ferriferrous oxide nano particles with controllable size

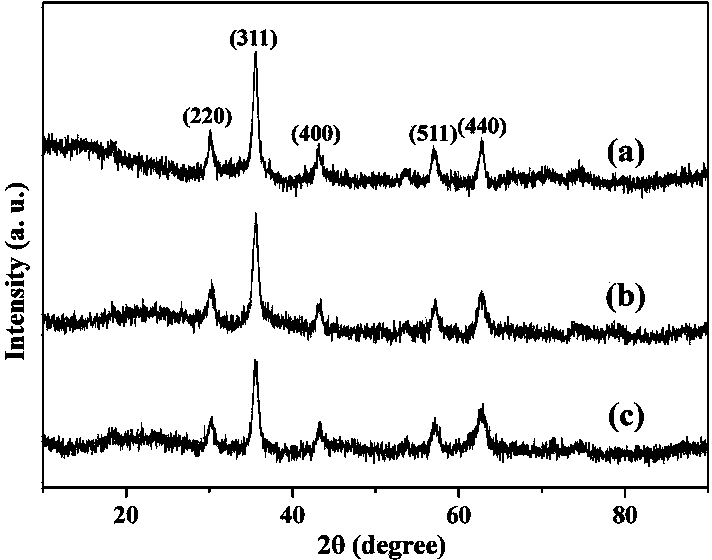

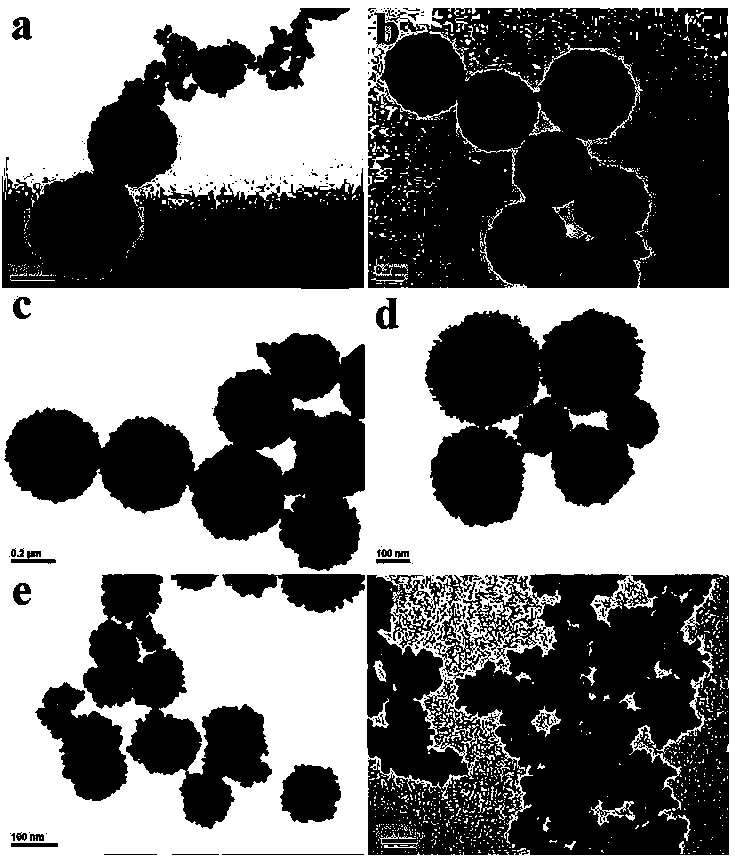

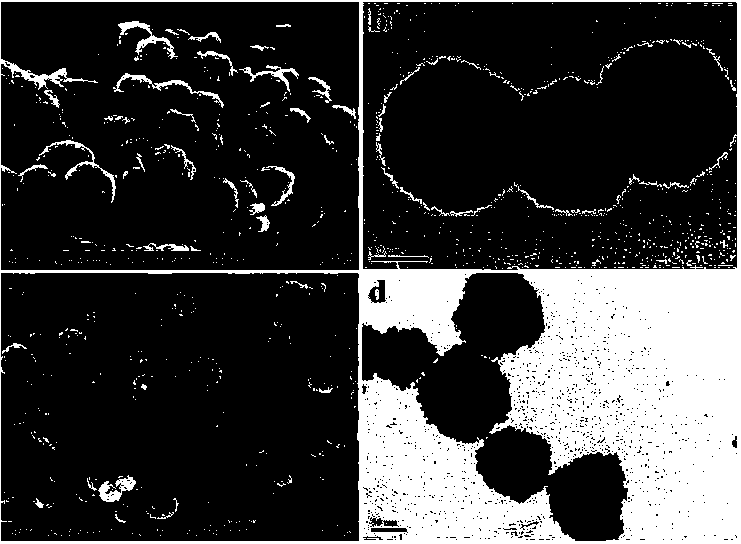

A technology of ferroferric oxide and nanoparticles, which is applied in the direction of ferrous oxide, iron oxide/iron hydroxide, electrochemical generator, etc., which can solve the complex system and does not involve the regulation of spherical ferric ferric oxide particle size and other problems, to achieve the effect of uniform size distribution, adjustable particle size and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] like Figure 4 As shown, the ferric oxide nanocrystals prepared by the present invention have excellent cycle performance, and its specific capacity can still be stabilized at 500 mAhg after 500 cycles. -1 about. In comparison, the cycle performance of ordinary ferroferric oxide electrodes is extremely poor, and the specific capacity is lower than 100 mAhg after dozens of cycles. -1 .

[0032] Example 2

Embodiment 2

[0034] Example 3

Embodiment 3

[0036] Example 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com